Sponge water permeable brick, preparation method of sponge water permeable brick and blending device

A technology of permeable bricks and sponges, which is applied in the field of building materials and materials, and can solve problems such as poor adhesion of adhesives on the surface of permeable bricks, confusing mixing methods, and untargeted mixing equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

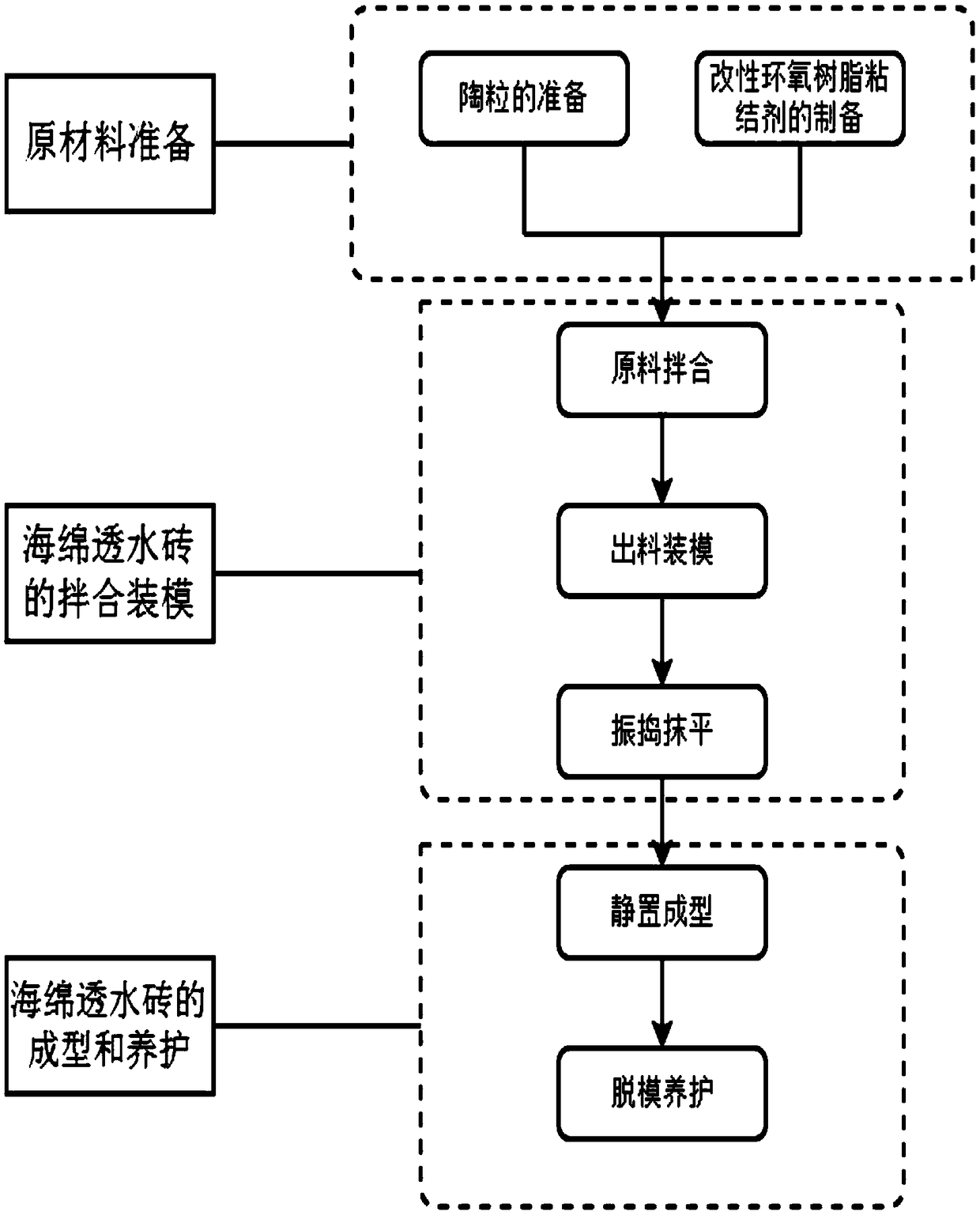

[0125] A kind of preparation method of sponge permeable brick of the present invention, its steps are as follows:

[0126] 1. Raw material preparation

[0127] The modified epoxy resin adhesive surface adhesive, modified epoxy resin adhesive adhesive surface adhesive curing agent and ceramsite in a kind of sponge permeable brick according to the present invention are prepared according to mass percentage: modified epoxy resin adhesive The binder surface glue is 5.6 or 20.8%, the modified epoxy resin adhesive surface glue curing agent is 3.4 or 12.5%, and the ceramsite is 66.7 or 91%.

[0128] 1) Preparation of ceramsite

[0129] Choose ceramsite according to different application directions of sponge permeable bricks:

[0130] (1) If it is used on non-load-bearing sponge permeable bricks of road drainage ditches and tree surrounding stones, light clay ceramsite should be selected as the raw material;

[0131] (2) If it is used on the small-load sponge permeable bricks of si...

Embodiment 1

[0158] In this embodiment, a sponge permeable brick with a size of 150mm×150mm×150mm is prepared as a non-load-bearing structural member for road drainage ditches and tree surrounding stones.

[0159] The composition and mass ratio of a sponge permeable brick is: 20.8% of modified epoxy resin adhesive surface adhesive; 12.5% of modified epoxy resin adhesive adhesive surface adhesive curing agent; 66.7% of lightweight clay ceramsite.

[0160] The cylinder compressive strength of the light clay ceramsite used is 1Mpa, the particle size is 13.2mm-16mm, the apparent density is 0.37g / cm3, and the crushing value is 86.4%;

[0161] 1) The modified epoxy resin binder comprises two parts of the modified epoxy resin binder surface glue and the modified epoxy resin binder surface glue curing agent, the modified epoxy resin binder surface glue It is a milky white solvent, and the modified epoxy resin adhesive surface adhesive curing agent is a dark brown solvent. When using it, modify t...

Embodiment 2

[0187] A sponge permeable brick with a size of 150mm×150mm×150mm prepared in this embodiment is used as a structural member for pedestrian walkways, park corridors and the like to bear relatively small loads.

[0188] The composition and mass ratio of a sponge permeable brick is: 5.6% of modified epoxy resin adhesive surface adhesive, 3.4% of modified epoxy resin adhesive adhesive surface adhesive curing agent, and 91% of high-strength ceramsite.

[0189] The cylinder compressive strength of the high-strength ceramsite used is 6-10Mpa, the particle size is 8mm, the apparent density is 1.80g / cm3, and the crushing value is 10.8%.

[0190] 1) The modified epoxy resin binder comprises two parts of the modified epoxy resin binder surface glue and the modified epoxy resin binder surface glue curing agent, the modified epoxy resin binder surface glue It is a milky white solvent, and the modified epoxy resin adhesive surface adhesive curing agent is a dark brown solvent. When using it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com