Drilling device for communication connector

A drilling device and connector technology, applied in positioning device, clamping, supporting and other directions, can solve the problems of easy deviation of compression nut positioning, inability to continuously process production, low production efficiency, etc., to improve the quality of processed products, Simple structure and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

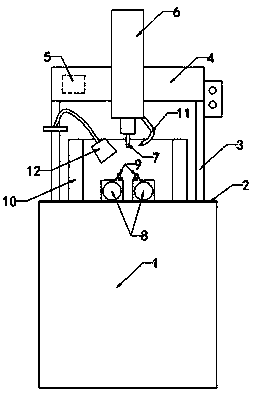

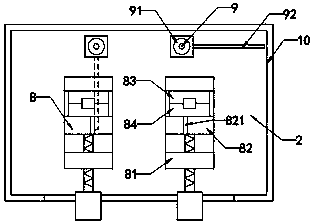

[0013] Depend on figure 1 , figure 2 Known, it is a communication connector drilling device, including a frame 1, a workbench 2 is provided on the frame 1, two support plates 3 are provided on the workbench 2, and beams are connected between the support plates 3 4. The beam 4 is provided with a driving device I5, and a laterally moving arm 6 is connected to the beam 4. The driving device I5 controls the laterally moving arm 6 to move laterally; Drilling tool 7; said workbench 2 is also provided with two symmetrical clamping mechanisms 8 below the lateral movement arm 6, and a workpiece positioning inspection mechanism 9 is provided at the top of clamping mechanisms 8; said clamping mechanisms 8 consists of a base 81, a clamping block adjustment part 82 set on the base 81, a clamping block I 83 and a clamping block II 84 placed on the base 81, and the clamping block I 83 and clamping block II 84 are provided with corresponding workpieces. The mounting holes allow the clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com