Liquid removing device of optical film

An optical film and angle adjustment technology, which is applied in the field of optical film, can solve the problems of non-reducing defects, rising costs, and inability to completely remove liquid, so as to improve applicability and maintainability, and ensure optical characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

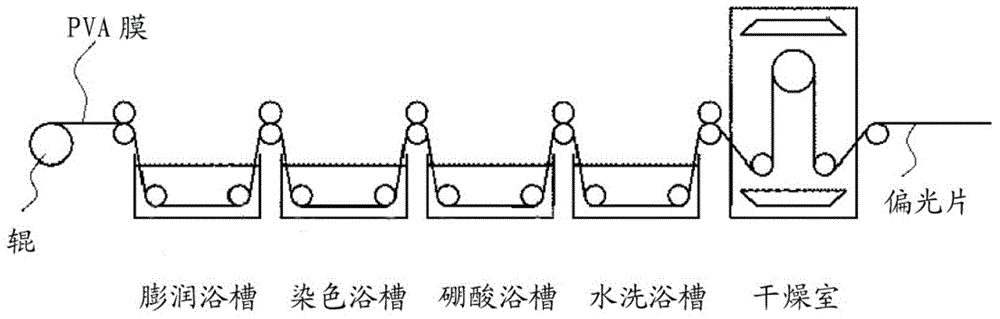

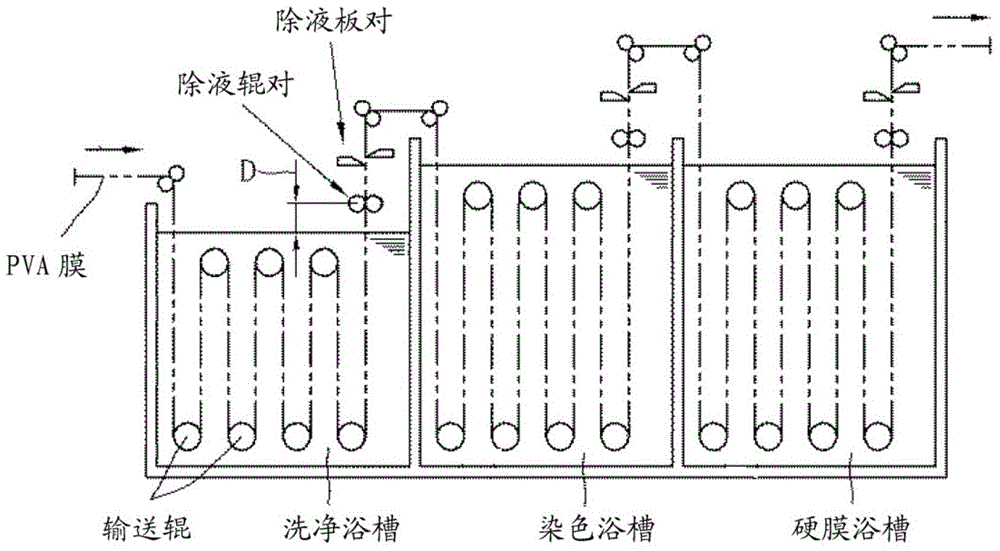

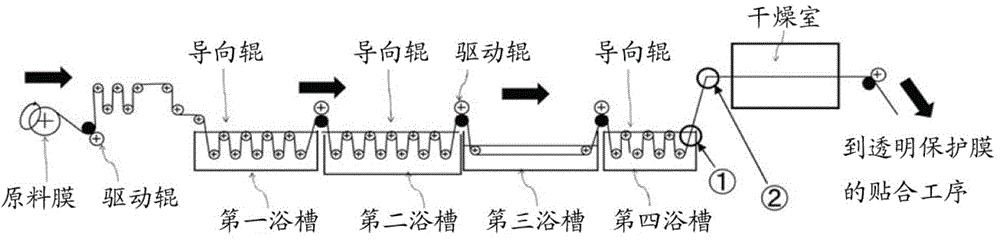

Method used

Image

Examples

no. 1 example

[0132] Such as Figure 12 As shown, in the liquid removal device of the first embodiment, the first liquid removal mechanism and the second liquid removal mechanism are respectively fixed at a predetermined distance from the polarizer with respect to the polarizer moving in the up and down direction (the first specified distance). An example of distance). This fixing method is beneficial to the situation where the installation place of the liquid removal device is relatively narrow. In the case of the composition of the first embodiment, the liquid removal device adjusts the angles of the plate parts of the first liquid removal mechanism and the second liquid removal mechanism to move the plate parts toward the polarizer in the standby state (such as Figure 12 (shown by the black dotted line in the up and down direction), and then before the water removal process starts, loosen the fixing bolt or the holding mechanism shaft fastening bolt to adjust the holding mechanism shaf...

no. 2 example

[0135] The liquid removal device of the first embodiment is fixedly installed, and the liquid removal device of the second embodiment is as Figure 13 As shown, each of the first liquid removal mechanism and the second liquid removal mechanism also has a guide part provided under the angle adjustment table, an air cylinder (an example of a moving mechanism) connected to the guide part, and the guide part is provided on the upper side. At this time, the first liquid removal mechanism and the second liquid removal mechanism move back and forth (the front close to the polarizer and the rear away from the polarizer) along with the telescopic action of the cylinder. In this case, when the guide part abuts against the guide part stopper provided at the front end of the guide rail, that is, at the end close to the polarizer, or through the perception of a laser sensor or a proximity sensor provided on each angle adjustment table, The angle adjustment table on the guide rail can be st...

no. 3 example

[0141] The liquid removal device of the third embodiment is as Figure 14 As shown, different from the first embodiment and the second embodiment, one of the first liquid removal mechanism and the second liquid removal mechanism adopts the composition of the first embodiment, while the other liquid removal mechanism adopts the second embodiment The composition of the example.

[0142] In addition, the pressing force of the plate member of the liquid removal device on the polarizer is set in advance in consideration of water removal performance, damage to the polarizer, and the like. If the degree of contact between the plate member and the polarizer is weak, the dewatering property will be reduced, causing problems. If the degree of contact is too strong, the polarizer will be damaged. In this case, the worst case is that the polarizer is broken. Therefore, if Figure 15 As shown, in order to make the pressing force of the plate member on the polarizer reach the set value, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com