Lanthanum iron silicon-based magnetic refrigeration material and preparation method thereof

A magnetic refrigeration material, iron-silicon technology, applied in the fields of magnetic materials, inorganic material magnetism, inductance/transformer/magnet manufacturing, etc., can solve the problem that the half-height and width of entropy change is not large enough, increase the cost of material preparation and processing, and affect the operation of refrigerators. Stability and other issues, to achieve the effect of wide entropy change half-height width, large entropy change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

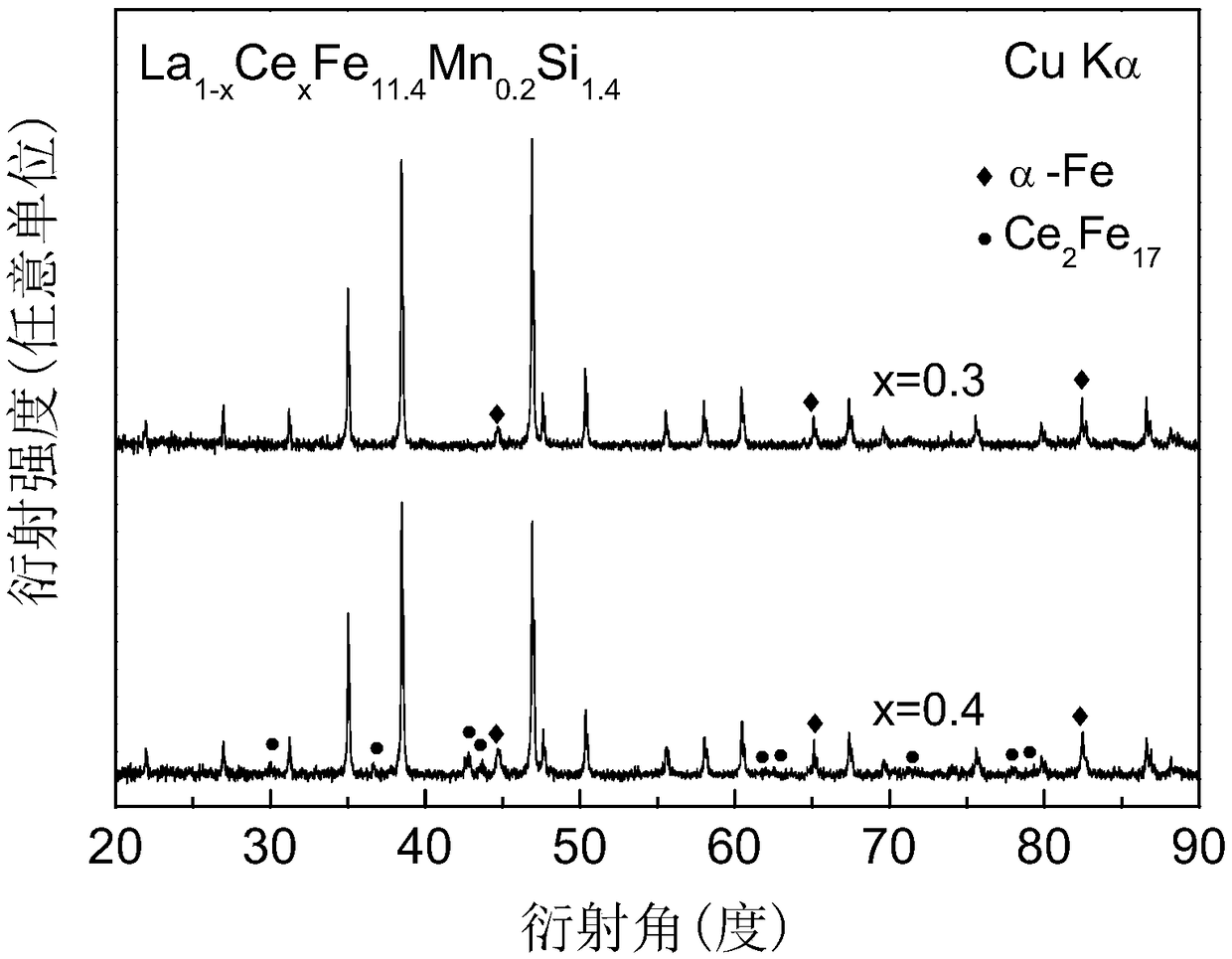

[0039] La 1-x Ce x Fe 11.4 mn 0.2 Si 1.4 (x=0.3 and 0.4) the preparation method of magnetic refrigeration material is as follows:

[0040] (1) Press La 1-x Ce x Fe 11.4 mn 0.2 Si 1.4 (x=0.3 and 0.4) chemical formula batching, will prepare La, Ce, Fe, Mn, Si raw material and pack in the crucible of vacuum induction quick-setting furnace, vacuumize to 5 * 10 -2 Pa, then filled with high-purity argon to 0.05MPa. Turn on the intermediate frequency power supply, heat for a period of time, and start to smelt the metal. After the raw materials are completely melted and kept warm for 5 minutes, the alloy liquid is poured on the rotating copper roller with a speed of 1.7m / s to obtain a quick-setting sheet;

[0041] (2) Break the quick-setting sheet obtained in step (1), then wrap it with a Mo sheet and put it into a quartz tube, and vacuumize it to 1×10 -4 Pa, filled with argon gas of 0.05MPa, and sealed the quartz tube;

[0042] (3) Put the sealed quartz tube in step (2) i...

Embodiment 2

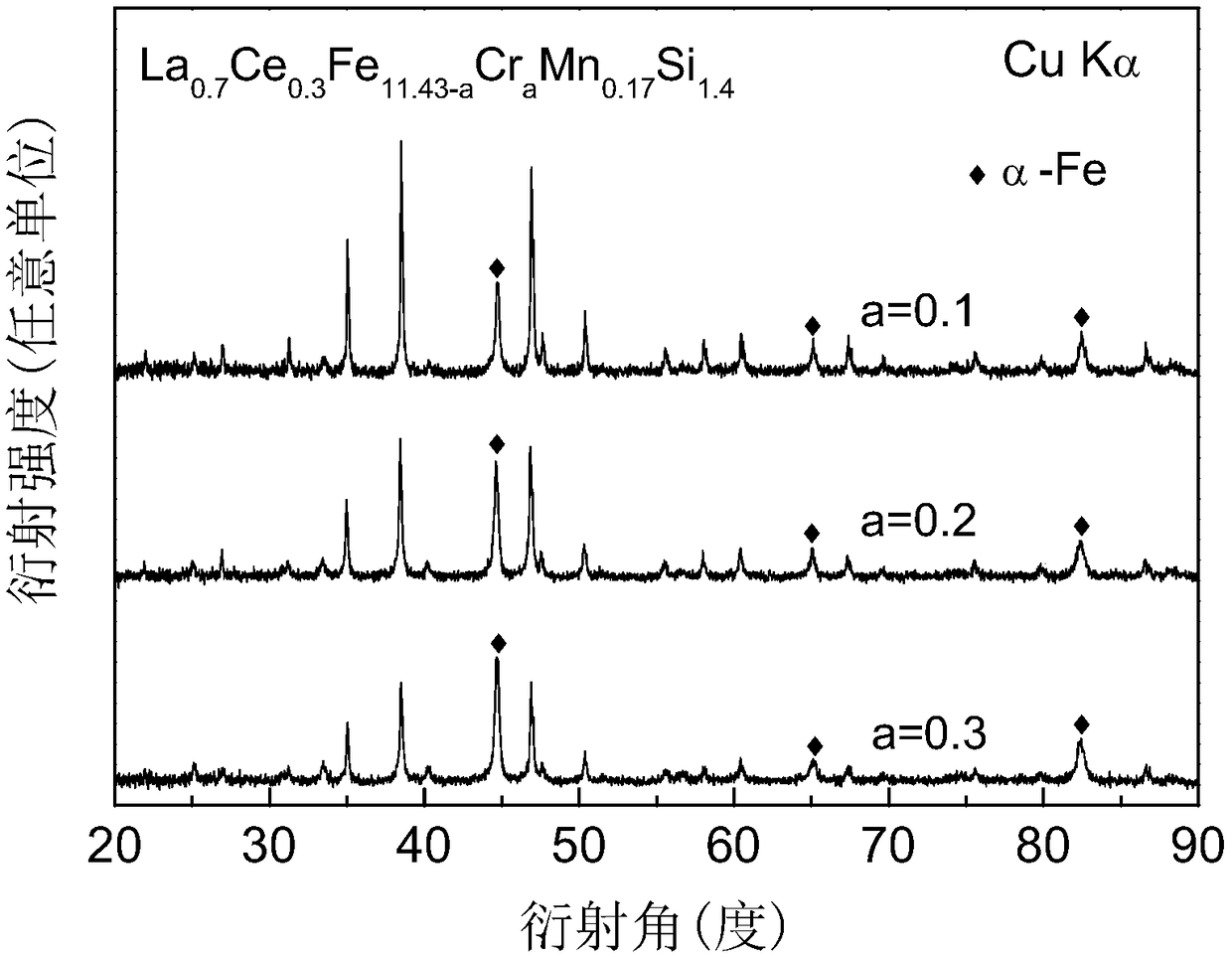

[0046] La 0.7 Ce 0.3 Fe 11.43-a Cr a mn 0.17 Si 1.4 (a=0.1, 0.2 and 0.3) the preparation method of magnetic refrigeration material is as follows:

[0047] (1) Press La 0.7 Ce 0.3 Fe 11.43-a Cr a mn 0.17 Si 1.4 (a=0.1, 0.2 and 0.3) chemical formula ingredients, put the prepared La, Ce, Fe, Cr, Mn, Si raw materials into the crucible of the vacuum induction quick-setting furnace, and evacuate to 5×10 -2 Pa, then filled with high-purity argon to 0.05MPa. Turn on the intermediate frequency power supply, heat for a period of time, and start to smelt the metal. After the raw materials are completely melted and kept warm for 5 minutes, the alloy liquid is poured on the rotating copper roller with a speed of 1.7m / s to obtain a quick-setting sheet;

[0048] (2) Break the quick-setting sheet obtained in step (1), then wrap it with a Mo sheet and put it into a quartz tube, and vacuumize it to 1×10 -4Pa, filled with argon gas of 0.05MPa, and sealed the quartz tube;

[0049] (...

Embodiment 3

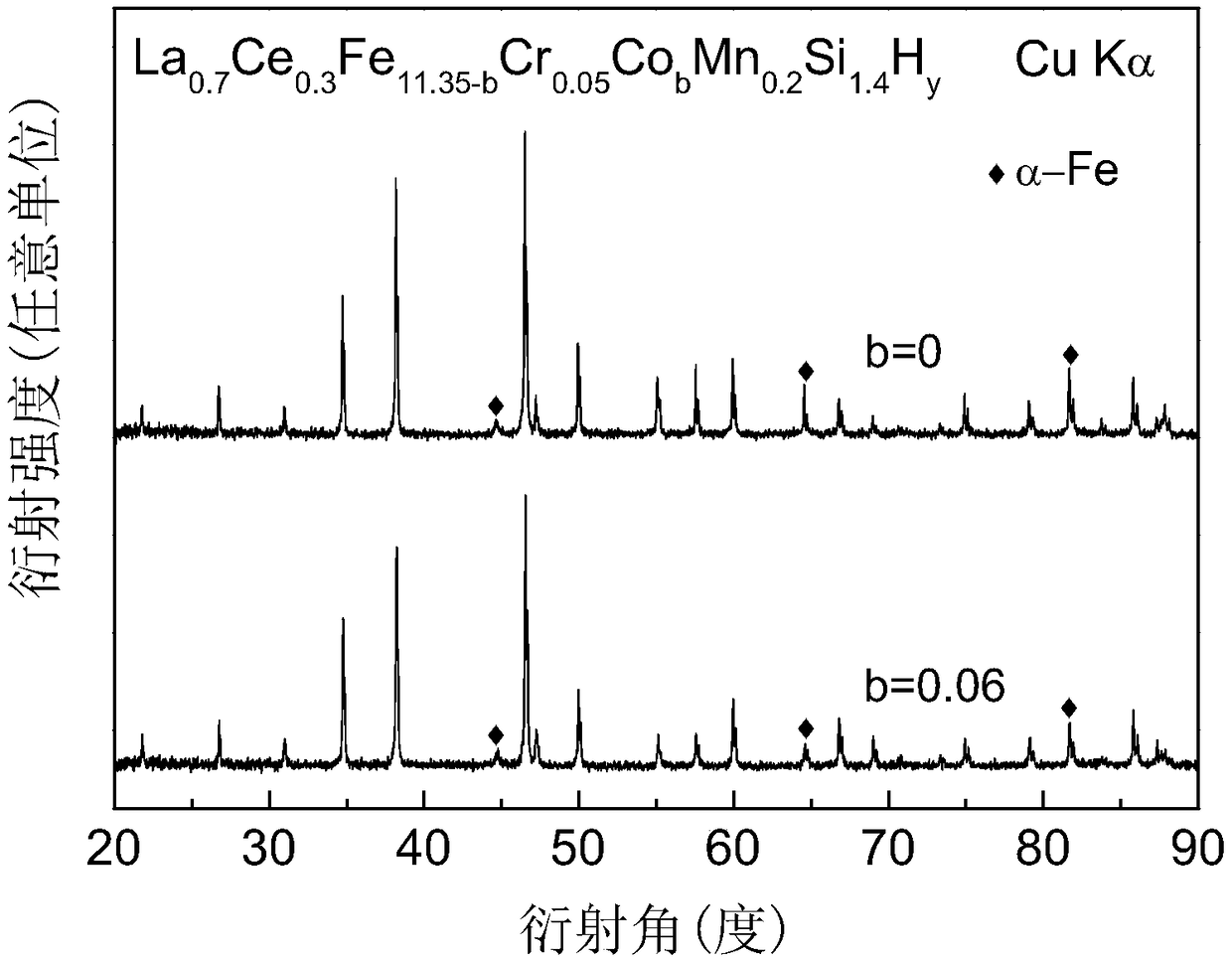

[0053] La 0.7 Ce 0.3 Fe 11.35-b Cr 0.05 co b mn 0.2 Si 1.4 h y The preparation method of the magnetic refrigeration material is as follows:

[0054] (1) Press La 0.7 Ce 0.3 Fe 11.35-b Cr 0.05 co b mn 0.2 Si 1.4 (b=0, 0.06, 0.1, 0.15, and 0.2) Chemical formula ingredients, put the prepared La, Ce, Fe, Cr, Co, Mn, Si raw materials into the crucible of the vacuum induction solidification furnace, and evacuate to 5×10 -2 Pa, then filled with high-purity argon to 0.05MPa. Turn on the intermediate frequency power supply, heat for a period of time, and start to smelt the metal. After the raw materials are completely melted and kept warm for 5 minutes, the alloy liquid is poured on the rotating copper roller with a speed of 1.7m / s to obtain a quick-setting sheet;

[0055] (2) Break the quick-setting sheet obtained in step (1), then wrap it with a Mo sheet and put it into a quartz tube, and vacuumize it to 1×10 -4 Pa, filled with argon gas of 0.05MPa, and sealed the qua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com