Mooring cable for large-length unmanned aerial vehicle

A large-length, unmanned aerial vehicle technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problem that the cable easily exceeds the load-bearing capacity of the unmanned aerial vehicle, affects the safe operation of the unmanned aerial vehicle system, and the unmanned aerial vehicle cannot operate normally. , to achieve the effect of light weight, appropriate mechanical strength and wear resistance, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

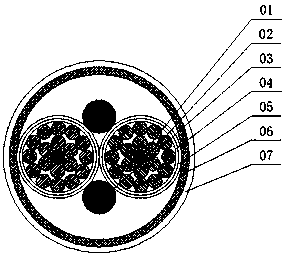

[0015] Composite tinned copper conductor, this product must not only ensure the current carrying capacity of electricity, but also have a certain tensile strength in consideration of its own weight. The conductor structure uses multi-core regular stranded conductors, each strand is made of tinned Composed of copper wire, it is round and soft. At the same time, in the design of the conductor, strand-packed aramid fibers are chosen as the central layer to be twisted into the conductor, and the tight compression method is used to form a whole with other copper strand bundles to improve the tensile properties of the conductor.

[0016] Insulation and outer sheath material X-ETFE material, fluoroplastic: the selection of X-ETFE wire has many advantages similar to other fluoroplastics, such as excellent high temperature resistance and low temperature resistance; good flame retardancy; excellent chemical medium resistance, medium Excellent electrical properties; suitable mechanical s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking force | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com