Safety blowdown and discharge tool of ball valve DN100 and below for natural gas pipeline

A natural gas pipeline and venting technology, which is applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of difficult collection of exhaust, loud exhaust airflow, and airflow impact damage, saving time and effort. , Simple structure and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

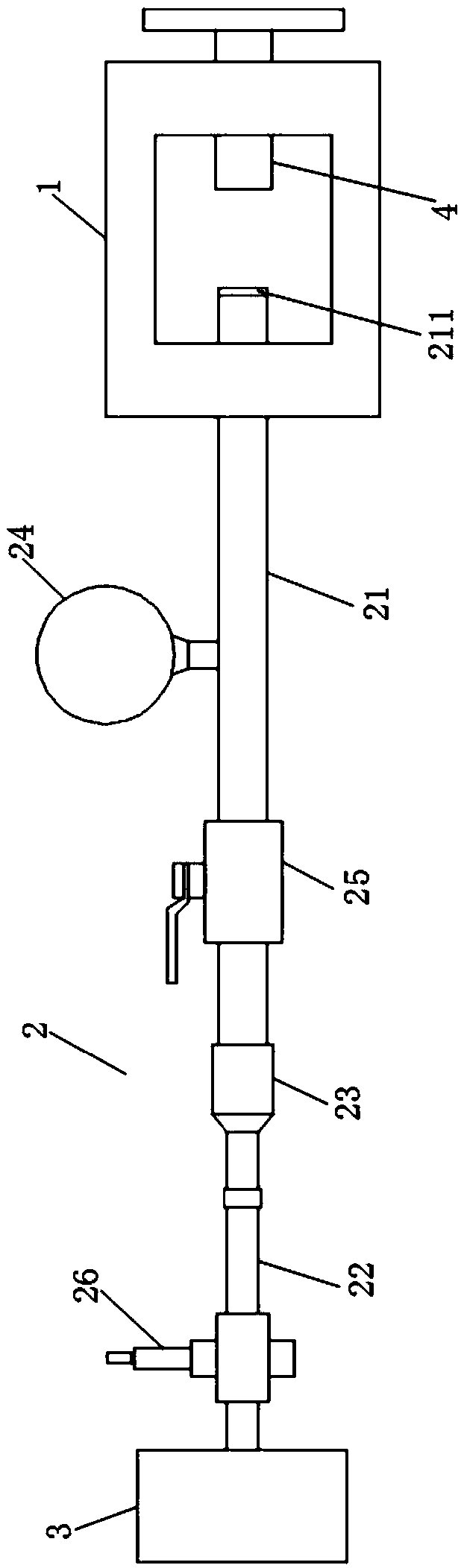

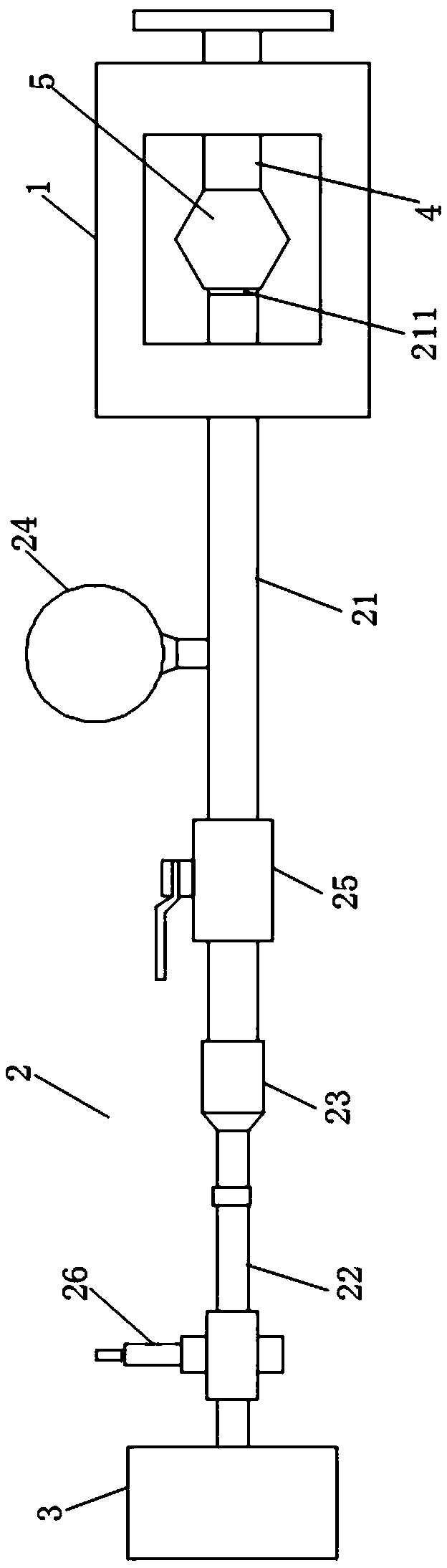

[0029] Embodiment: As shown in the figure, the safety discharge tool for ball valves below DN100 for natural gas pipelines in this embodiment includes a positioning frame 1 and a safety detection discharge pipe group 2;

[0030] The above-mentioned safety detection and discharge pipe group 2 is used to safely discharge the gas discharged from the sewage outlet of the sewage valve. container 3;

[0031] The other end of the above-mentioned positioning frame 1 is equipped with a positioning head 4 extending into its interior, and the above-mentioned positioning head 4 can move closer to or away from the air inlet end of the above-mentioned safety detection and discharge pipe group 2 relative to the above-mentioned positioning frame 1;

[0032] The sewage nozzle 5 of the ball valve is clamped between the air inlet end of the safety detection and discharge pipe group 2 and the positioning head 4, and the sewage outlet of the sewage nozzle 5 is docked with the air inlet end and com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com