Thread defect detecting method and device based on linearly polarized light

A technology of linearly polarized light and defect detection, which is applied in the direction of measuring devices, optical devices, and optical testing of defects/defects, can solve problems such as the inability to correctly detect the number of threads, thread length defects, missing thread profile features, etc., to achieve convenience Image processing and analysis, reduction of image processing time, effect of reducing bright spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention, rather than limit the protection scope of the present invention.

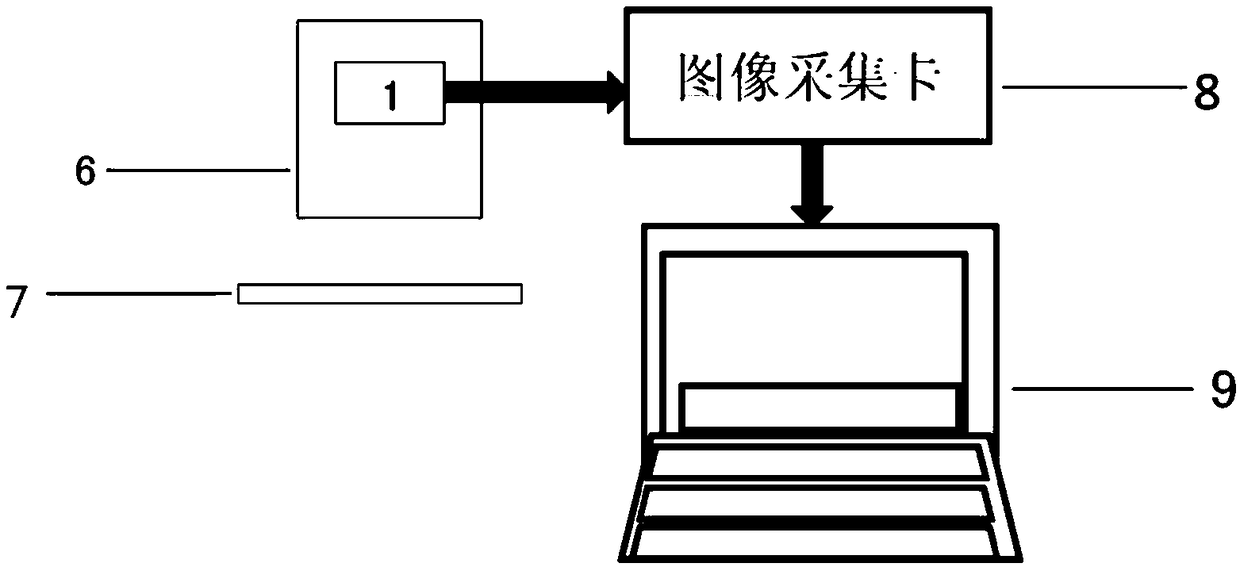

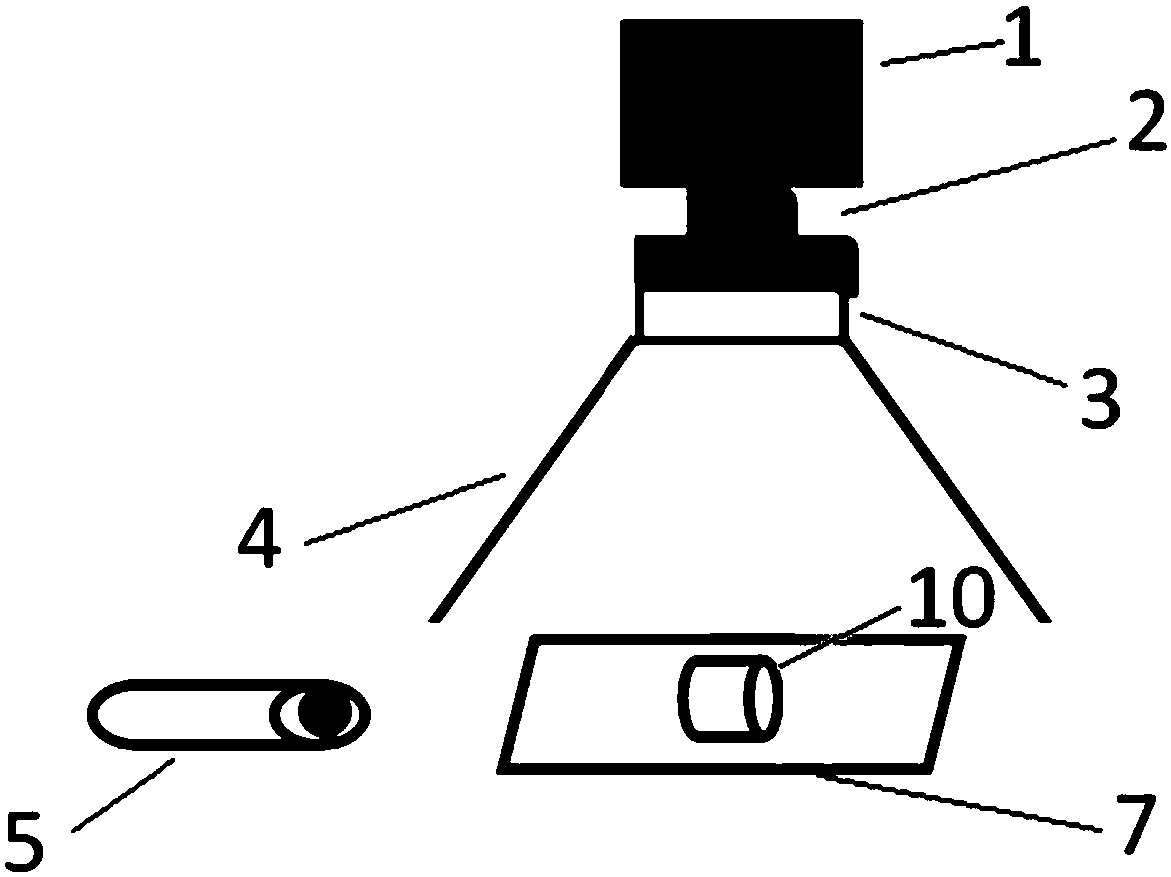

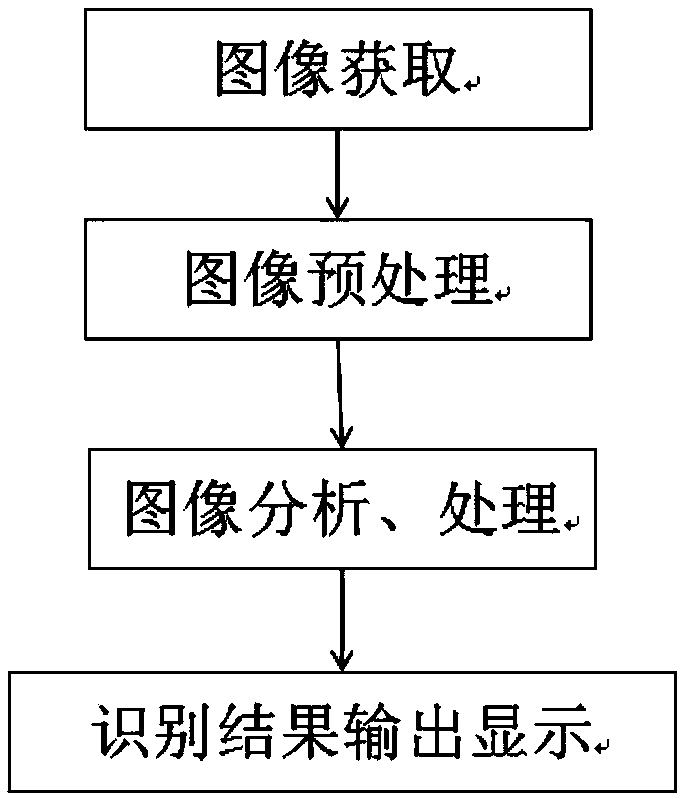

[0031] see figure 1 as well as figure 2 , the present invention proposes a thread defect detection device based on linearly polarized laser, including an area array CCD image sensor 6, a storage platform 7, an image acquisition card 8 and a computer 9; wherein, the area array CCD image sensor 6 includes an area array CCD camera 1 (MTV-1881EX-3, black and white, low illumination, high resolution), manual aperture fixed-focus lens 2, anti-disturbance filter 3, hood 4 and laser linearly polarized light source 5; manual aperture fixed-focus lens 2 The imaging specification is consistent with the target surface specification of the area array CCD camera 1, and the manual aperture fixed-focus lens 2 and the area array CCD camera 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com