A method for on-line soft measurement of coal-fired carbon oxidation factor of pow generation boiler

A technology for carbon oxidation factor and power generation boiler, which is applied in the environmental field and can solve the problems of unfavorable carbon dioxide emissions, greenhouse gas emissions emissions errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

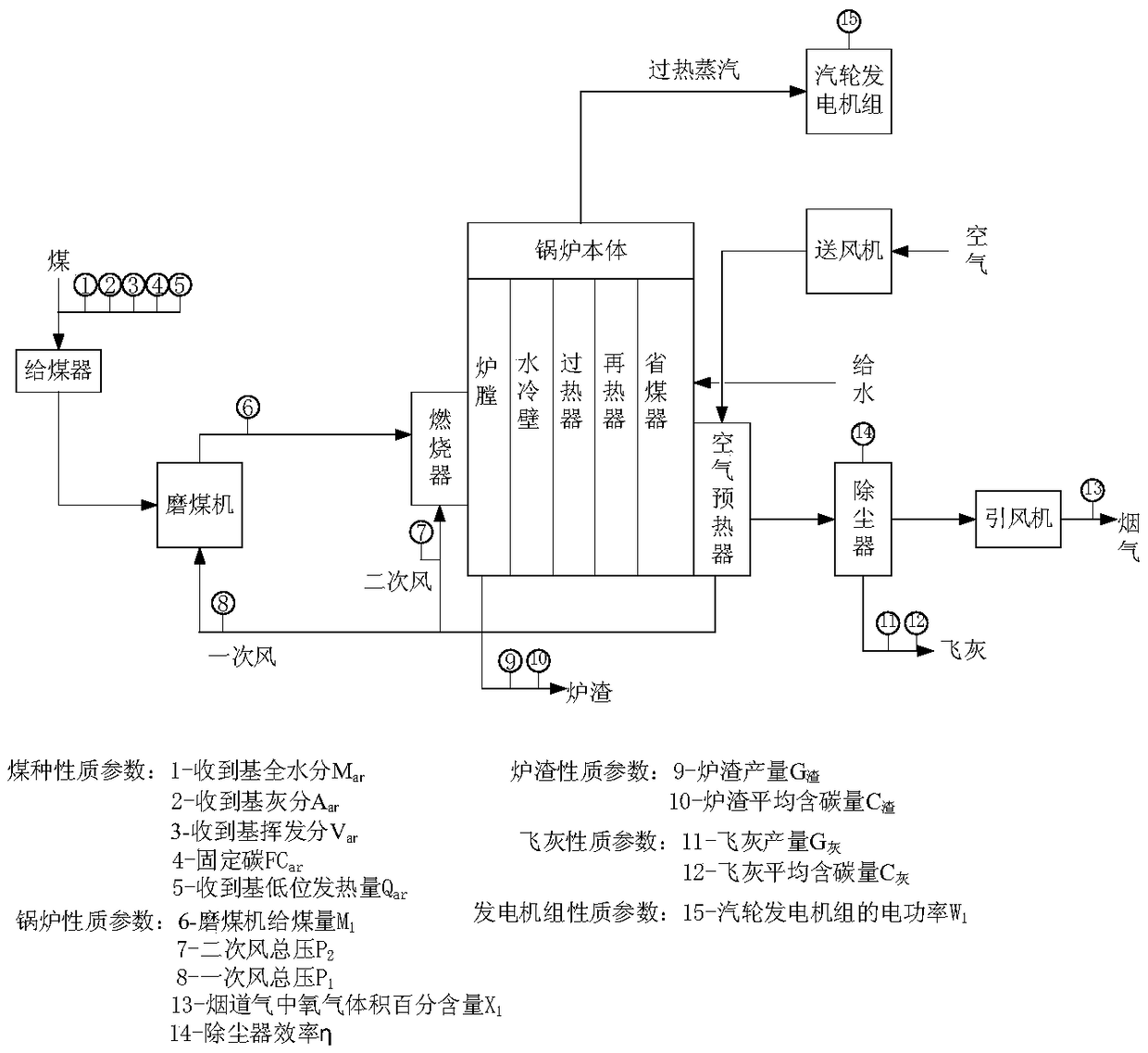

[0110] The present invention will be further described below in conjunction with the accompanying drawings.

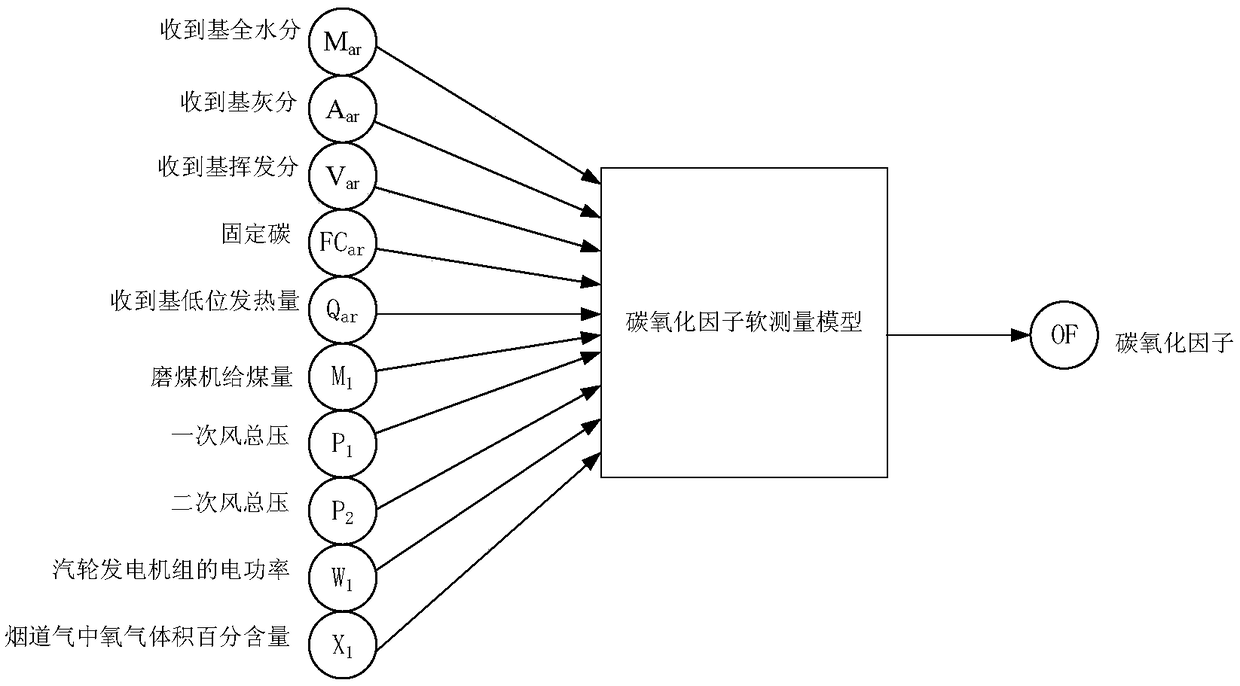

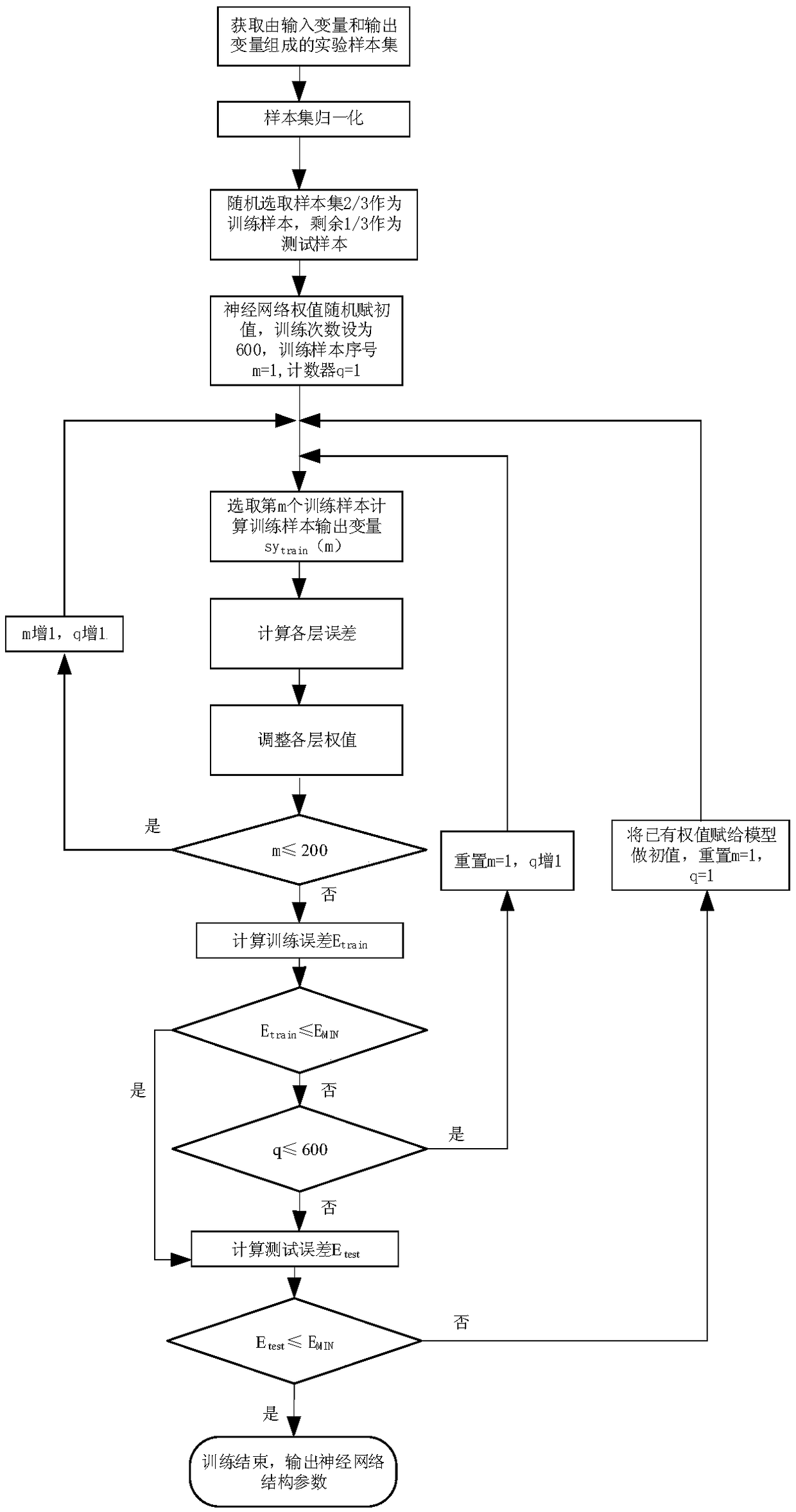

[0111] refer to Figure 1 ~ Figure 3 , an online soft measurement method for coal-fired carbon oxidation factor of a power generation boiler, comprising the following steps:

[0112] Step 1: Select the measurement points of the input variables and output variables of the soft sensor model in the power boiler measurement system, and construct the experimental sample data;

[0113] attached figure 1 It is a common flow chart of a power generating boiler and a description of the positions of relevant measuring points in the present invention. The measurement points shown in the figure are used to obtain the required experimental data of the soft sensor model in the present invention, and 15 measurement points are divided into 5 categories:

[0114] The first category is coal-fired coal type property parameters, including measurement point 1-received base moisture M ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com