High pressure air bottle assembly mounting method for drilling ship

A technology of high-pressure air bottle and installation method, which is applied in ship parts, hull, ship construction, etc., can solve problems such as affecting the use of target equipment, reducing the reliability of target equipment, and residual water vapor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

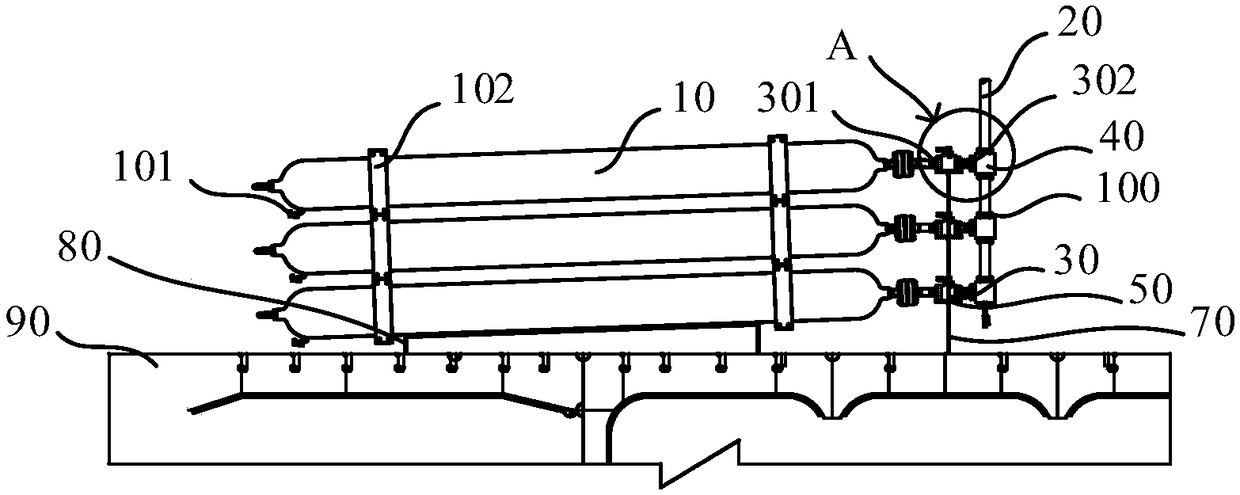

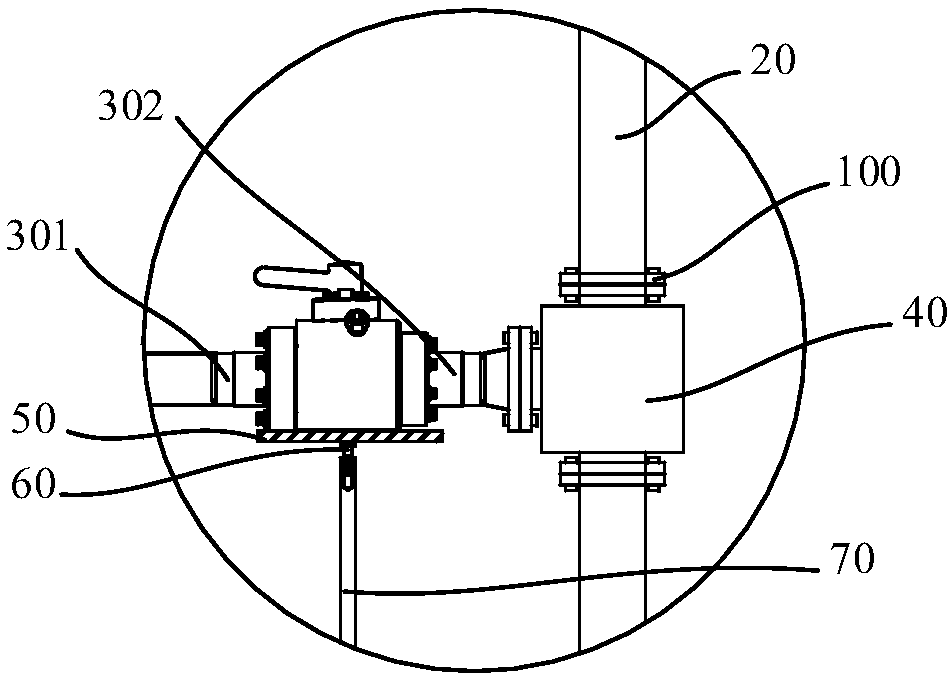

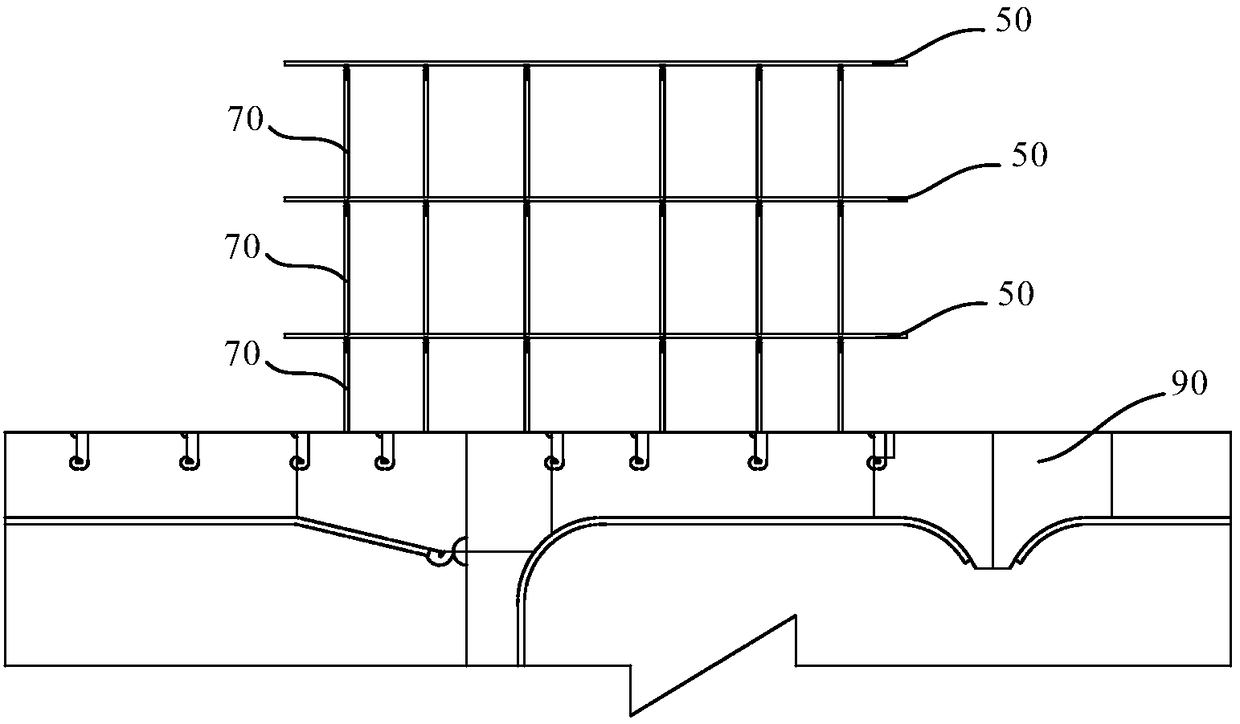

[0068] The drilling ship has a main deck and a lower deck, an accommodating cabin is formed between the main deck and the next deck, the high-pressure air cylinder assembly of the drilling ship is located in the accommodating cabin, and the next deck is provided with There is a base, and the high-pressure air bottle assembly is pressed on the base.

[0069] Wherein, the high-pressure air bottle assembly is arranged in multiple layers, each layer of the high-pressure air bottle assembly includes a plurality of high-pressure air bottles, and one layer of high-pressure air bottles close to the bottom plate in the multi-layer high-pressure air bottle Set on the base; among any adjacent two layers of high-pressure air bottles, one layer of high-pressure air bottles away from the bottom plate is pressed one by one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com