Chain grate machine-rotary kiln pellet process pre-desulfurization and denitrification method

A technology of desulfurization, denitrification, and rotary kiln, which is applied in the field of iron and steel metallurgy to achieve the effects of improving desulfurization efficiency, slowing down NH3 release, and strong thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

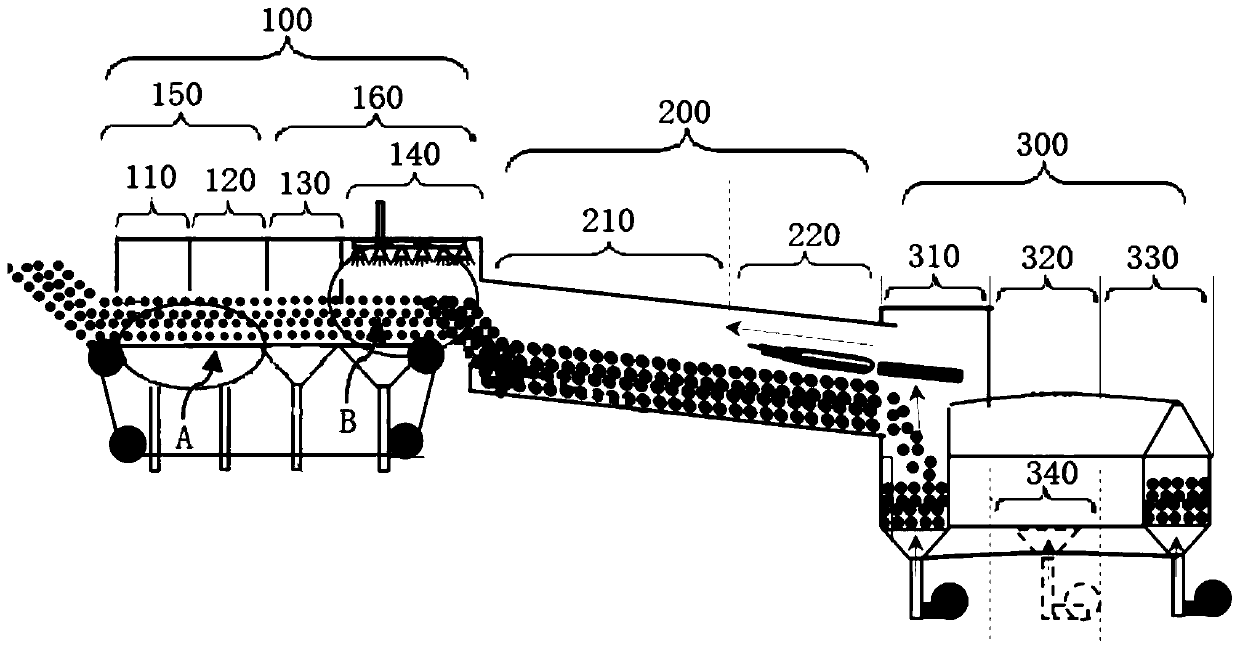

[0041] Such as figure 1 As shown, in the chain grate machine-rotary kiln pelletizing process of the present embodiment, the method for desulfurization and denitrification in advance, the drying I section 110 at the front end of the drying section 150 of the grate machine 100 adopts draft drying, and the source of hot air adopts preheating I section 130 and The mixed gas of the cooling section III section 330 of the ring cooler 300, the drying section II section 120 at the rear end of the drying section 150 is still dried by suction; and Ca is added during the preparation of green pellets. 2+ Chelate urea intercalated bentonite, install urea milling, storage, screw feeding and dry powder injection devices on the preheating II section 140 of the grate machine 100, and the injection device sprays urea powder into the preheating II section 140 to make the smoke The content of NOx and SOx in the air is significantly reduced.

[0042] In this embodiment, the chain grate machine-rot...

Embodiment 2

[0062] The chain grate machine-rotary kiln pelletizing process pre-desulfurization and denitrification method of this embodiment is basically the same as the above embodiment, the difference is that in this embodiment Ca 2+ The chelated urea intercalation bentonite comprises the following components in terms of mass percentage: 2.5wt.% urea, 2.5wt.% Ca(OH) 2 and 95wt.% bentonite, when prepared:

[0063] P2. Stir and heat the mixed solution at a constant temperature for 3 hours at 100°C;

[0064] P3, the quality of adding bentonite to the above melt is Ca(OH) 2 and 19 times the mass sum of urea, and add 8wt.% water by mass percentage, and then stir evenly;

[0065] P4. Place the mixture at room temperature for 10 hours, then place it in a microwave heating furnace with the temperature controlled at 80°C, heat for 2 hours, and then finely grind the agglomerated material to a particle size of less than 0.074mm and a content of ≥95wt.%.

[0066] When using, add 1.0wt.% Ca durin...

Embodiment 3

[0068] The chain grate machine-rotary kiln pelletizing process pre-desulfurization and denitrification method of this embodiment is basically the same as the above embodiment, the difference is that in this embodiment Ca 2+ The chelated urea intercalated bentonite comprises the following components in terms of mass percentage: 10wt.% of urea, 10wt.% of Ca(OH) 2 and 80wt.% bentonite, when prepared:

[0069] P2. Stir and heat the mixed solution at a constant temperature for 0.5h at 120°C;

[0070] P3, the quality of adding bentonite to the above melt is Ca(OH) 2 and 4 times the mass sum of urea, and add 5wt.% water by mass percentage, and then stir evenly;

[0071] P4. Put the mixture at room temperature for 14 hours, then place it in a microwave heating furnace, control the temperature at 100°C, heat it for 0.5 hours, and then finely grind the agglomerated material to a particle size of less than 0.074mm and the content is ≥95wt.%.

[0072] When using, add 4.0wt.% Ca during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com