Flame axial propagation velocity measurement method based on flame self-luminous property

A technology of propagation velocity and measurement method, which is applied in the direction of devices using optical methods, can solve the problems of low time resolution and insufficient precision, and achieve the effect of improving time resolution and eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

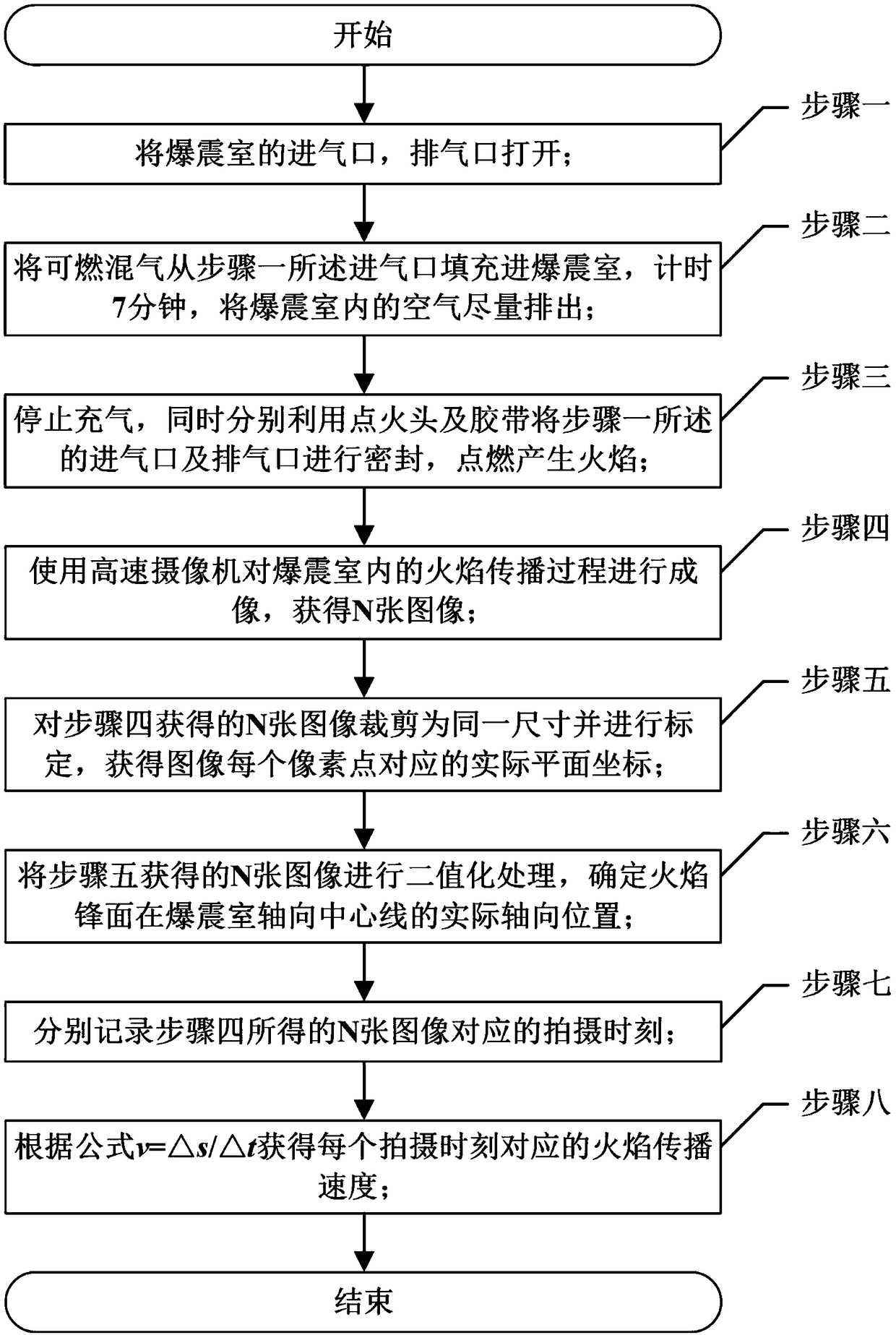

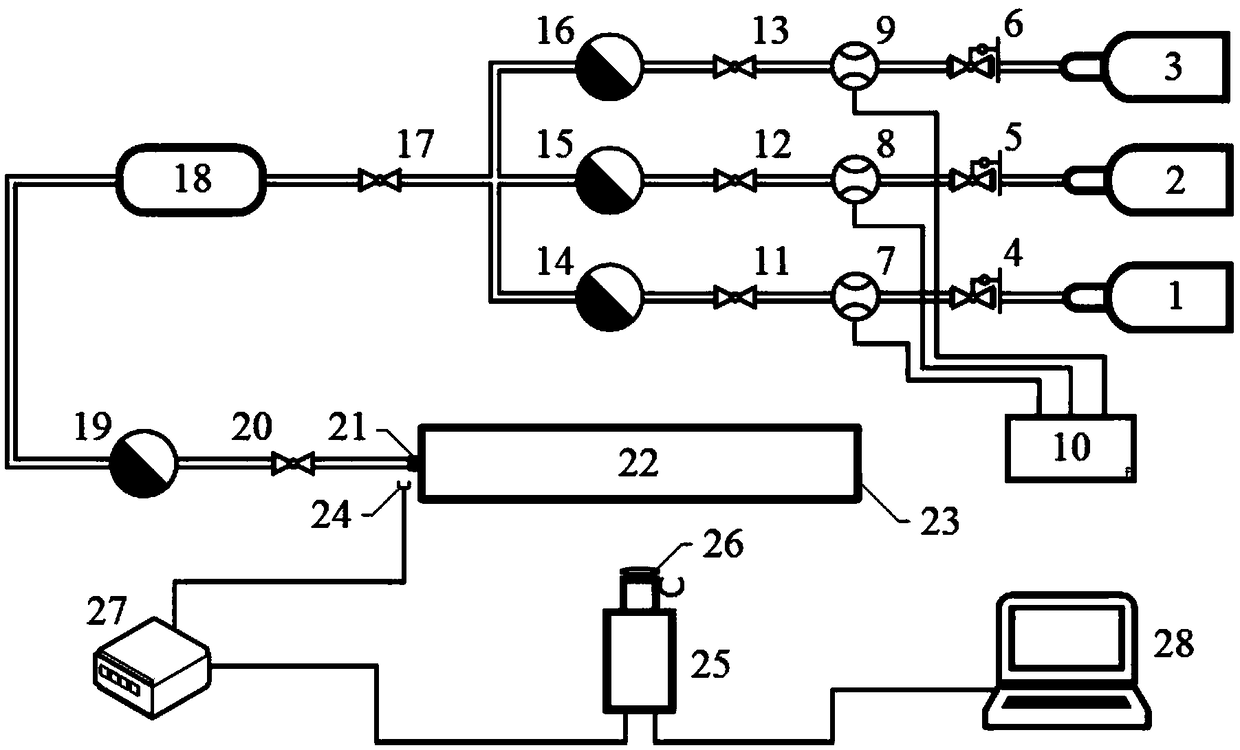

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] figure 1 It is a concrete step in the implementation process of the present invention, and it is realized by the following steps successively:

[0029] Step 1. Open the air inlet and exhaust port of the detonation chamber;

[0030] Step 2: Fill the combustible gas mixture into the detonation chamber from the air inlet described in step 1, time it for 7 minutes, and exhaust the air in the detonation chamber as much as possible;

[0031] Step 3. While stopping the inflation, use the ignition head and tape to seal the air inlet and exhaust port described in step 1 respectively, and ignite to generate flame;

[0032] Step 4, using a high-speed camera to image the flame propagation process in the detonation chamber to obtain N images;

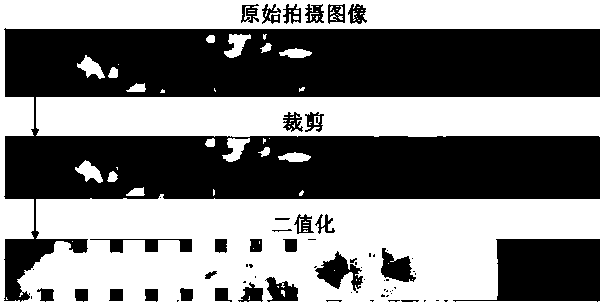

[0033] Step 5. Crop the N images obtained in step 4 to the same size and calibrate them to obtain the actual plane coor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com