Alloy material for heart stent with anti-allergy function

An alloy material and a technology for cardiac stents, which are applied in the field of cardiac stents with anti-allergic function, can solve the problems of vascular intimal hyperplasia, limited use range, and unsatisfactory vascular support performance.

Inactive Publication Date: 2019-03-01

周万芳

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Many coronary heart disease patients with severe tubular artery stenosis cannot be effectively reversed by drug treatment, and interventional therapy or thoracotomy is required. Interventional therapy can effectively solve coronary artery stenosis and reduce the risk of surgery. At present, interventional materials such as cobalt Alloys, titanium alloys, and stainless steel materials can lead to vascular intimal hyperplasia after long-term implantation in blood vessels, thereby increasing the time of late thrombosis, and biodegradable polymer materials such as polylactic acid, because their vascular support performance cannot meet the requirements, limit this type of treatment. The scope of use of materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

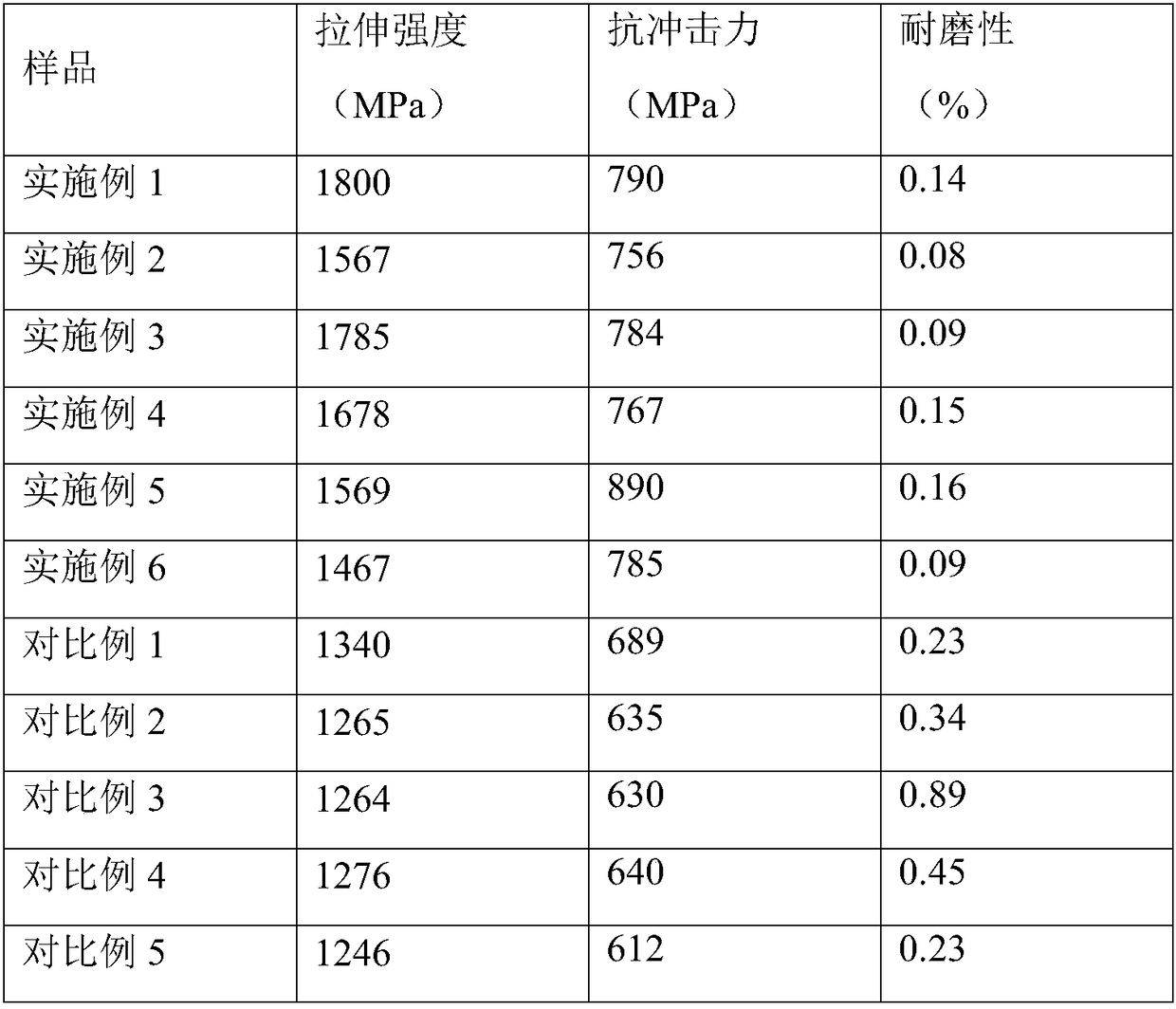

Effect test

Embodiment 1

[0011] Example 1: 0.5% Nd, 0.3% Ce, 5% W, 0.1% Mo, 2% polymer material collagen, and the rest is Mg.

Embodiment 2

[0012] Example 2: 3% Nd, 1% Ce, 8% W, 0.8% Mo, 3% polymer material chitosan, and the rest is Mg.

Embodiment 3

[0013] Example 3: 1% Nd, 0.5% Ce, 6% W, 0.3% Mo, 2% polymer material polylactic acid, and the rest is Mg.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an alloy material for a heart stent having an anti-allergic function. The alloy material is prepared from the following components in percentage by mass: 0.5 to 3% of Nd, 0.3 to 1% of Ce, 5 to 8% of W, 0.1 to 0.8% of Mo, 2 to 3% of a polymer material and the balance of Mg. The heart stent material disclosed by the invention has the anti-allergy property and is high in resistance to corrosion of organic substances and alkali.

Description

technical field [0001] The invention relates to a heart stent, in particular to a heart stent with antiallergic function. Background technique [0002] Many coronary heart disease patients with severe tubular artery stenosis cannot be effectively reversed by drug treatment, and interventional therapy or thoracotomy is required. Interventional therapy can effectively solve coronary artery stenosis and reduce the risk of surgery. At present, interventional materials such as cobalt Alloys, titanium alloys, and stainless steel materials can lead to vascular intimal hyperplasia after long-term implantation in blood vessels, thereby increasing the time of late thrombosis, while biodegradable polymer materials such as polylactic acid cannot meet the requirements for vascular support performance, which limits this type of treatment. The scope of use of the material. Contents of the invention [0003] Purpose of the invention: In order to solve the problems of the above-mentioned ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A61L31/06A61L31/04A61L31/02A61L31/14C22C23/00

CPCA61L31/044A61L31/022A61L31/042A61L31/06A61L31/14A61L31/148C22C23/00C08L5/08C08L67/04C08L75/04

Inventor 周万芳

Owner 周万芳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com