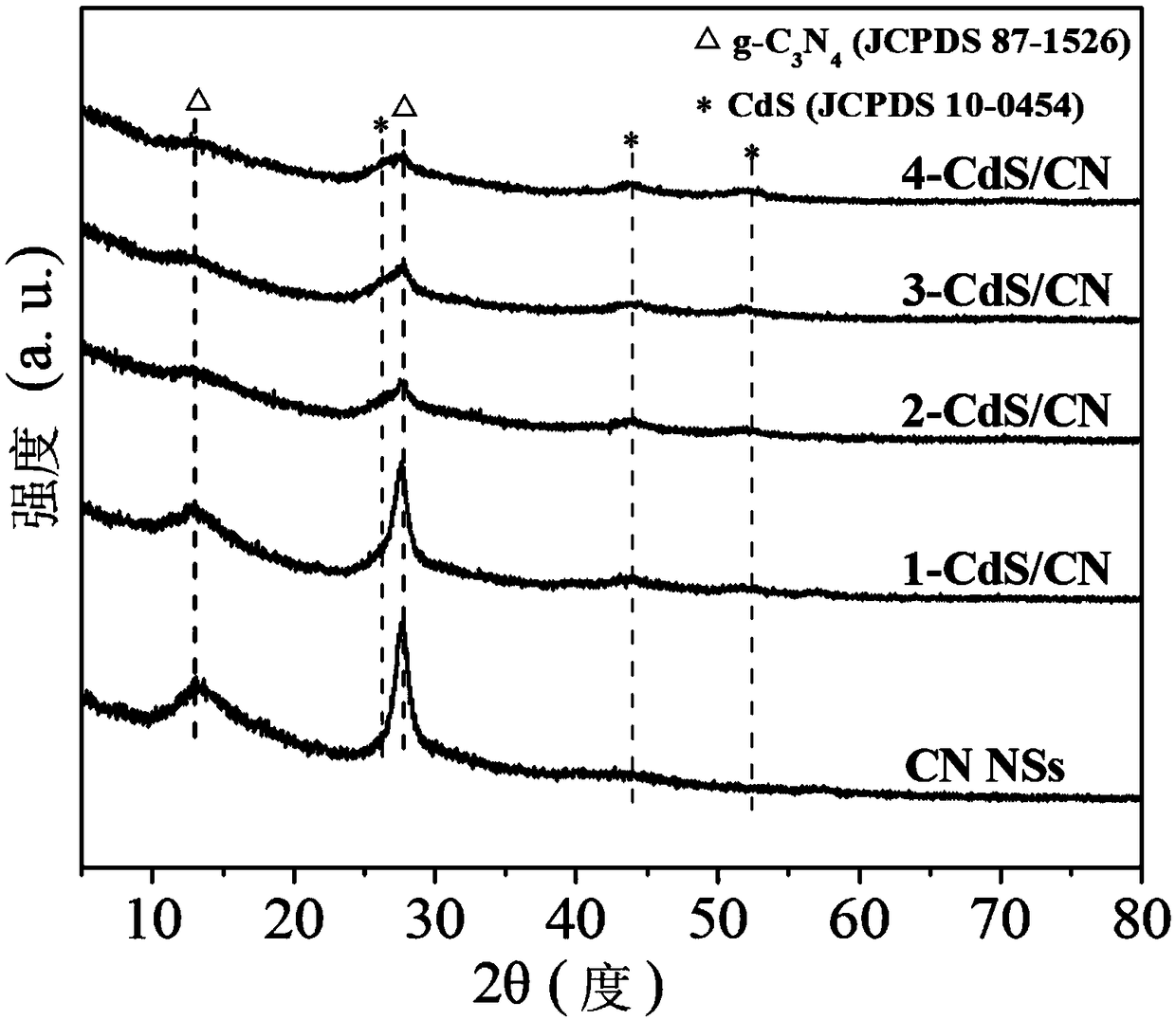

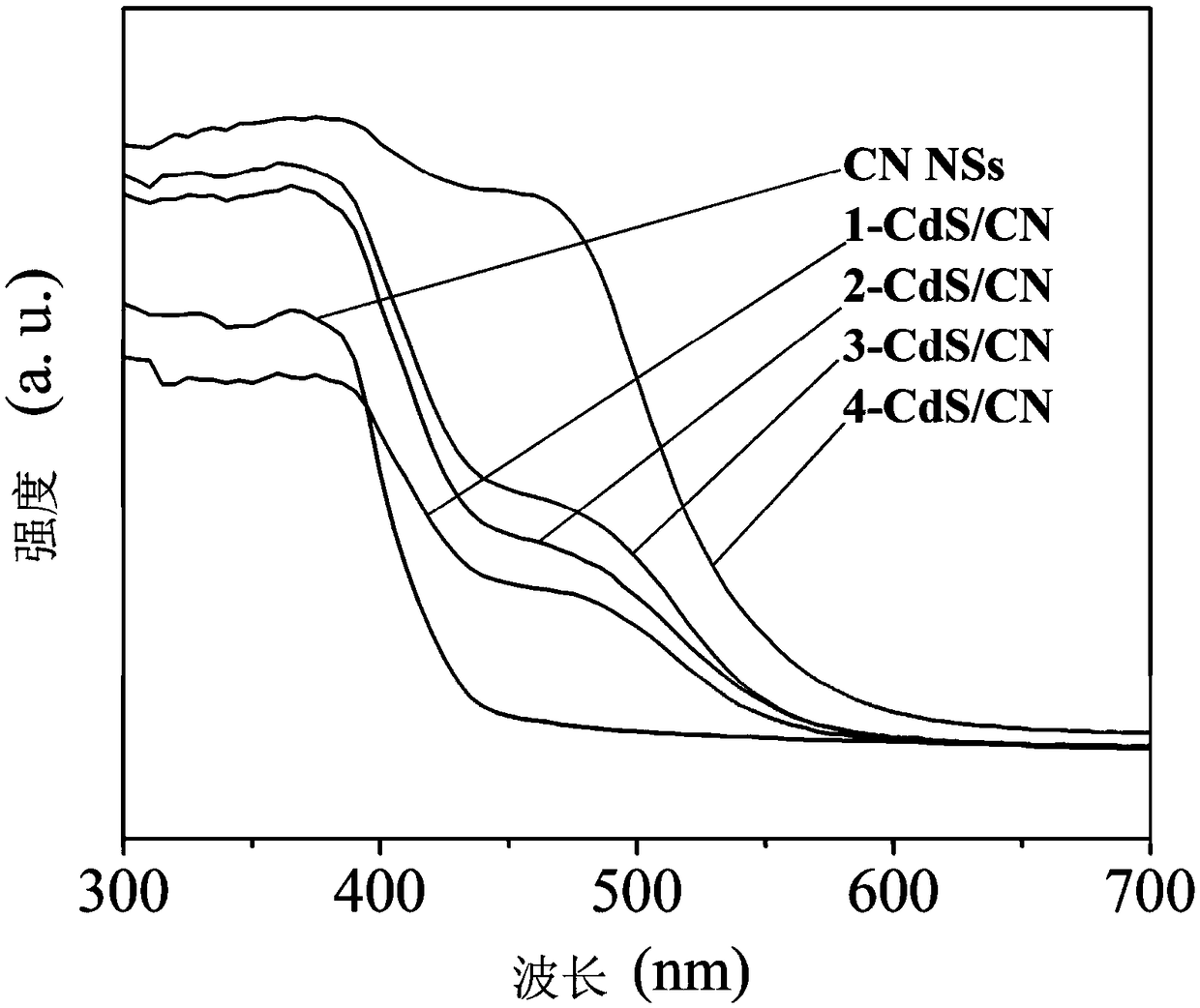

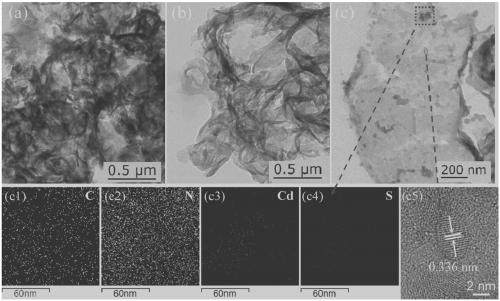

Preparation method and application of two-dimensional thin layer CdS/g-C3N4 composite photocatalyst

A g-c3n4, composite light technology, applied in physical/chemical process catalysts, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as restricting practical application, high cost, secondary pollution, etc., to improve visible light response. Ability, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Two-dimensional thin-layer g-C 3 N 4 Precursor preparation:

[0032] Put 10g of urea into an alumina crucible, and calcine it in a muffle furnace at a high temperature of 550°C (the heating rate is 5°C / min) for 4h;

[0033] (2) Two-dimensional thin-layer g-C 3 N 4 Preparation of nanosheets:

[0034] The two-dimensional thin layer g-C 3 N 4 The precursor was added to the nitric acid solution with pH = 1, stirred for 8 hours under the condition of heating in water at 80°C, and then the obtained sample was washed several times, dried in vacuum at 60°C, and then calcined at 500°C for 2 hours, and then cooled to room temperature , Grinding to get two-dimensional thin layer g-C 3 N 4 Nanosheets.

[0035] (3) Two-dimensional thin layer CdS / g-C 3 N 4 Preparation of composite photocatalyst:

[0036] The sample obtained in 100mg (2) was mixed with 50ml of Cd(NO 3 ) 2 The aqueous solution was sonicated for 10 minutes, and after complete dispersion, the sample was...

Embodiment 2

[0039] (1) Two-dimensional thin-layer g-C 3 N 4 Precursor preparation:

[0040] Put 10g of urea into an alumina crucible, and calcine it in a muffle furnace at a high temperature of 550°C (the heating rate is 5°C / min) for 4h;

[0041] (2) Two-dimensional thin-layer g-C 3 N 4 Preparation of nanosheets:

[0042] The two-dimensional thin layer g-C 3 N 4 The precursor was added to the nitric acid solution with pH = 1, stirred for 8 hours under the condition of heating in water at 80°C, and then the obtained sample was washed several times, dried in vacuum at 60°C, and then calcined at 500°C for 2 hours, and then cooled to room temperature , Grinding to get two-dimensional thin layer g-C 3 N 4 Nanosheets.

[0043] (3) Two-dimensional thin layer CdS / g-C 3 N 4 Preparation of composite photocatalyst:

[0044] The sample obtained in 100mg (2) was mixed with 50ml of Cd(NO 3 ) 2 The aqueous solution was ultrasonically treated for 10 minutes. After being completely dispersed...

Embodiment 3

[0047] (1) Two-dimensional thin-layer g-C 3 N 4 Precursor preparation:

[0048] Put 10g of urea into an alumina crucible, and calcine it in a muffle furnace at a high temperature of 550°C (the heating rate is 5°C / min) for 4h;

[0049] (2) Two-dimensional thin-layer g-C 3 N 4 Preparation of nanosheets:

[0050] The two-dimensional thin layer g-C 3 N 4 The precursor was added to the nitric acid solution with pH = 1, stirred for 8 hours under the condition of heating in water at 80°C, and then the obtained sample was washed several times, dried in vacuum at 60°C, and then calcined at 500°C for 2 hours, and then cooled to room temperature , Grinding to get two-dimensional thin layer g-C 3 N 4 Nanosheets.

[0051] (3) Two-dimensional thin layer CdS / g-C 3 N 4 Preparation of composite photocatalyst:

[0052] The sample obtained in 100mg (2) was mixed with 50ml of Cd(NO 3 ) 2 The aqueous solution was sonicated for 10 minutes, and after complete dispersion, the sample was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com