Novel efficient thermal field control polishing machine and polishing method thereof

A polishing machine and high-efficiency technology, used in grinding/polishing equipment, optical surface grinders, metal processing equipment, etc., can solve the problems of obvious heat accumulation effect of optical components, affecting the surface quality of optical components, affecting the processing surface shape of optical components, etc. , to achieve the effect of improving the surface shape convergence efficiency, reducing the heat accumulation phenomenon, and evenly distributing the polishing powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

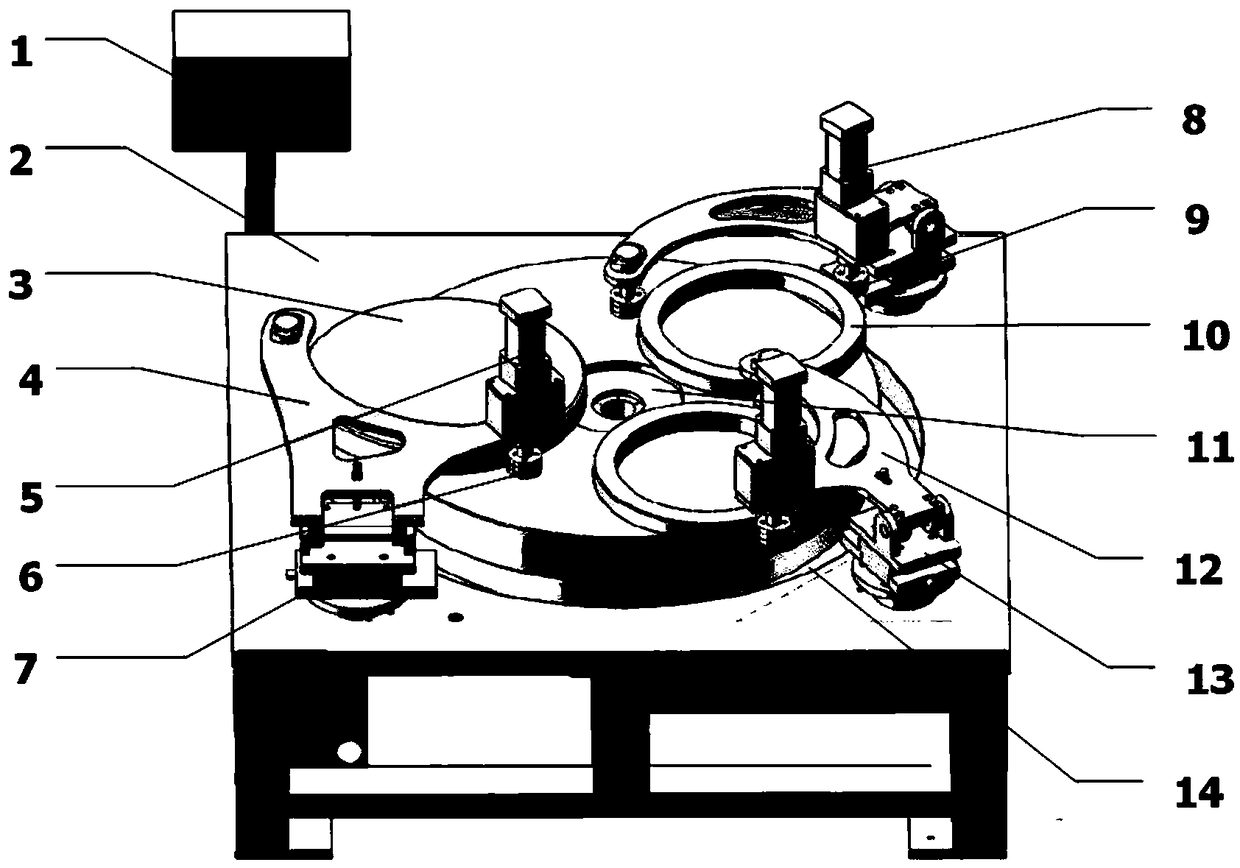

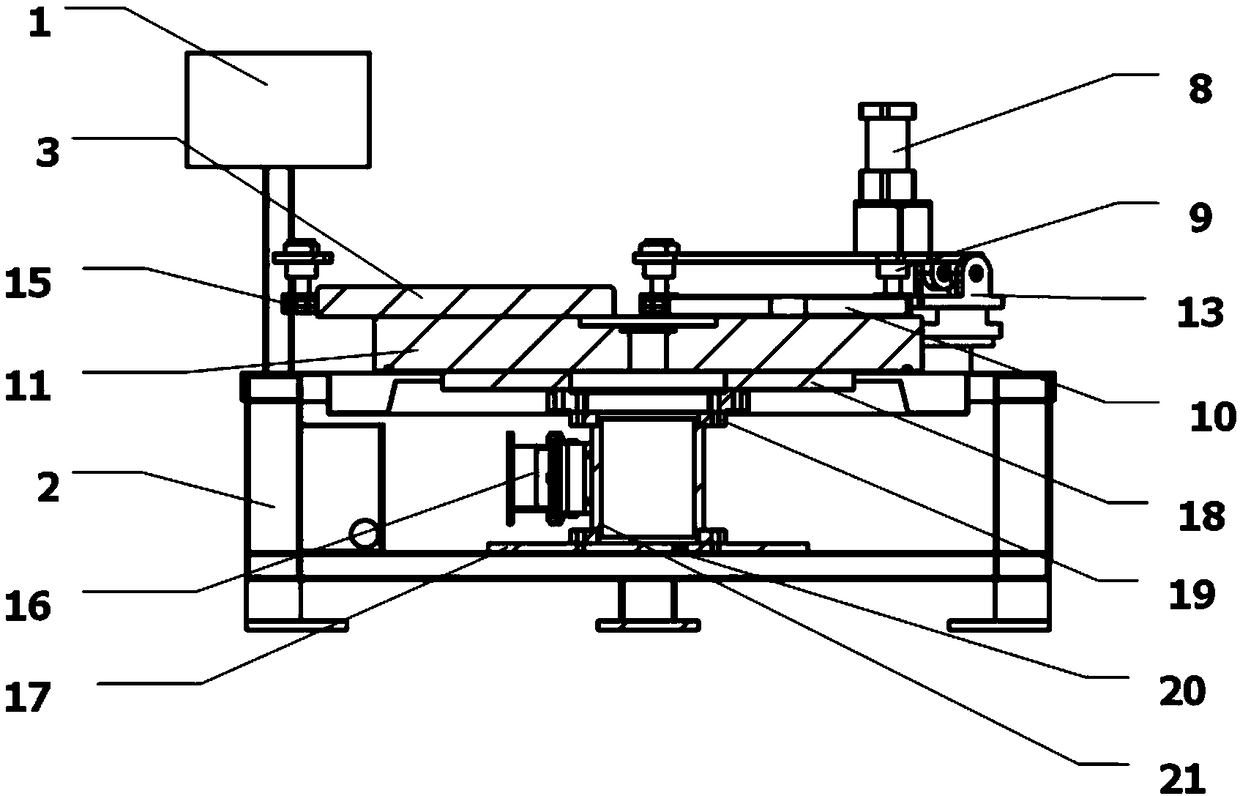

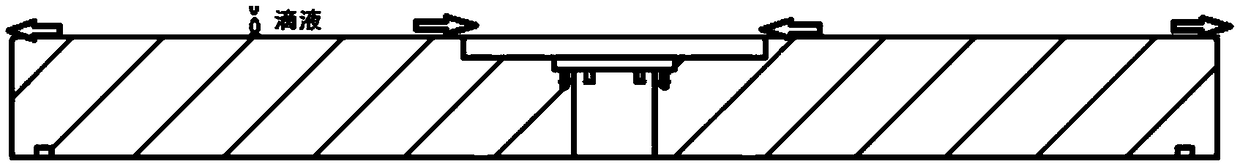

[0022] refer to figure 1 and figure 2 , figure 1 It is a structural schematic diagram of a novel high-efficiency thermal field control polishing machine of the present invention, figure 2 It is a sectional view of Embodiment 1 of the hollow marble disc polishing machine of the present invention. As can be seen from the figure, the present invention is a hollow marble disc polishing machine, which is characterized in that the polishing machine includes a control box 1, a frame 2, a calibration disc 3, a calibration disc pallet 4, a calibration disc drive motor 5, and a calibration disc drive wheel 6 , Calibration plate fixed base 7, workpiece ring drive motor 8, workpiece ring drive wheel 9, workpiece ring 10, hollow marble 11, workpiece ring supporting plate 12, workpiece ring base 13, water basin 14, correction disc wheel 15, motor 16. Lower supporting plate 17, tray 18, turntable bearing 19, water outlet 20 and cylindrical tray 21. Wherein, the diameter of the hollow s...

Embodiment 2~6

[0032] In Examples 2-6, the diameters of the hollow structures of the hollow marble 11 are respectively 1 / 4, 1 / 5, 1 / 6, 1 / 7 and 1 / 8 of the diameter of the polishing disc, and the hollow structures are all through holes. All the other structures and polishing methods are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com