Pearlescent composition

A composition and pearlescent technology, applied in the field of polymer compositions and plastics, can solve the problems of main components, container defects, compatibility, etc., and achieve the best pearlescent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

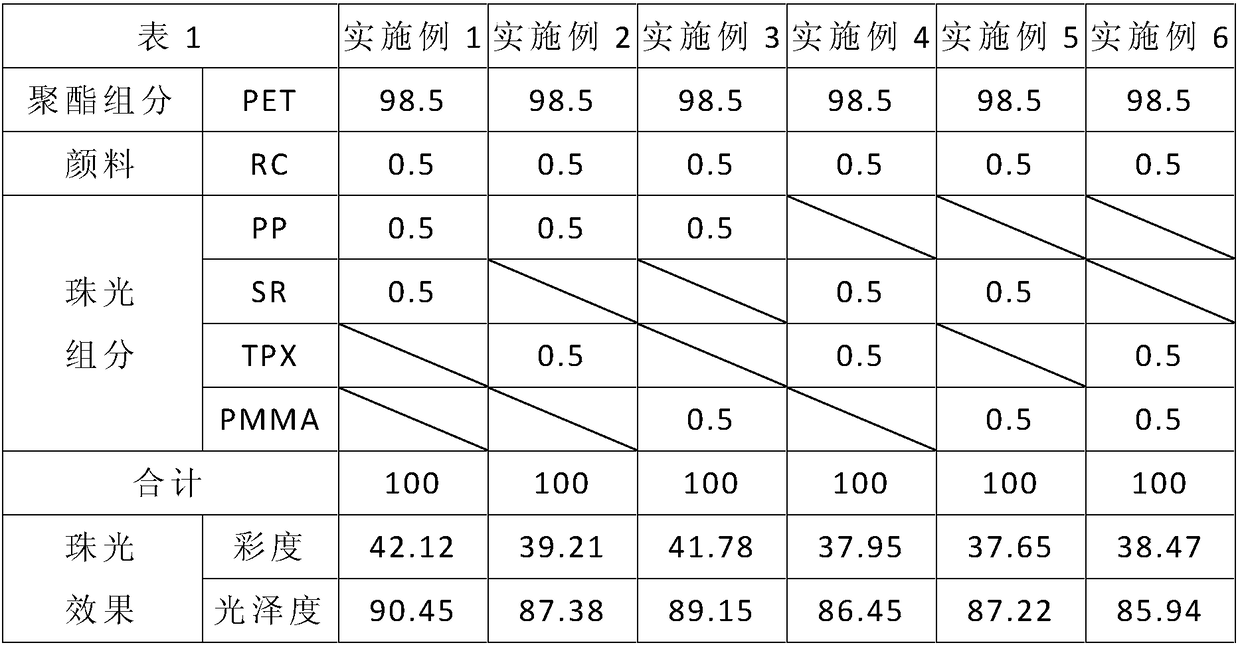

[0013] An example 1 of the pearlescent composition of the present invention includes 0.5 parts by weight of red pigment (Red Colorant, RC), 1 part by weight of pearlescent component, and the rest of polyester component. The pearl luster component includes a first component and a second component which are used in an amount of 0.5 parts by weight but of different materials. The first component is polypropylene (Polypropylene, PP), and the second component is silicone rubber (SR). The polyester component is polyethylene terephthalate (PET).

[0014] "Chroma and Gloss Measurement"

[0015] Example 1 was injection-molded into a pearlescent container with a capacity of about 500ml and a pearlescent effect, and the chromaticity of the pearlescent container was measured with an optical color difference instrument purchased from Datacolor Company, model 600TM, and was purchased from BYK-Gardner The company's gloss machine with a model of micro-gloss 60° measures the gloss of the pea...

Embodiment 2~6

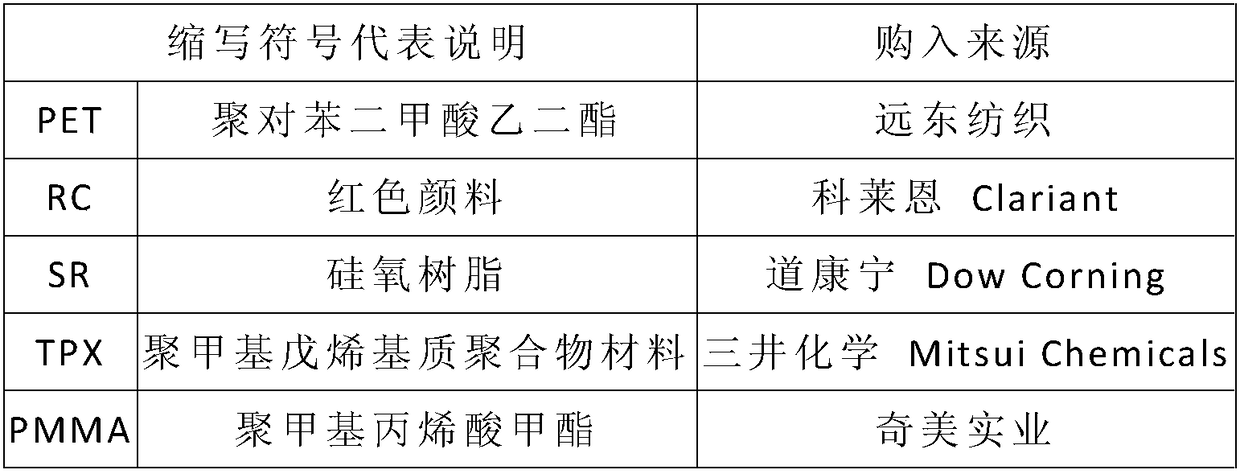

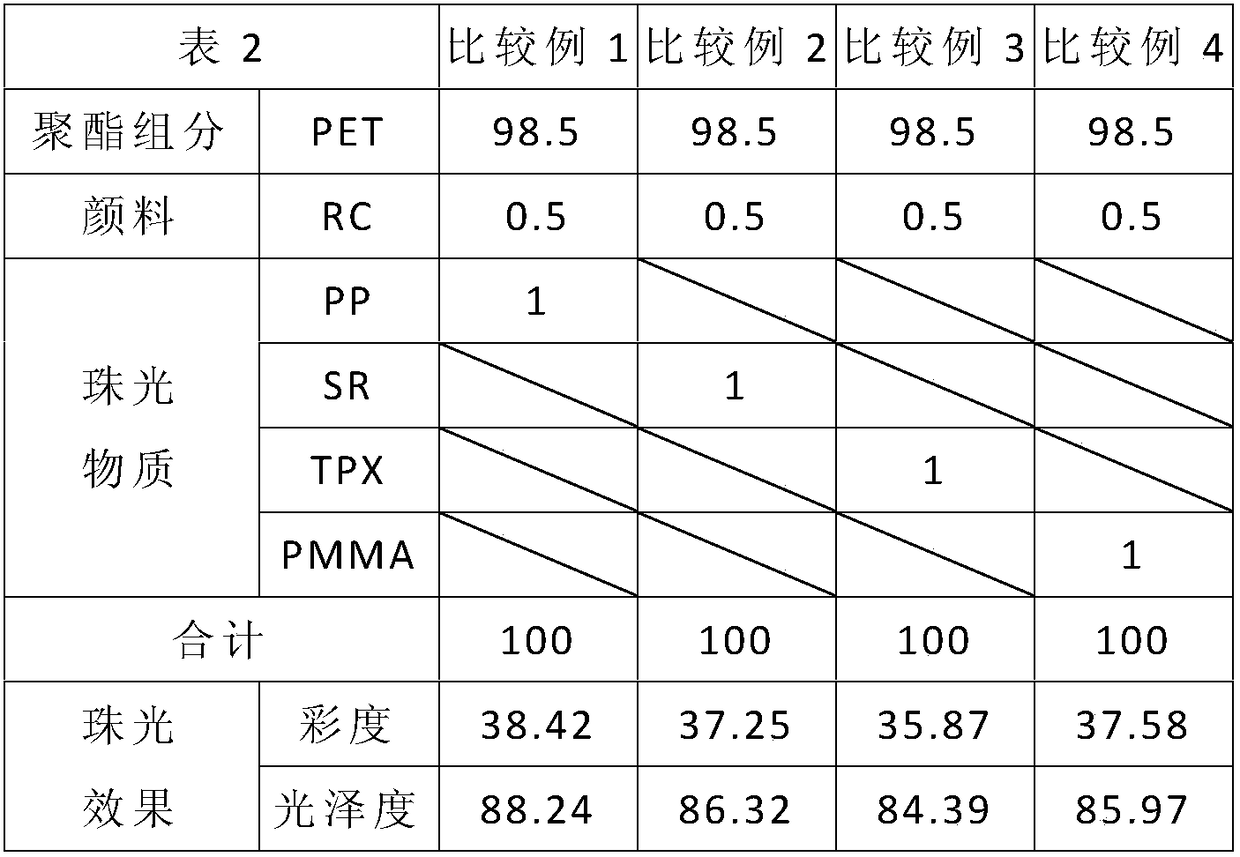

[0017] Embodiments 2-6 are similar to the embodiment 1, except that the pearlescent materials used in the first component and the second component are different. The pearlescent materials actually used in Examples 2-6 are recorded in Table 1. Measure the chroma and gloss of the pearl luster containers prepared in Examples 2-6, and record them in Table 1. Among them, the TPX used in Examples 2, 4, and 6 was purchased from Mitsui Chemicals, the product model is MX002, and it is a commercial product with polymethylpentene as the main component.

[0018]

[0019]

Embodiment 7~12

[0025] Examples 7-12 are similar to Examples 1-6, except that the pearlescent component is used in an amount of 10 parts by weight, and includes the first component and the second component in an amount of 5 parts by weight respectively. The materials used for the first component and the second component of Examples 7 to 12 are listed in Table 3. The chroma and glossiness of the pearl luster containers prepared in Examples 7-12 were measured and recorded in Table 3.

[0026]

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com