Denitrification and COD removal treatment process for high-calcium and high-salt sewage

A high-salt sewage and treatment process technology, applied in water/sewage treatment, biological water/sewage treatment, water/sewage treatment equipment, etc., can solve the problem of affecting the normal function of microorganisms, long activated sludge cycle, biofilm loss, etc. problems, to avoid system fouling, improve COD removal rate, and shorten the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

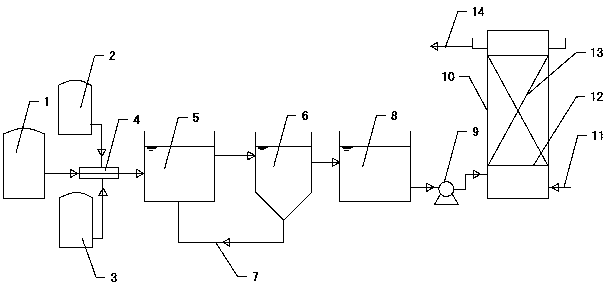

Method used

Image

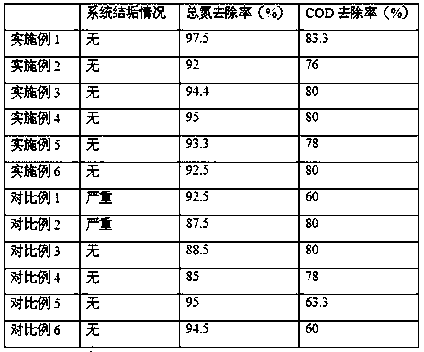

Examples

Embodiment 1

[0036]High-calcium and high-salt sewage influent indicators: total nitrogen 200mg / L, ammonia nitrogen 20mg / L, COD 150mg / L, conductivity 35000μs / cm, calcium content 4000mg / L.

[0037] Sludge domestication process: The activated sludge from the petrochemical sewage treatment plant was selected as the inoculum for sludge domestication, and the domestication period was 30 days.

[0038] 1) Influent, high-calcium and high-salt sewage, acetic acid and inorganic acid are mixed evenly through the pipeline mixer and then enter the denitrification tank. Among them, the concentration of acetic acid is 500 mg / L, and the concentration of sulfuric acid is 40 mg / L;

[0039] 2) Denitrification, the hydraulic retention time of the denitrification tank is 20 hours, the dissolved oxygen concentration is 0.5mg / L, the sludge concentration is 4000mg / L, and the pH is 6.5-7.5. The denitrification bacteria that have been acclimated by the sludge are under the action of the carbon source Carry out deni...

Embodiment 2

[0045] High-calcium and high-salt sewage influent indicators: total nitrogen 100mg / L, ammonia nitrogen 10mg / L, COD 100mg / L, conductivity 25000μs / cm, calcium content 2000mg / L.

[0046] Sludge domestication process: The activated sludge from the petrochemical sewage treatment plant was selected as the inoculum for sludge domestication, and the domestication period was 25 days.

[0047] 1) Influent, high-calcium and high-salt sewage, acetic acid and inorganic acid are mixed evenly through the pipeline mixer and then enter the denitrification tank. Among them, the concentration of acetic acid is 350 mg / L, and the concentration of sulfuric acid is 60 mg / L;

[0048] 2) Denitrification, the hydraulic retention time of the denitrification tank is 15 hours, the dissolved oxygen concentration is 0.5mg / L, the sludge concentration is 4000mg / L, and the pH is 6.5-7.5. The denitrification bacteria that have been domesticated by the sludge are under the action of the carbon source Carry out d...

Embodiment 3

[0054] High-calcium and high-salt sewage influent indicators: total nitrogen 180mg / L, ammonia nitrogen 20mg / L, COD 150mg / L, conductivity 35000μs / cm, calcium content 4000mg / L.

[0055] Sludge domestication process: The activated sludge from the petrochemical sewage treatment plant was selected as the inoculum for sludge domestication, and the domestication period was 28 days.

[0056] 1) Influent, high-calcium and high-salt sewage, acetic acid and inorganic acid are mixed evenly through the pipeline mixer and then enter the denitrification tank. Among them, the dosing concentration of acetic acid is 800mg / L, and the dosing concentration of sulfuric acid is 50 mg / L;

[0057] 2) Denitrification, the hydraulic retention time of the denitrification tank is 20 hours, the dissolved oxygen concentration is 0.5mg / L, the sludge concentration is 4000mg / L, and the pH is 6.5-7.5. The denitrification bacteria that have been acclimated by the sludge are under the action of the carbon source ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap