Measuring device

A technology for measuring position and measuring head, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve problems such as affecting accuracy, and achieve the effect of prolonging processing cycle, low weight, and improving process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

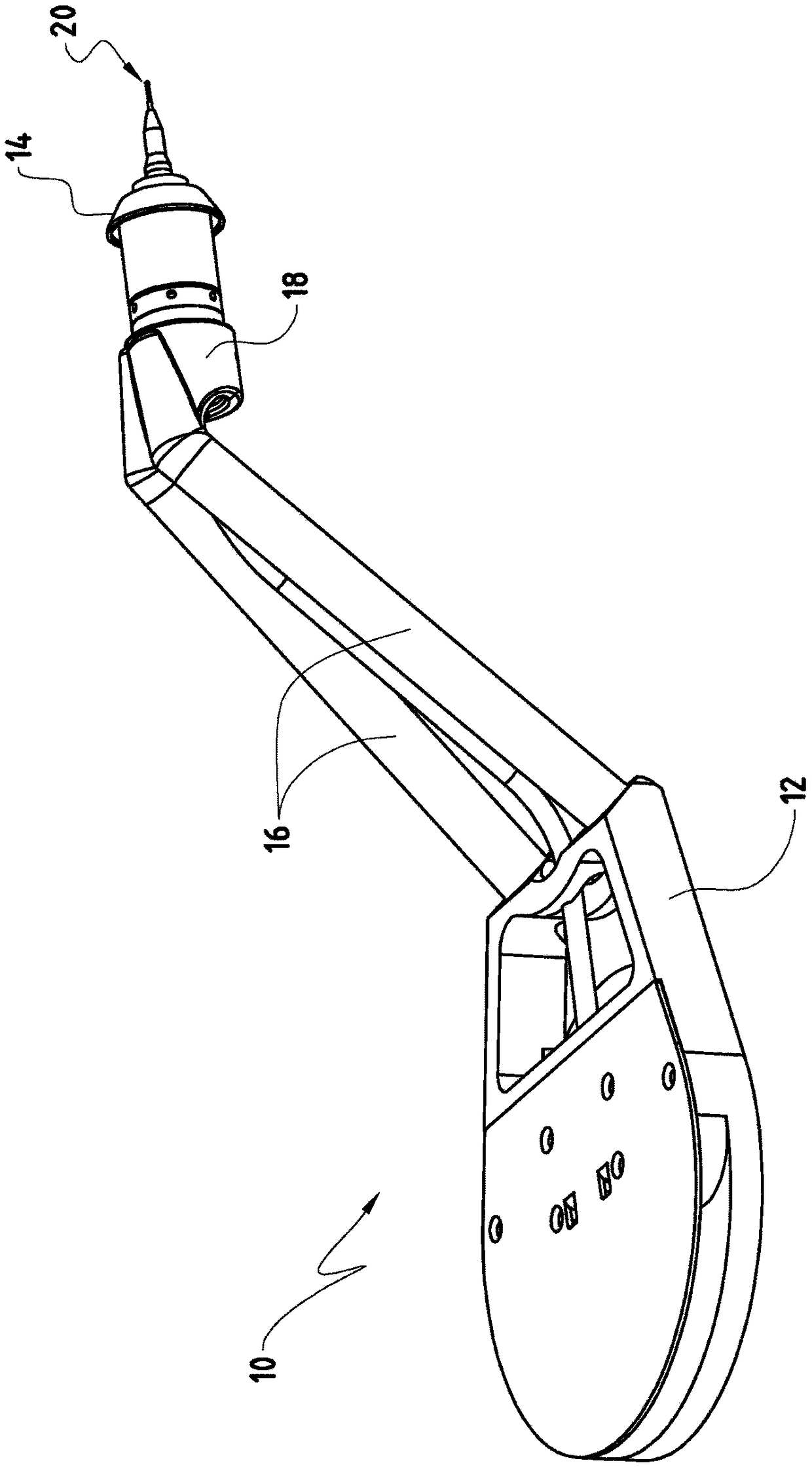

[0025] The measuring unit is in figure 1 is shown in and is denoted by "10" in its entirety. In this example, the measuring unit 10 is arranged in a machine tool, for example in a grinding machine. According to the invention, the measuring unit 10 is used for in-process measurement of a workpiece during a machining operation on a grinding machine. A grinding machine may have a grinding wheel fixed to the machine (grinding machine); the grinding wheel is rotatable about an axis of rotation and is used for machining workpieces. The measuring unit 10 comprises a base element 12 which may be arranged at a headstock (not shown) of the grinding machine so as to be pivotable about a pivot axis (not shown).

[0026]Furthermore, the measuring unit 10 comprises a measuring head 14 which is connected to the base element 12 of the measuring unit 10 by means of an arm 16 or more arms so as to be pivotable about a pivot axis. The measuring unit 10 also has means for pivoting the measurin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com