A control method of oxide inclusions in ultra-low carbon steel

A technology of ultra-low carbon steel and control method, which is applied in the direction of manufacturing converters, etc., to achieve the effect of remarkable and improved quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

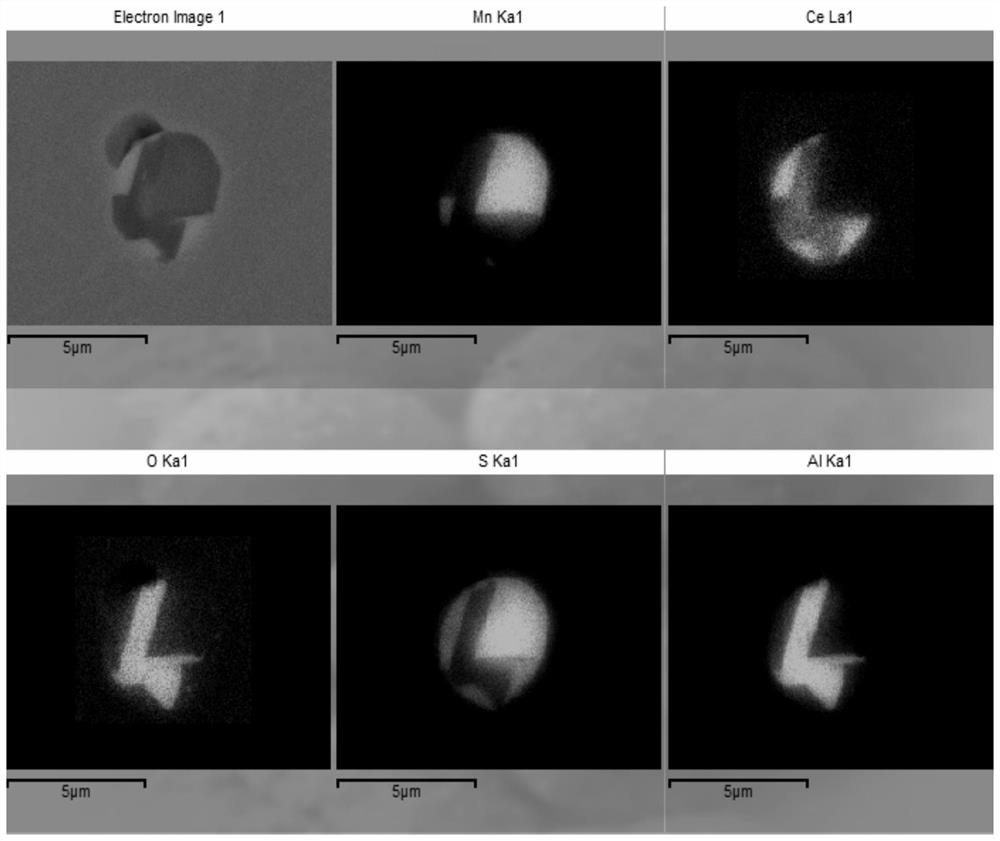

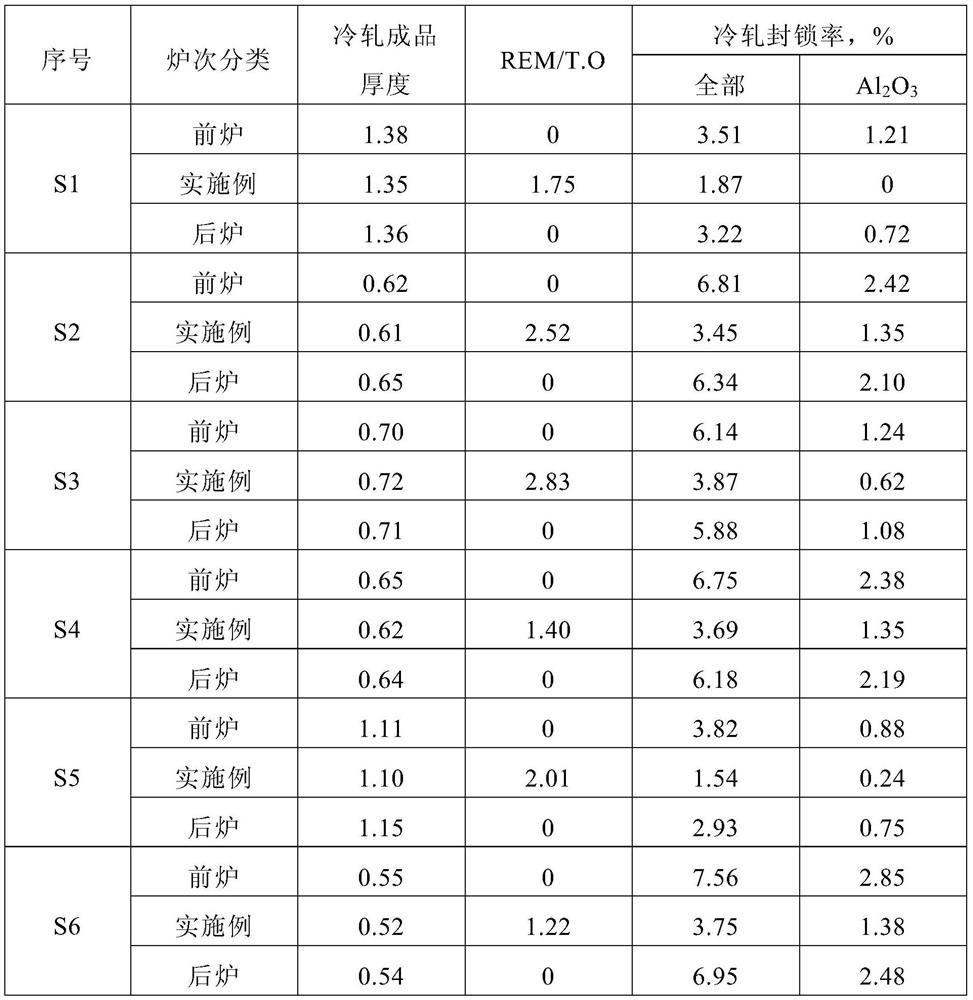

[0044] Converter blowing ends, [C] = 280ppm, [O] = 550ppm; slag blocking tapping, lime 3.32kg / t steel is added at the beginning of tapping, and aluminum slag 0.87kg / t steel is added at the end; ladle top slag composition before vacuum treatment (wt%FeO)+(wt%MnO)≤7.40, [(wt%CaO)+(wt%MgO)] / (wt%Al 2 o 3 )=1.72, the slag thickness is 118mm. After the vacuum decarburization is completed, Al is added to the molten steel for deoxidation and alloying, and the composition of the molten steel is adjusted to the specification range, [C]=20ppm, [Si]=0.01, [Mn]=0.65, [S]=120ppm, [Al ]=0.045, [Ti]=0.004, the molten steel circulates for 6.8 minutes; after the rare earth is added, the molten steel circulates for 4.2 minutes, the refining is completed, continuous casting, followed by hot rolling, pickling and cold rolling. Apex-Utral55 scanning electron microscope was used to count the inclusions in the slab, REM / T.O=1.75.

[0045] Embodiment 1 Process effect: For the judgment of the final ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com