Thermal-state steel tube thickness online detection device

A technology for detection devices and steel pipes, applied in measuring devices, optical devices, instruments, etc., can solve the problems of low receiving frequency of air-coupled sensors, lower signal-to-noise ratio of interferometer demodulated signals, and difficult signal processing, etc., to ensure optical Features and stability, relaxed working environment, less external interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

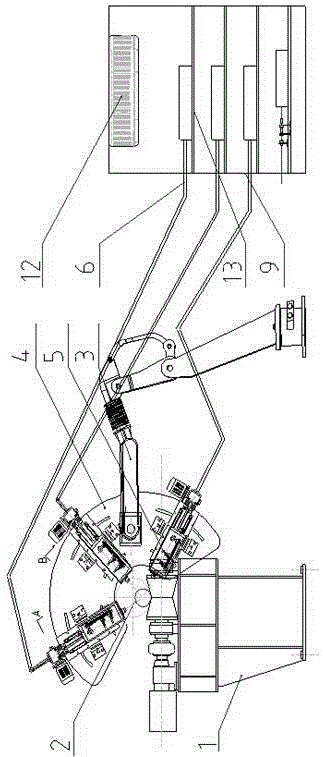

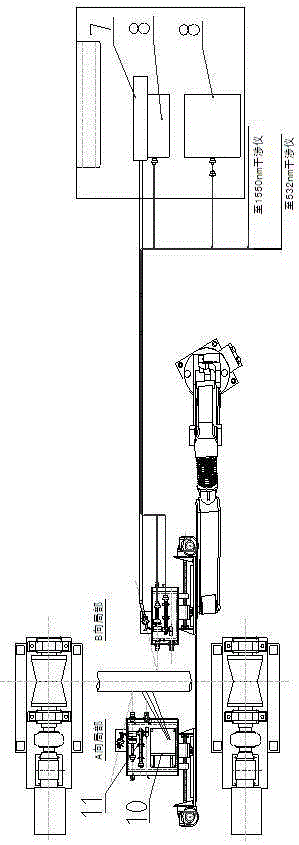

[0026] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes the hot steel pipe 2 erected on the roller table 1, the periphery of the hot steel pipe 2 is provided with a centripetal backboard 4 erected by the mechanical arm 3, and the centripetal backboard 4 is provided with several steel pipes corresponding to the center of the steel pipe 2. The detection head 5 has a long focal length lens and a large depth-of-field lens placed inside the detection head 5; the detection head 5 is respectively connected to the pulse laser 7 and the continuous laser 8 through the light guide arm 6, and the continuous laser 8 and the detection head are laid in the light guide arm 6 5 optical fibers, and the joints of the light guide arm 6 are provided with multi-level mirrors for conducting high-power pulsed lasers; the pulsed laser 7 and the continuous laser 8 are placed in a refrigeration cabinet 9 away from the steel pipe 2, and the pulsed la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com