An automatic glaze spraying system for toilet body and its positioning method

A kind of toilet, blank technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

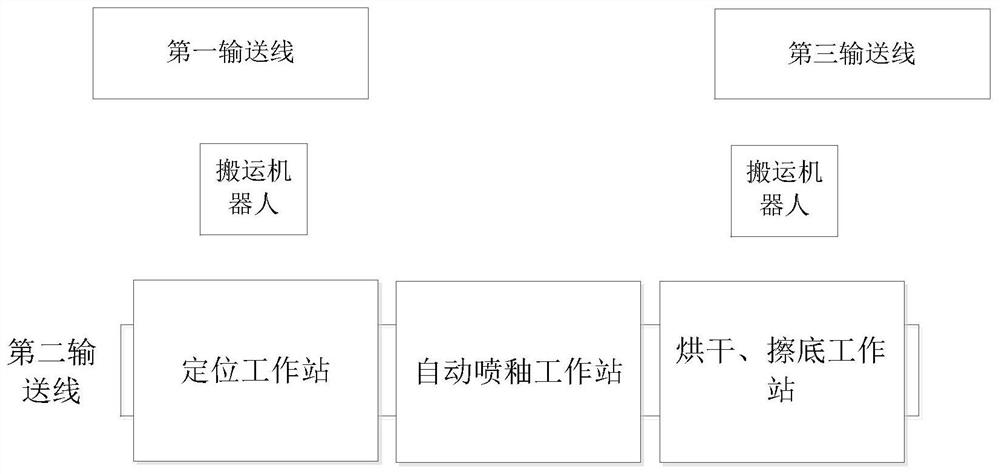

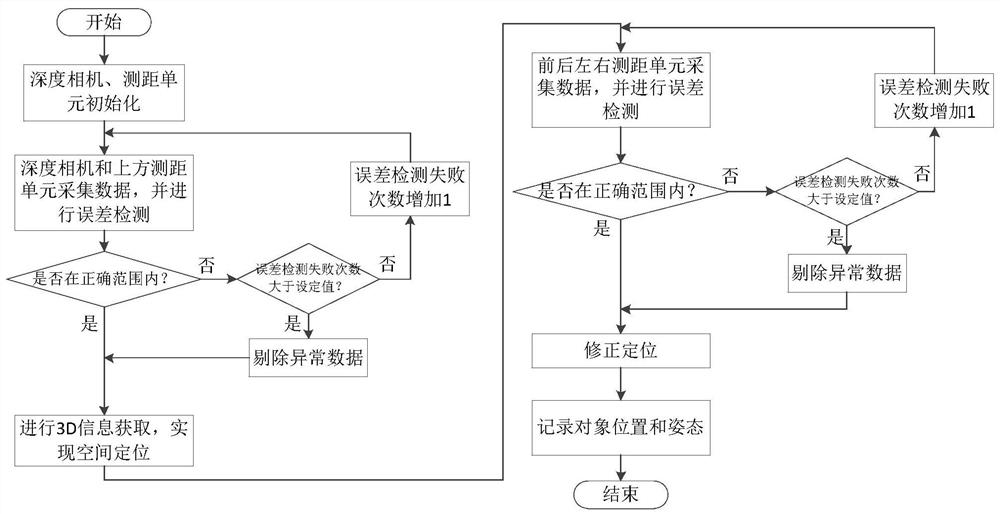

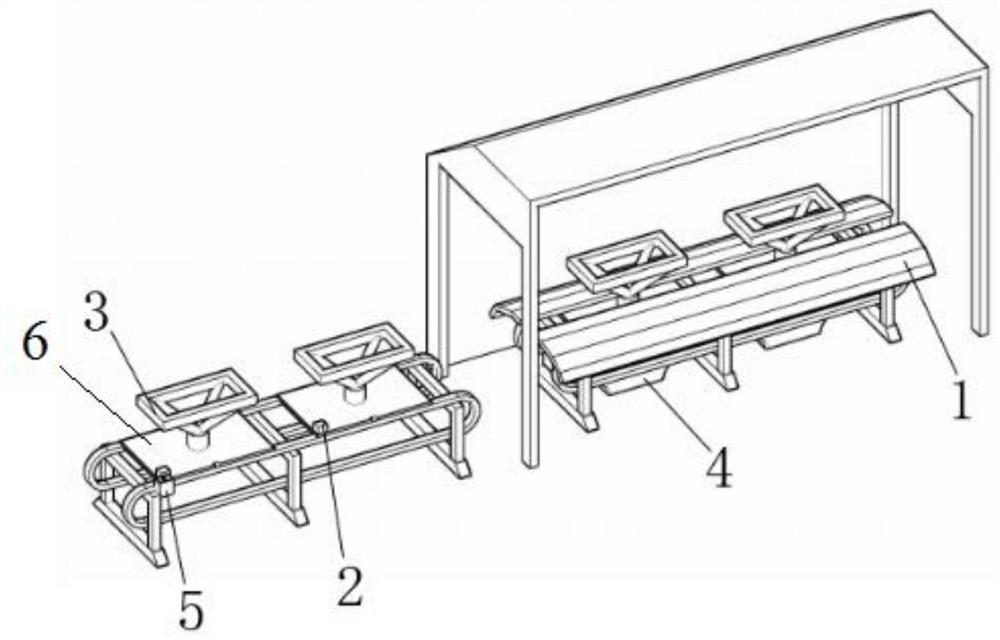

[0040] The invention discloses a fully automatic toilet pan glazing system which utilizes a glazing robot, multi-sensor data fusion and double closed-loop feedback control to realize precise positioning. The system includes three parts: a positioning workstation, a conveying line module and an automatic glazing workstation. The overall structure block diagram of the system is as follows: figure 1 As shown, the body of the toilet to be glazed is transported to the inlet of the second conveyor line through the first conveyor line, and the body is transferred from the first conveyor line to the second conveyor line by the handling robot; the second conveyor line Along the way, there are positioning workstations, automatic glaze spraying workstations, drying and bottom wiping workstations in sequence. The glazed toilets will be transferred from the second conveying line to the third conveying line by the handling robot to continue the subsequent processing technology. The present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com