PMNT piezoelectric transducer for ultrasonic deicing

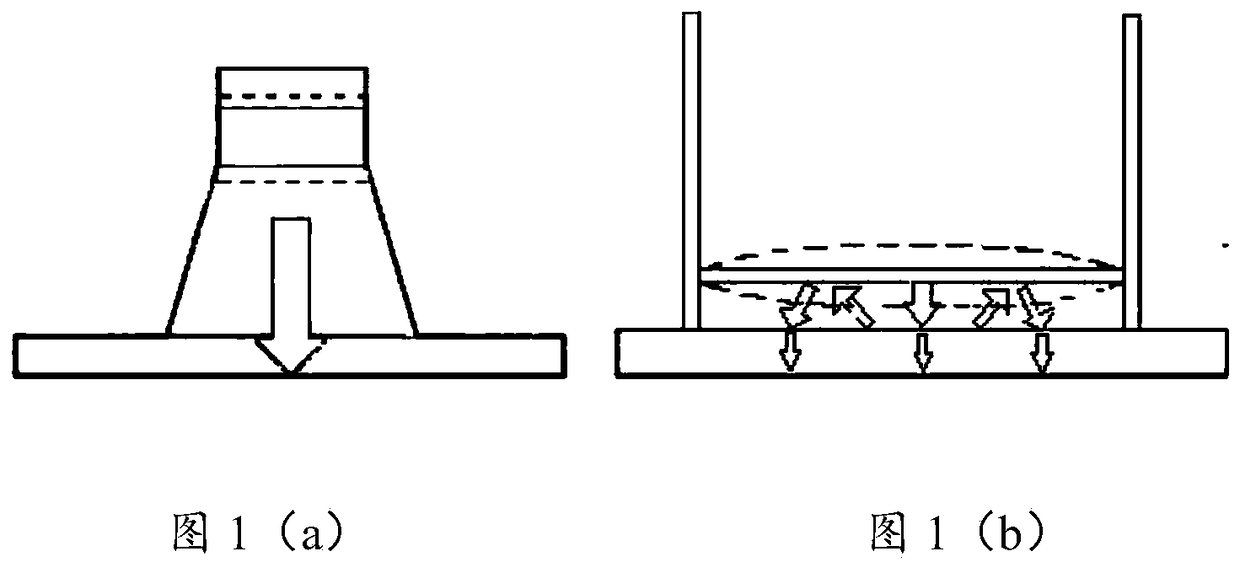

A piezoelectric transducer and ultrasonic technology, which is applied in the direction of fluid using vibration, etc., can solve the problems of unsuitability for assembly and deicing, the total weight of the transducer is large, and the volume of the front mass block is large. The effect of high processing and working frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

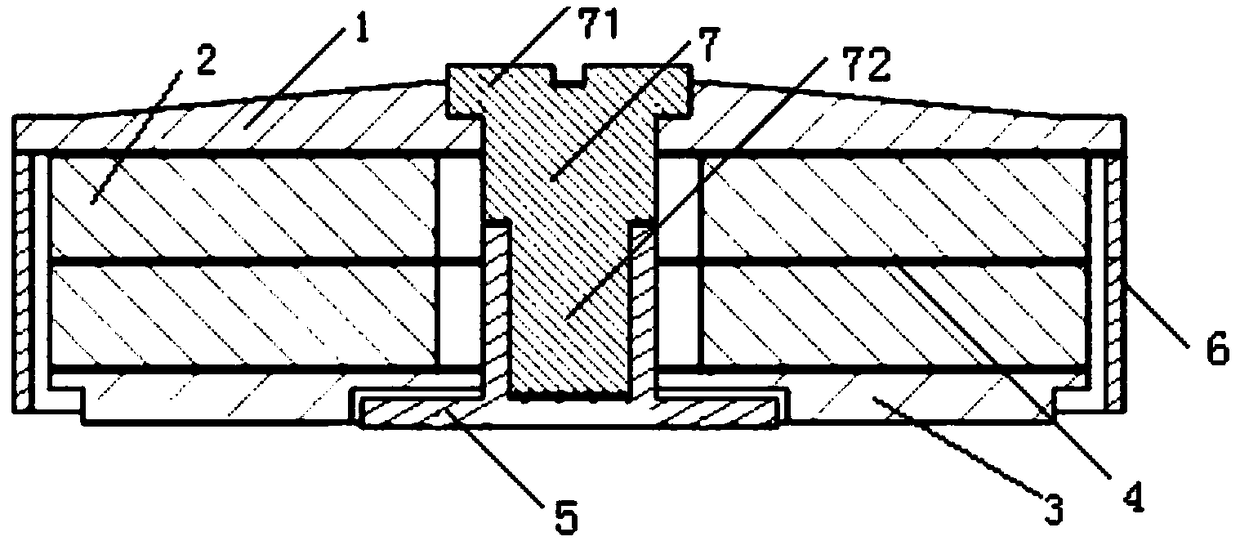

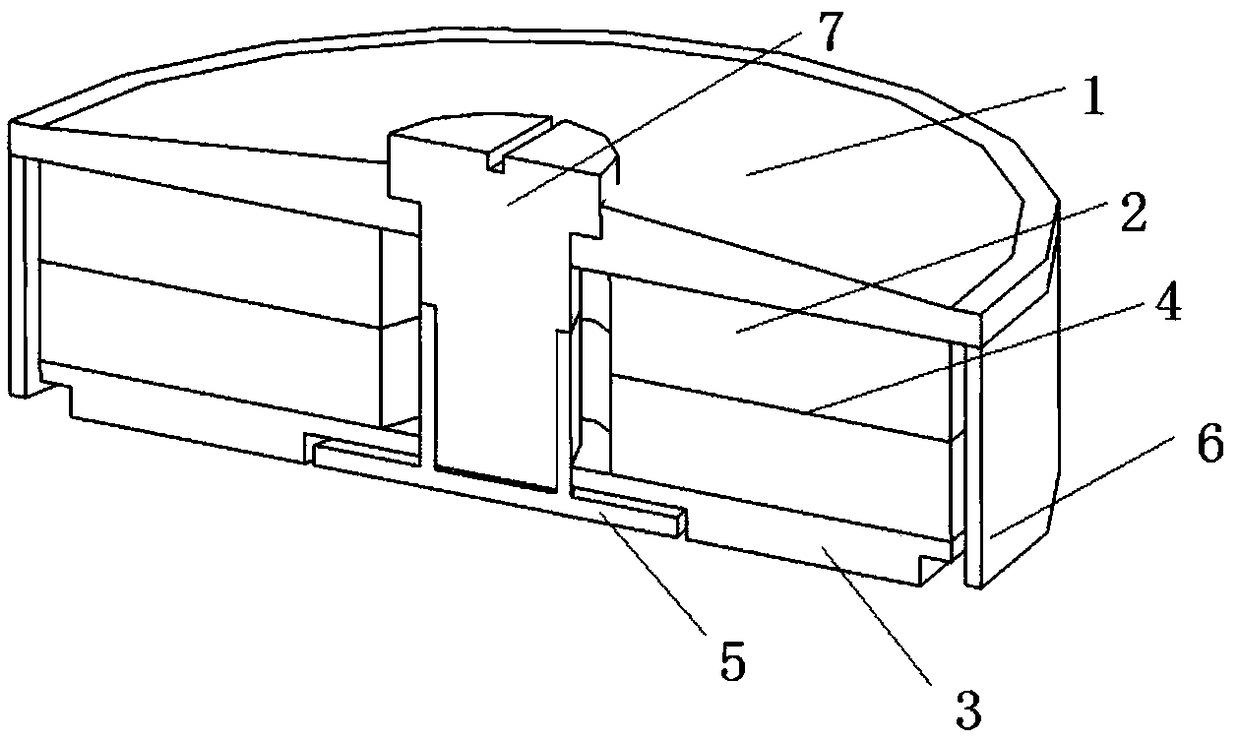

[0044] Embodiment 1: The transducer includes components such as a rear cover plate 1, a piezoelectric sheet 2, a front gasket 3, an electrode sheet 4, a circular base 5, a casing 6, and bolts 7, and two piezoelectric sheets 2 of the same thickness An electrode sheet 4 is covered between them, and two piezoelectric sheets 2 are respectively connected to the front gasket 3 and the rear cover plate 1. There is a circular base 5 in the middle of the front gasket 3, and a shell 6 is glued and fixed on the circular base 5. And the two piezoelectric sheets 2 and the electrode sheets 4 are surrounded by the casing 6, the rear cover 1, the piezoelectric sheet 2, the electrode sheet 4, and the circular base 5 are all provided with concentric holes, and the concentric holes are connected to form a connecting channel , There are prestressed adjusting bolts installed in the connecting channel.

[0045] attached Figure 4 As shown, the total thickness m of the transducer is 10.4㎜, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer radius | aaaaa | aaaaa |

| Inner radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com