Wireless measurement and control separate injection pipe column of water injection well

A water injection well, wireless technology, used in measurement, wellbore/well components, production fluids, etc., can solve the problems of wireless transmission mode signal attenuation, affecting the life of the pipe string, short transmission distance, etc., to eliminate the risk of collision damage, The effect of improving the technical level and alleviating the lack of measurement and adjustment power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments are listed below and shown in the accompanying drawings in detail as follows.

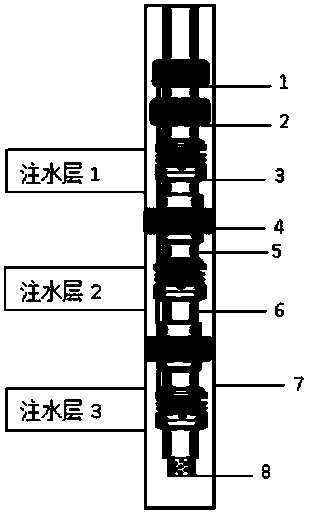

[0017] Such as figure 1 as shown, figure 1 It is a structural diagram of the wireless measurement and control dispensing string of the water injection well of the present invention. The water injection well wireless measurement and control injection string includes downhole pressure pulse transceiver device 1, downhole power supply 2, flow measurement and control device 3, cable packer 4, signal cable 5, tubing 6, casing 7, and well flushing valve 8.

[0018] The injected water enters the oil pipe 6 and flows downward until each water injection layer corresponds to the flow measurement and control device 3. The downhole pressure pulse transceiver device 1 receives the pressure signal sent by the surface pressure pulse transceiver device and converts i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com