Multi-station turntable device for superconducting heat pipe production

A super heat pipe, multi-station technology, applied in applications, household appliances, manufacturing tools, etc., can solve the problems of incomplete processing, high production cost of super heat pipes, product scrap quality, etc., to save production space and cost. , the effect of improving production safety, improving production efficiency and production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

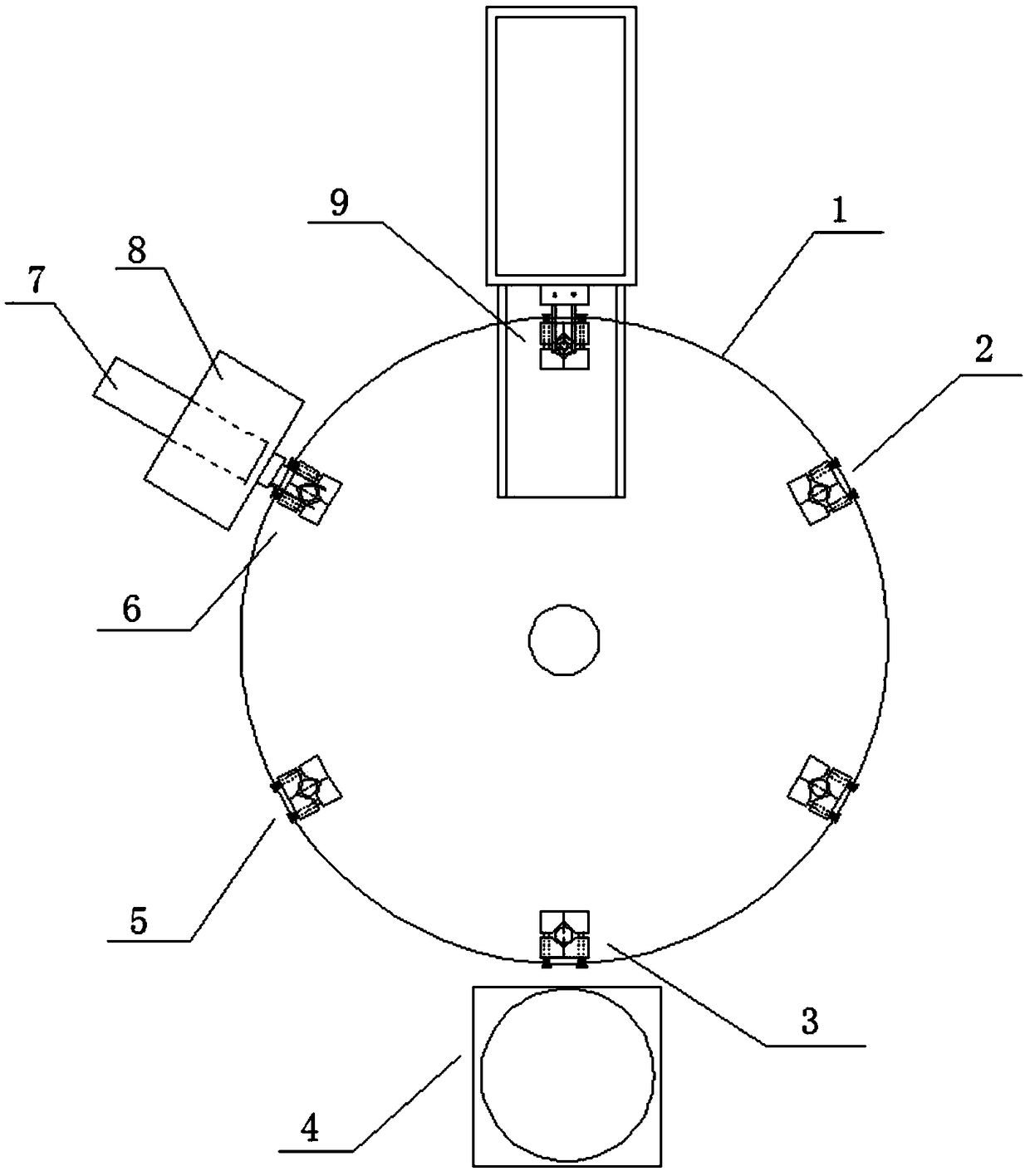

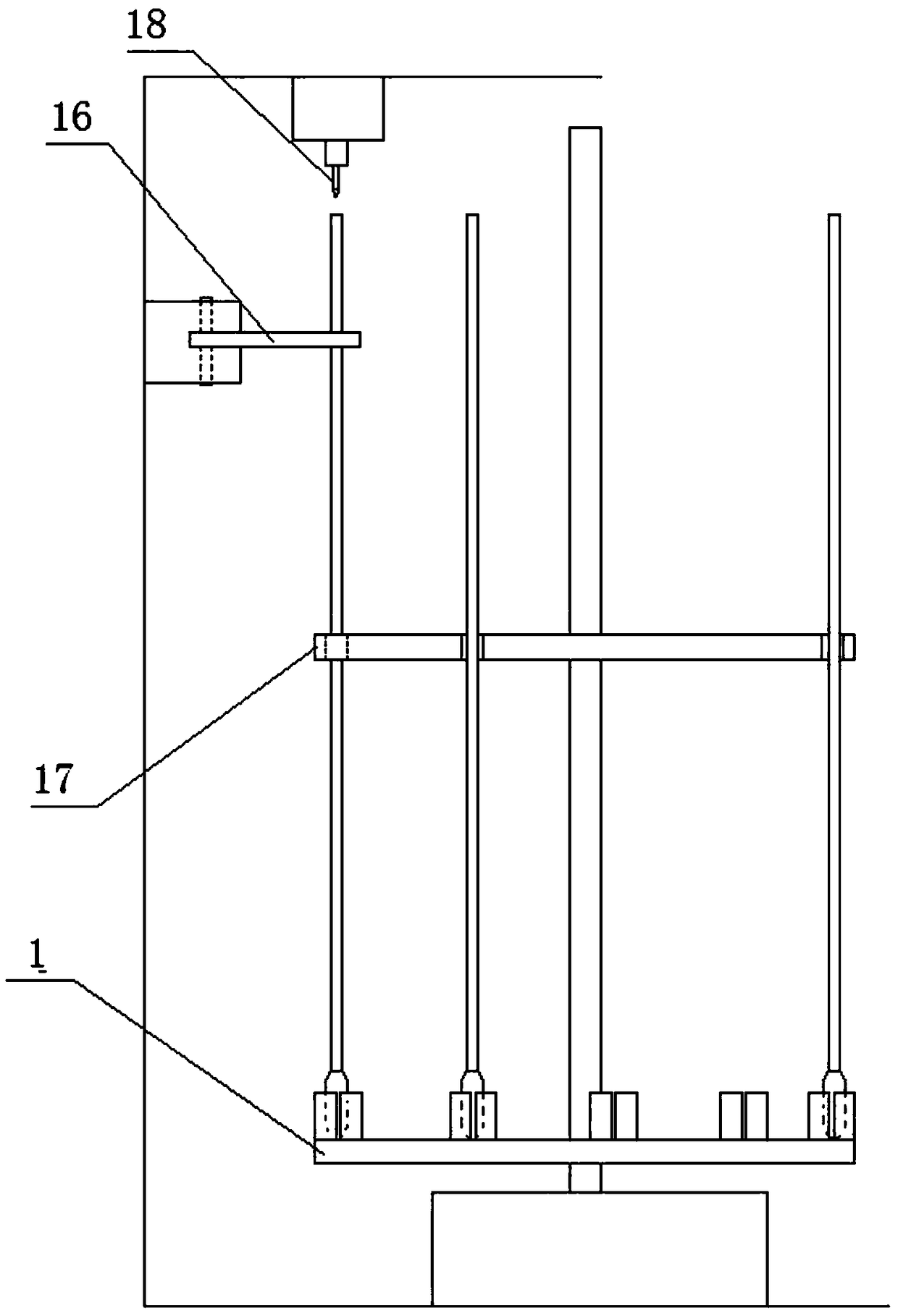

[0018] Embodiment 1, with reference to Figure 1-6 , a multi-station turntable device for producing superconducting heat pipes, including a bracket and a multi-station turntable 1, the multi-station turntable 1 is provided with a tube body fixing frame 17 for fixing the superconducting heat pipe body, along the multi-station The circumferential direction of the turntable 1 is provided with a condensing head conveying station 3, an intubation station 5, a welding station 6, a liquid injection station 9 and a discharge station 2, and a multi-station turntable opposite to each station The condensing head clamping mechanism with the opening facing upwards is installed on 1, the condensing head conveying device is installed at the condensing head conveying station 3, the high-frequency welding machine is installed at the welding station 6, and the drive high-frequency welding is installed on the bracket The first pushing mechanism that the machine reciprocates towards the center of...

Embodiment 2

[0020] Embodiment 2, the multi-station turntable device for producing superconducting heat pipes described in embodiment 1, the condensing head clamping mechanism includes two clamping blocks arranged side by side along the radial direction of the multi-station turntable, wherein One is a fixed clamping block 12, and the other is a movable clamping block 10. The mating surface of the fixed clamping block 12 and the movable clamping block 10 is provided with grooves with openings opposite to each other. The grooves on the two clamping blocks The clamping port 14 of the condensation head of the solar heat pipe is formed, and a guide mechanism for guiding the movable clamping block to move closer to the fixed clamping block is provided between the movable clamping block 10 and the fixed clamping block 12 .

Embodiment 3

[0021] Embodiment 3, the multi-station turntable device for producing superconducting heat pipes described in Embodiments 1 and 2, the guide mechanism includes a guide rod 11 arranged on the movable clamping block 10, and a fixed clamping block 12 There is a guide hole matched with the guide rod, and the guide rod 11 at the outer end of the fixed clamping block 12 is equipped with a return spring 13 for driving the movable clamping block 10 to move closer to the fixed clamping block 12, and there are 3 conveying stations for the condensing head There is a push cylinder for supporting the guide rod 11 to open the clamping port, and the push cylinder is mounted on the support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com