Internal spinning device

An internal spinning and equipment technology, applied in the field of internal spinning forming, can solve the problems of too long rotor arm, large friction force, and inability to demold the workpiece, and achieve the effect of satisfying precise control and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with specific examples and accompanying drawings.

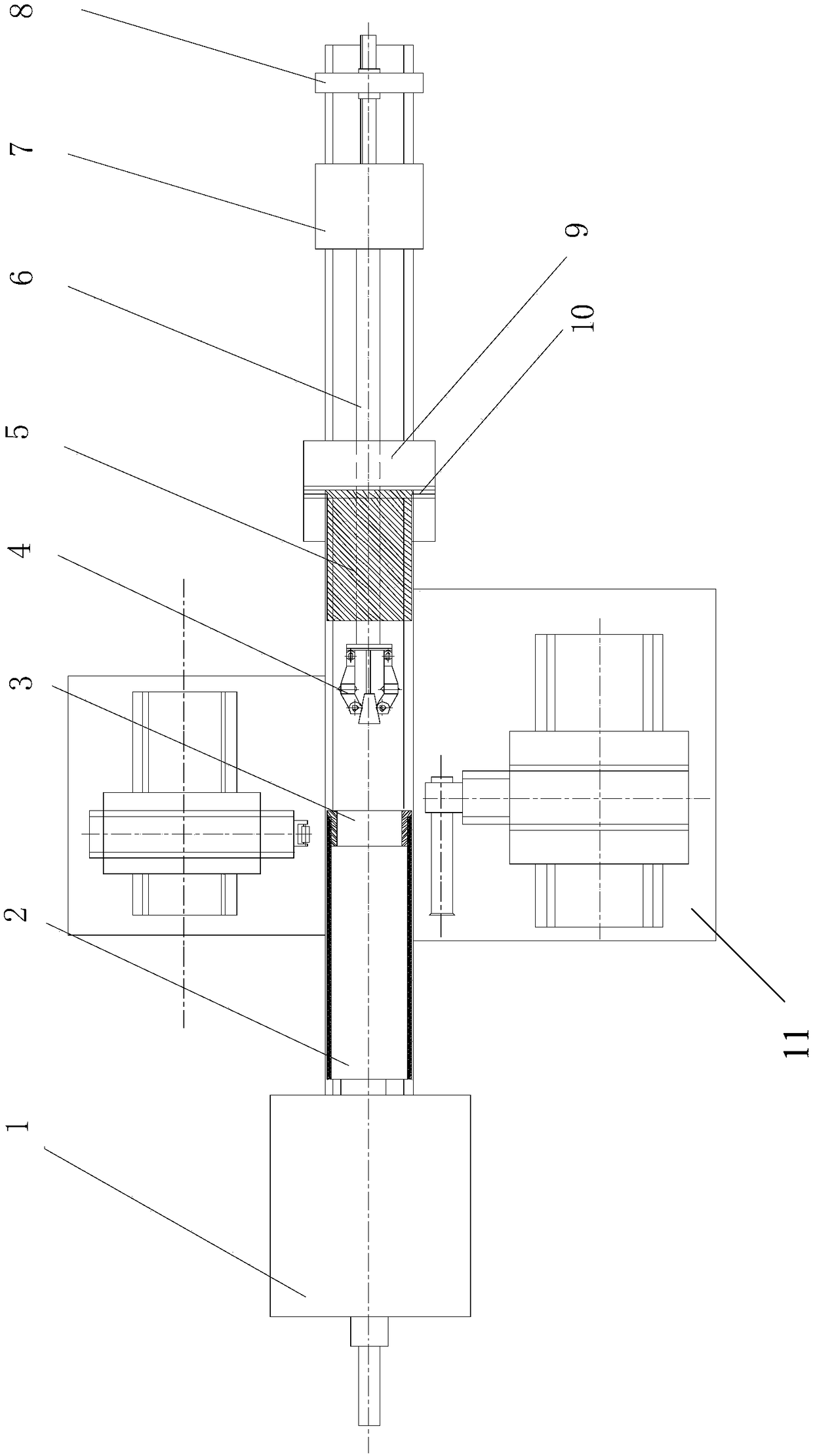

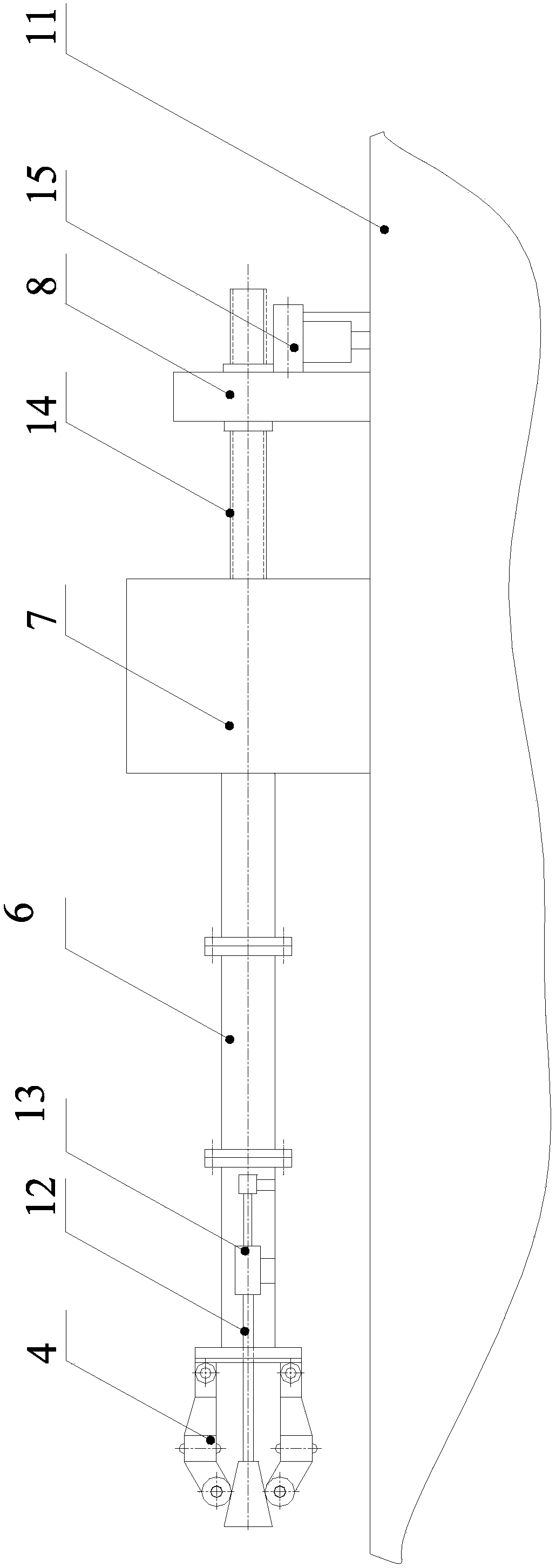

[0027] Spinning equipment such as figure 1 As shown, it includes the spindle box 1, the mold transmission cylinder 2, the rotary wheel mechanism, the traction mechanism 9, the binder ring 10 and the CNC machine bed 11, the mold transmission cylinder 2 is installed on the CNC machine tool spindle, and the mold 3 is installed on the mold transmission cylinder 2. The front end of the inner cavity, the wheel mechanism and the traction mechanism 9 are installed on the bed 11 of the CNC machine tool.

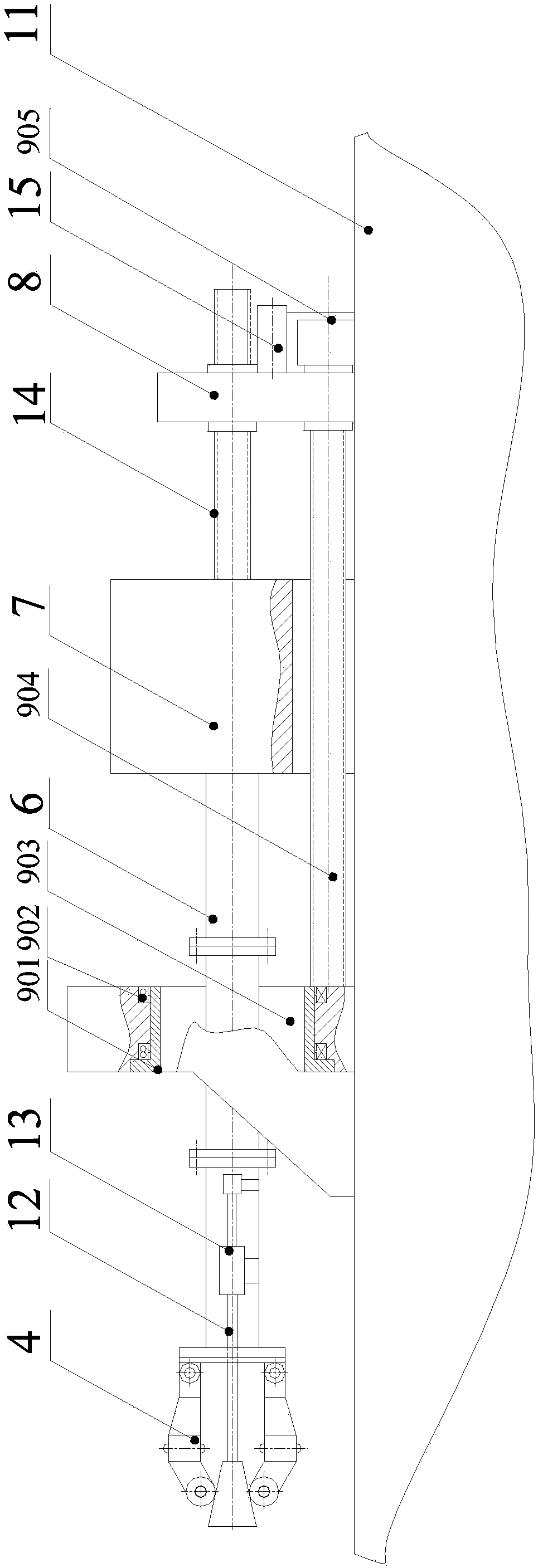

[0028] traction mechanism 9 such as image 3 As shown, it includes a traction mechanism rotor 901, a traction mechanism rotor bearing 902, a traction mechanism seat 903, a traction mechanism axial feed screw 904 and a traction mechanism axial feed drive motor 905. The traction mechanism rotor 901 passes through the traction mechanism The rotating body be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com