Washing machine

A washing machine and additive technology, applied in the field of washing machines, can solve the problems of insufficient installation of multi-functional electronic modules, insufficient space in the lower part of a control panel base, easy accumulation of dust and dirt on detergents, etc., and achieves the effects of simple structure, cost saving, and convenience for replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

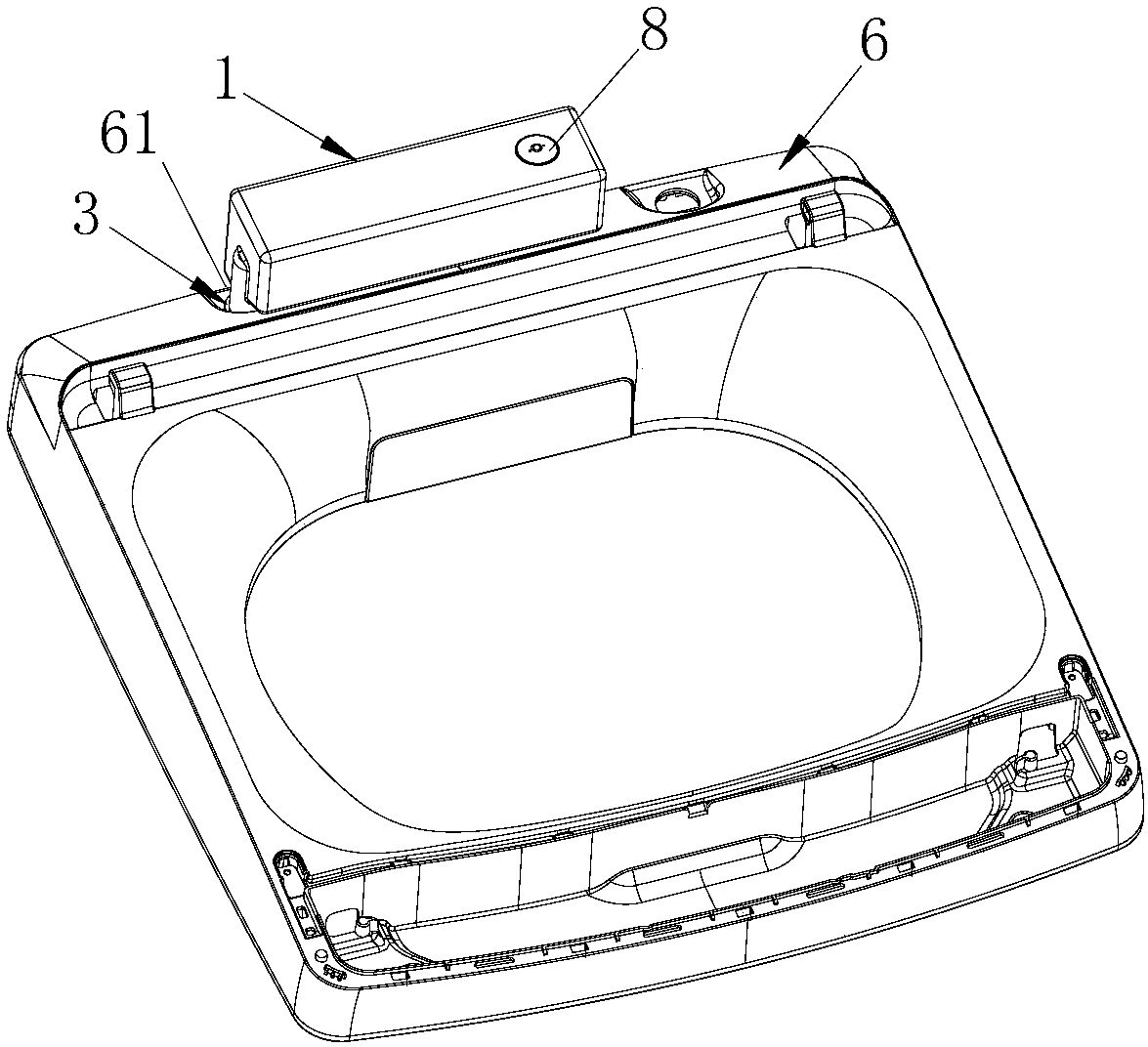

[0063] Such as figure 1 As shown, the washing machine described in this embodiment is a pulsator washing machine, including a control panel seat 6, and the container 1 can be detachably installed above the control panel seat 6 of the washing machine, and can also be installed on the outer wall of the control panel seat. 6 is provided with an interface structure 3 , and a container mounting portion 61 and a positioning portion 62 matching with the container 1 are provided on the upper rear side of the control panel base 6 . Preferably, the container mounting portion 61 is a concave portion provided on the rear surface of the control panel base 6 to be recessed and matched with the container.

[0064] Preferably, the positioning portion 62 is a positioning protrusion provided on the container installation portion, and the container 1 is provided with a positioning groove 11 corresponding to the positioning protrusion.

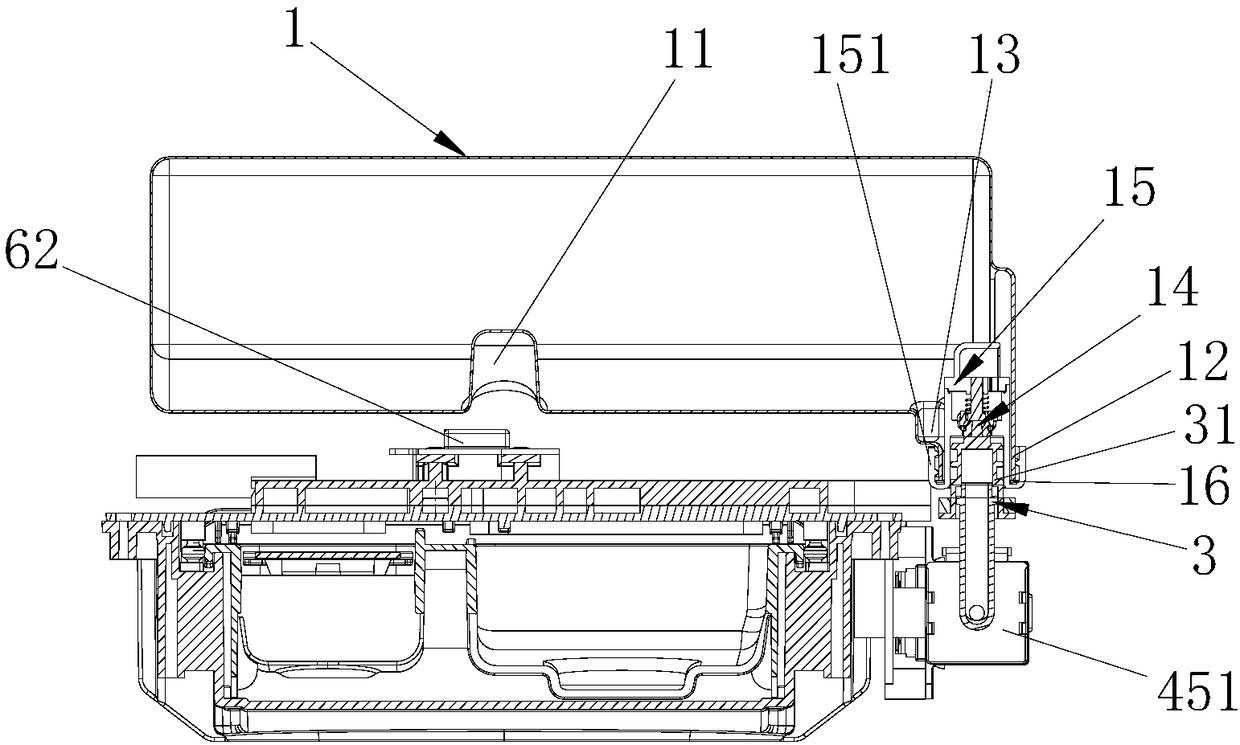

[0065] Such as figure 2 and image 3 As shown, the inte...

Embodiment 2

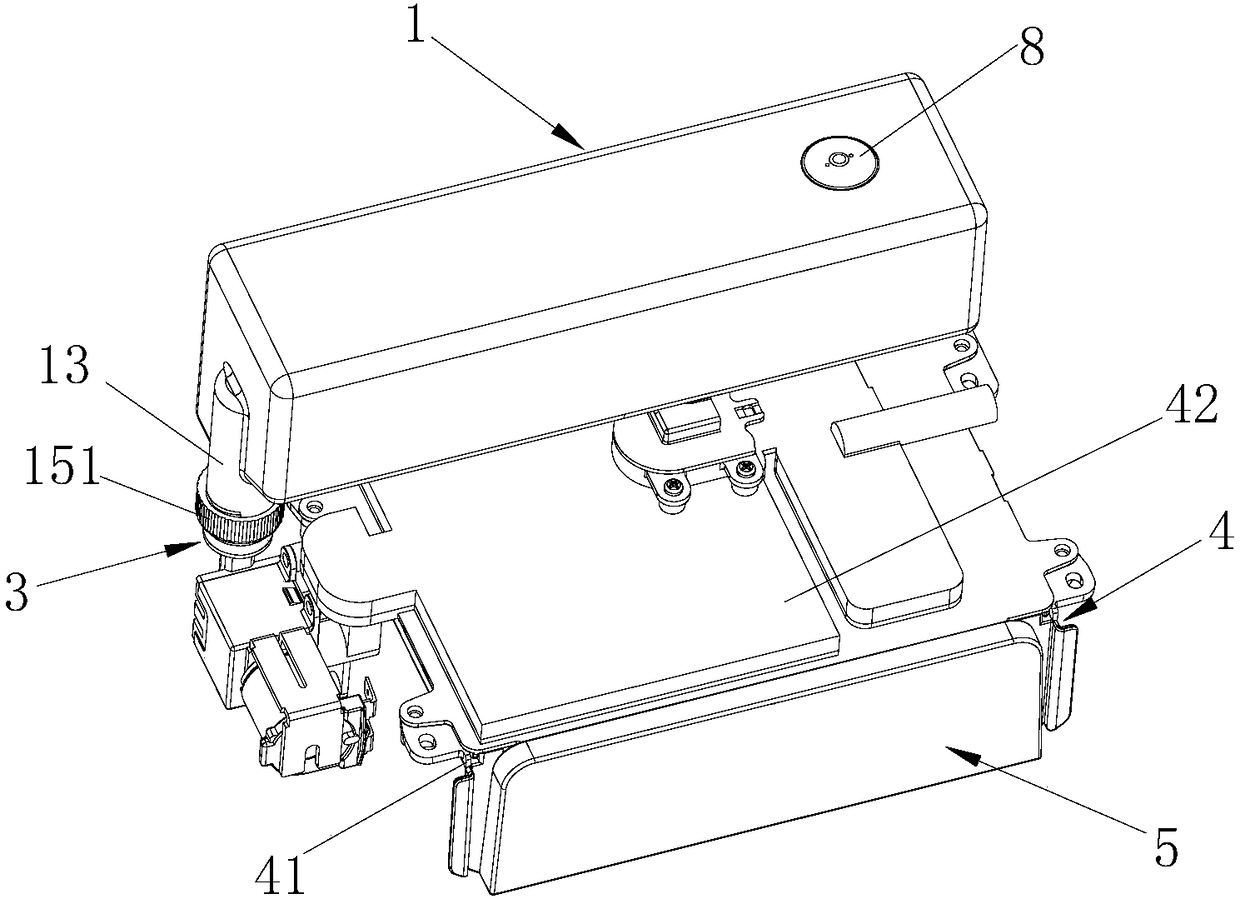

[0067] Such as Figure 4 to Figure 7 As shown, the additive dosing system described in this embodiment includes a first dosing unit and a second dosing unit. The first dosing unit is installed in the control panel base 6 and is a manual dosing unit, including a water tank 4 and a puller set in the water tank 4. The dispensing box 5, the automatic delivery mechanism 2 is located on the tank 4 of the first delivery unit, the second delivery unit is an external delivery unit, including the container 1 for holding the additive, the first delivery unit and the second delivery unit have The common feeding waterway, the additive in the container 1 is led out by the automatic feeding mechanism and dropped into the washing machine from the first feeding unit.

[0068] The water tank 4 includes a body 41 and a waterway integration module 42 installed on the body 41. The waterway integration module 42 is provided with at least one delivery waterway 7 communicating with the distribution b...

Embodiment 3

[0074] Such as Figure 7 As shown, the automatic feeding mechanism 2 of the present invention includes an additive extraction unit 21 and an additive extraction pipeline 22, the additive extraction unit 21 communicates with the injection waterway 7, the liquid inlet end of the additive extraction pipeline 22 communicates with the interface structure 3, and the liquid outlet The end communicates with the additive extraction unit 21.

[0075] Preferably, the additive extraction unit 21 includes a negative pressure forming part arranged in the injection water channel, which is a Venturi tube arranged in the main water inlet 432, and the outlet end of the additive extraction pipeline 22 communicates with the negative pressure forming part, and the additive extraction Then it enters the main water inlet 432 through the negative pressure forming part, then flows into the detergent / washing powder chamber 51 of the distribution box through the water inlet branch 441, and finally flows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com