Sunflower seed shelling packaging machine

A technology of encapsulating machine and melon seed shell, applied in the field of melon seed shelling encapsulation machine, can solve the problems of high labor intensity, inability to meet mass production and processing, low work efficiency, etc., to achieve reduced labor intensity, good shelling effect, and labor reduction. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

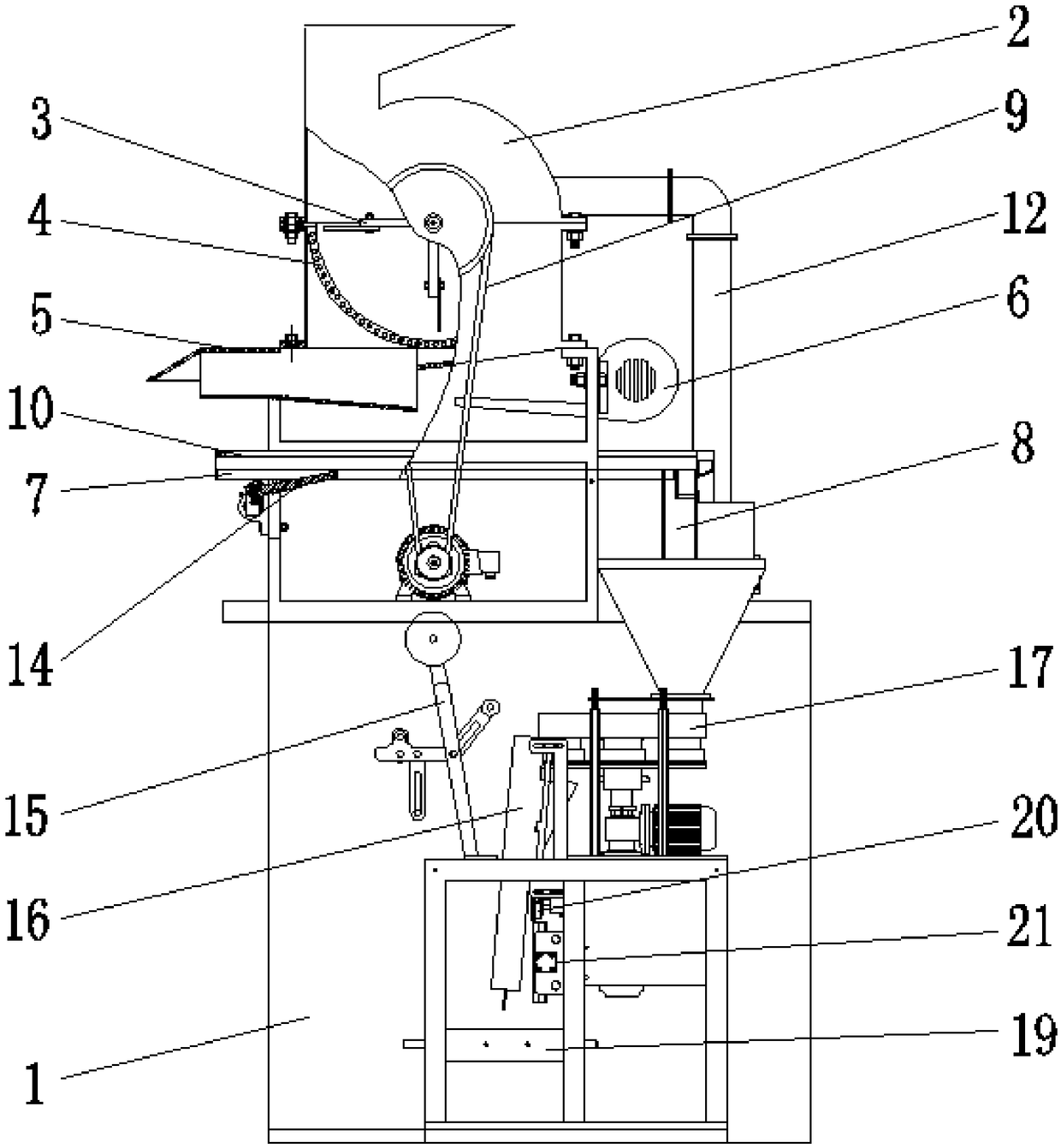

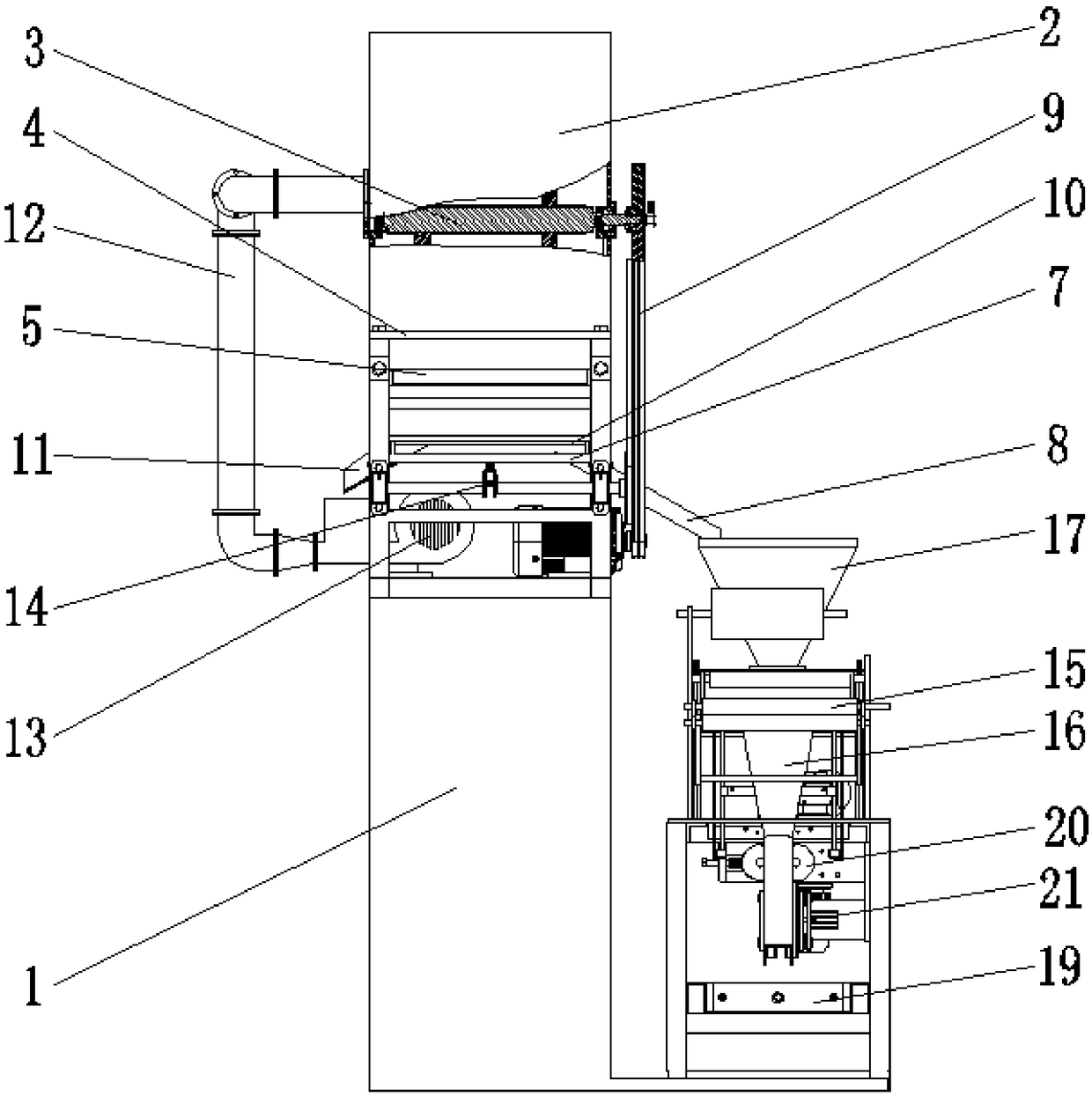

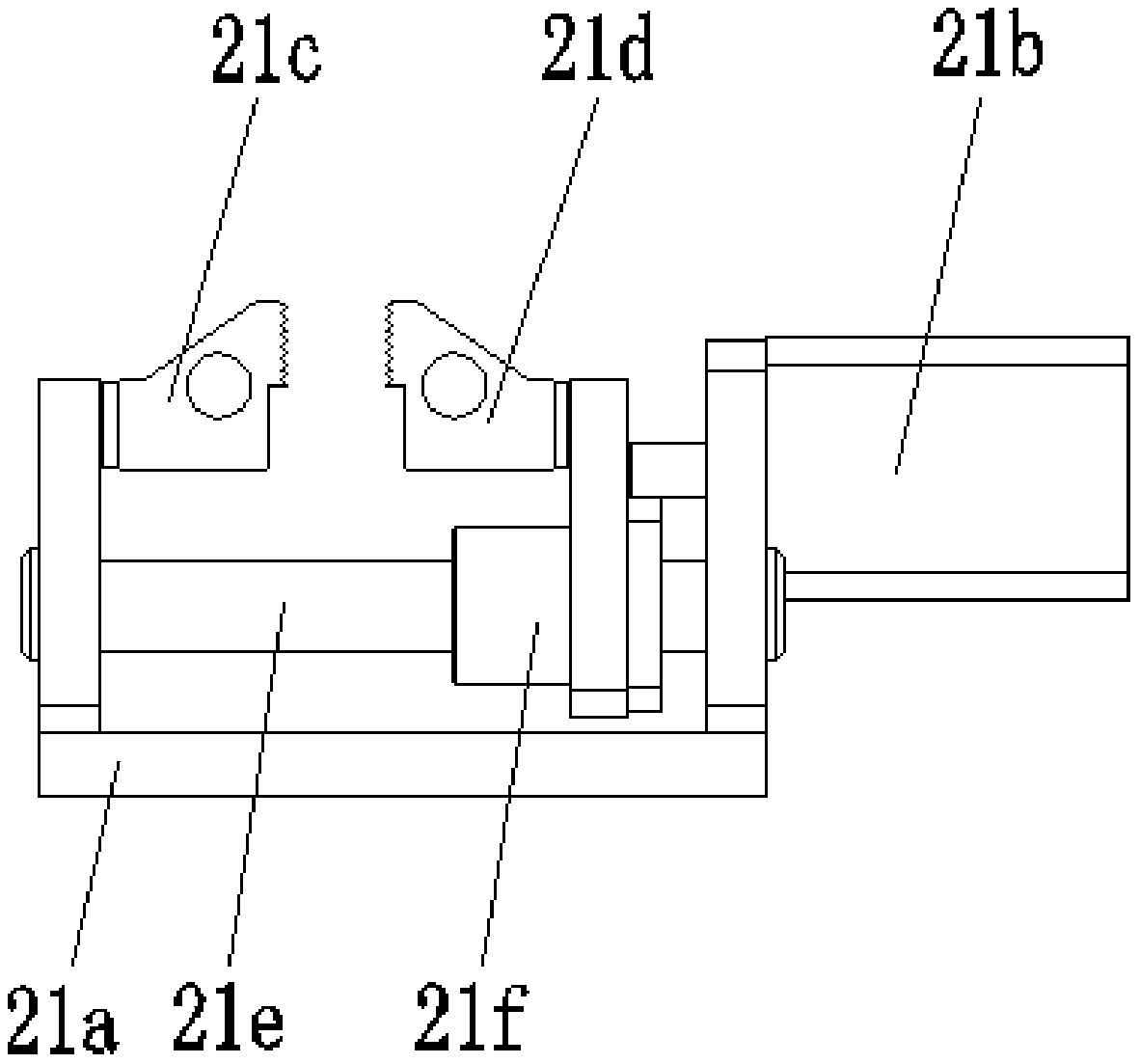

[0034] refer to Figure 1-9 , a melon seed shelling and encapsulating machine of the present invention comprises a frame 1, and a shelling device and a packaging device are integrated on the frame 1, wherein the shelling device is used for shelling melon seeds, and the encapsulating device is used for shelling melon seeds Packing, the shelling device includes a box body 2 and a scraper assembly 3 and a half grid cage 4 located in the box body 2. The box body 2 is composed of two parts, which is convenient for disassembly and assembly. The half grid cage 4 is a grid with a through groove. The grid plate and the scraper assembly 3 are rotatably mounted on the top of the half grid cage 4. The scraper assembly 3 and the half grid cage 4 are rotatably matched to shell the melon seeds. The melon seed shell collecting box 5 that inwardly inclines ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com