Lens system

A lens system and lens technology, applied in the field of lens systems, can solve the problems of complex installation and processing, not meeting the aesthetic requirements of consumers, etc., and achieve the effects of easy processing and installation, improving user experience, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

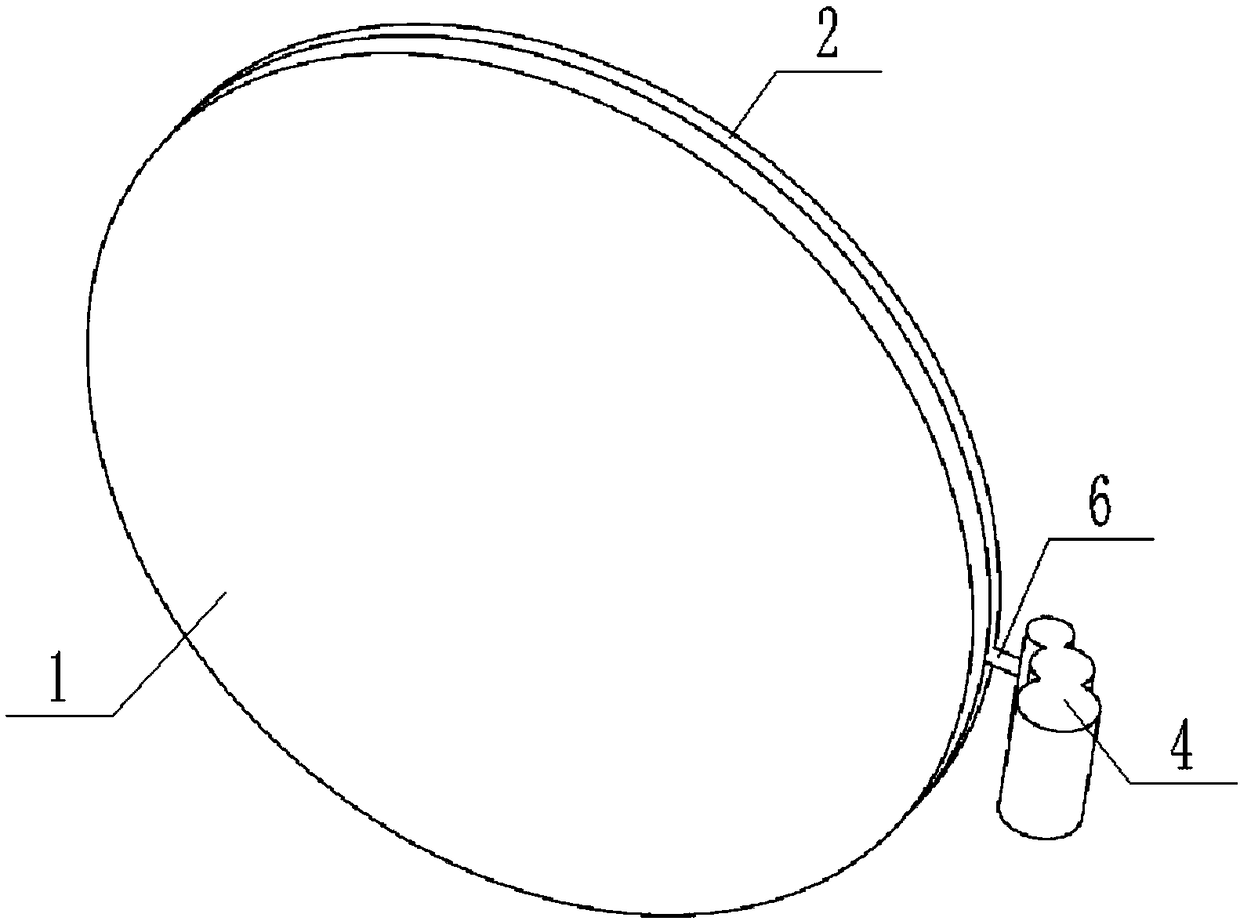

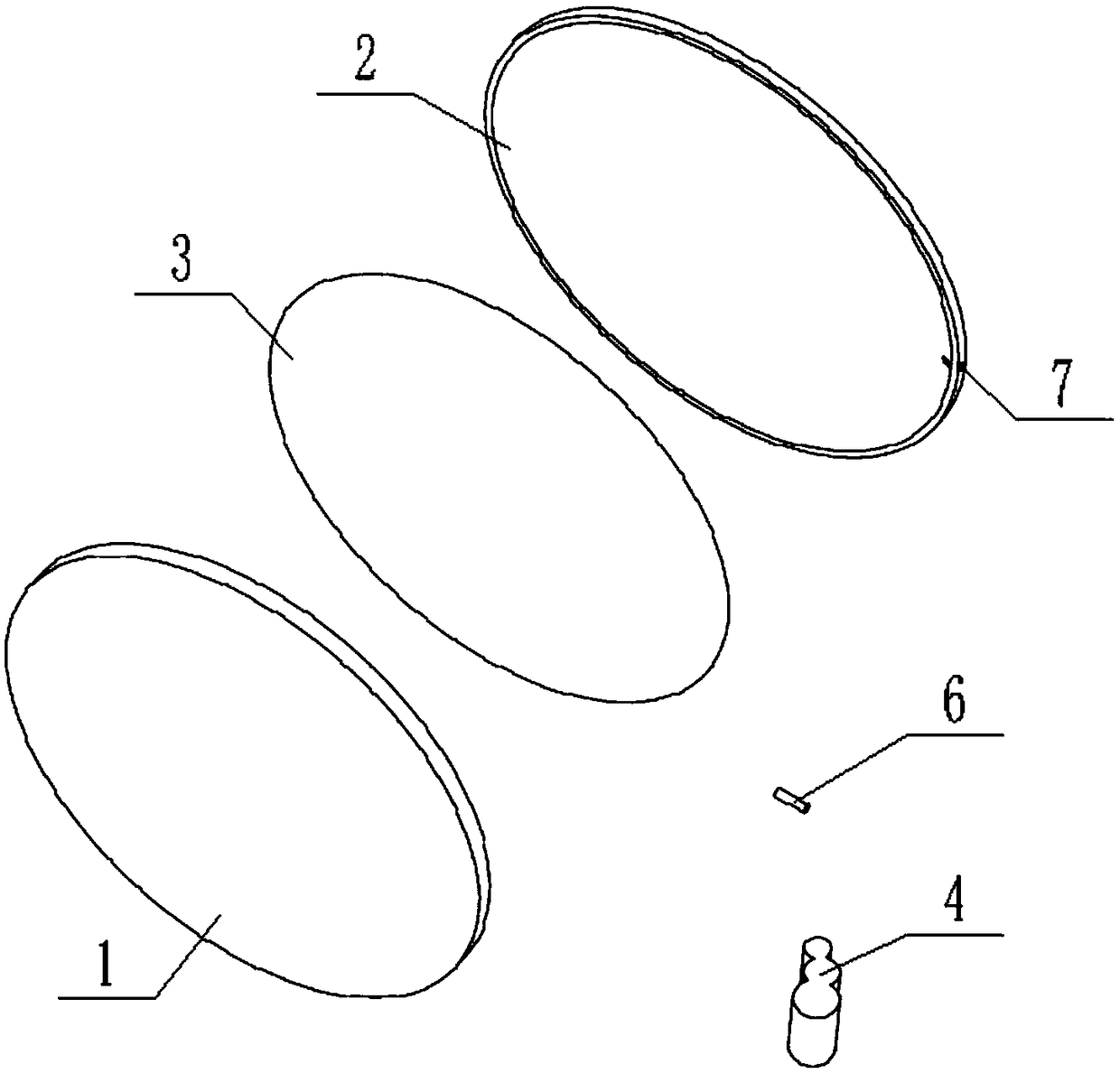

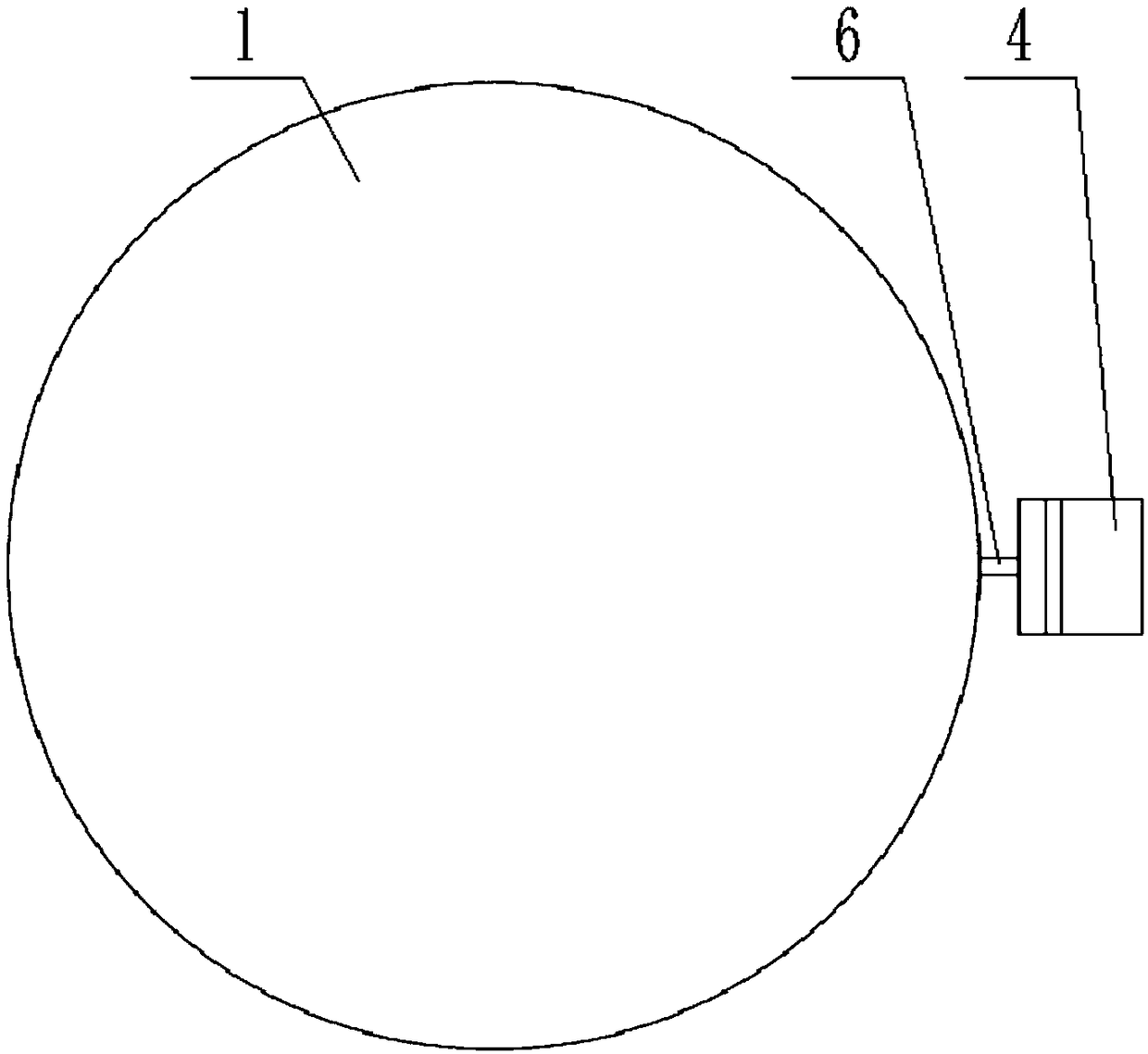

[0040] figure 1 , figure 2 , image 3 They are the structure diagram, explosion diagram and plan diagram of the lens system provided by Embodiment 1 of the present invention, respectively. combine figure 1 , figure 2 and image 3 Shown:

[0041] The lens system provided by Embodiment 1 of the present invention includes: a substrate 1 , an attachment 2 , a transparent fluid 3 , a pressure regulator 4 and a conduit 6 . Wherein, the edge of the substrate 1 and the attachment 2 is connected, the transparent fluid 3 is filled between the substrate 1 and the attachment 2, the pressure regulator 4 increases or decreases the filling pressure of the transparent fluid 3 through the conduit 6, and changes the pressure of the substrate. 1 and the volume of the transparent fluid 3 in the closed cavity (not shown) formed between the attached sheet 2, and then change its pressure on the substrate 1 and the attached sheet 2, so that the substrate 1, the transparent fluid 3 and the Th...

Embodiment 2

[0059] figure 1 , figure 2 , image 3 They are the structure diagram, explosion diagram and plan diagram of the lens system provided by Embodiment 2 of the present invention, respectively. combine figure 1 , figure 2 and image 3 Shown:

[0060] The lens system provided by the second embodiment of the present invention includes: a substrate 1 , an attachment 2 , a transparent fluid 3 , a pressure regulator 4 and a conduit 6 . Wherein, the edge of the substrate 1 and the attachment 2 are connected, the transparent fluid 3 is filled between the substrate 1 and the attachment 2, the pressure regulator 4 increases or decreases the filling pressure of the transparent fluid 3 through the conduit 6, and changes the pressure of the substrate. The volume of the transparent fluid 3 in the closed cavity formed between 1 and the attached sheet 2, and then change its pressure on the substrate 1 and the attached sheet 2, so that the combination of the substrate 1, the transparent fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com