Vacuum suction material conveying pump system

A technology of vacuum suction and conveying pump, applied in conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of high energy consumption and high construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

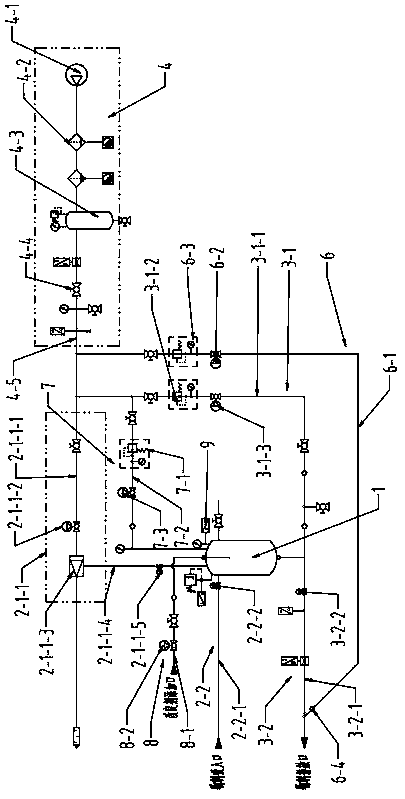

[0020] Embodiment 1: A vacuum suction conveying pump system, including a pressure vessel, a vacuum slag suction unit and a positive pressure slag discharge pumping unit; the vacuum slag suction unit sucks the slag into the pressure vessel through negative pressure, The pumping unit discharges the slag from the pressure vessel through positive pressure.

Embodiment 2

[0021] Embodiment 2: A vacuum suction conveying pump system, the vacuum slag suction unit includes a vacuum pumping assembly and a slag suction assembly, the vacuum pumping assembly includes a positive pressure generating component and a vacuum generating component, and the positive pressure generating component passes through The vacuum generating component communicates with the negative pressure suction port of the pressure vessel, the slag suction assembly includes a slag suction pipe and a pneumatic gate valve I; the slag suction pipe communicates with the slag inlet of the pressure vessel through the pneumatic gate valve I, and the positive pressure generating component , including air compressor, filter, air storage tank, manual ball valve, positive pressure pipeline Ⅰ; the positive pressure pipeline Ⅰ is equipped with air compressor, filter and air storage tank connected in sequence, and the positive pressure pipeline Ⅰ passes through the manual ball valve It communicate...

Embodiment 3

[0022] Embodiment 3: A vacuum suction conveying pump system, the positive pressure slag discharge pumping unit includes a positive pressure generating component, a positive pressure conveying component and a slag discharging component, and the positive pressure generated by the positive pressure generating component is conveyed through positive pressure The component is transported into the slag discharge assembly, the slag discharge port of the pressure vessel is connected with the slag discharge pipe of the slag discharge assembly, and the positive pressure generating components include air compressor, filter, gas storage tank, manual ball valve, positive pressure pipeline I The positive pressure pipeline I is provided with an air compressor, a filter and an air storage tank connected in sequence, and the positive pressure pipeline I communicates with the positive pressure pipeline III of the positive pressure delivery assembly through a manual ball valve, and the rest are the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com