Energy-saving tempering furnace

A tempering furnace and shell technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of low heating efficiency of energy-saving tempering furnaces, achieve good heating effects, reduce time and energy, and improve sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

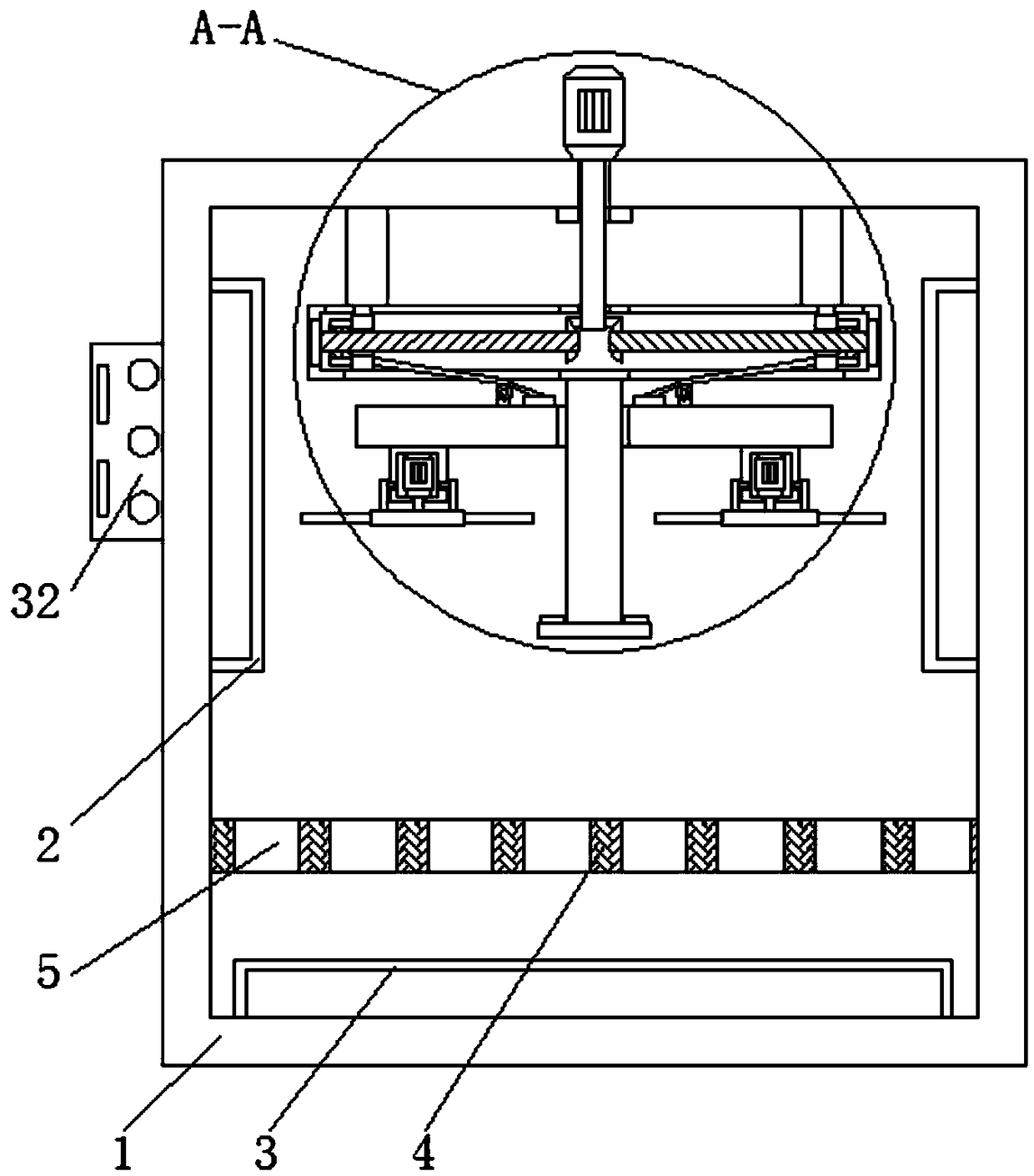

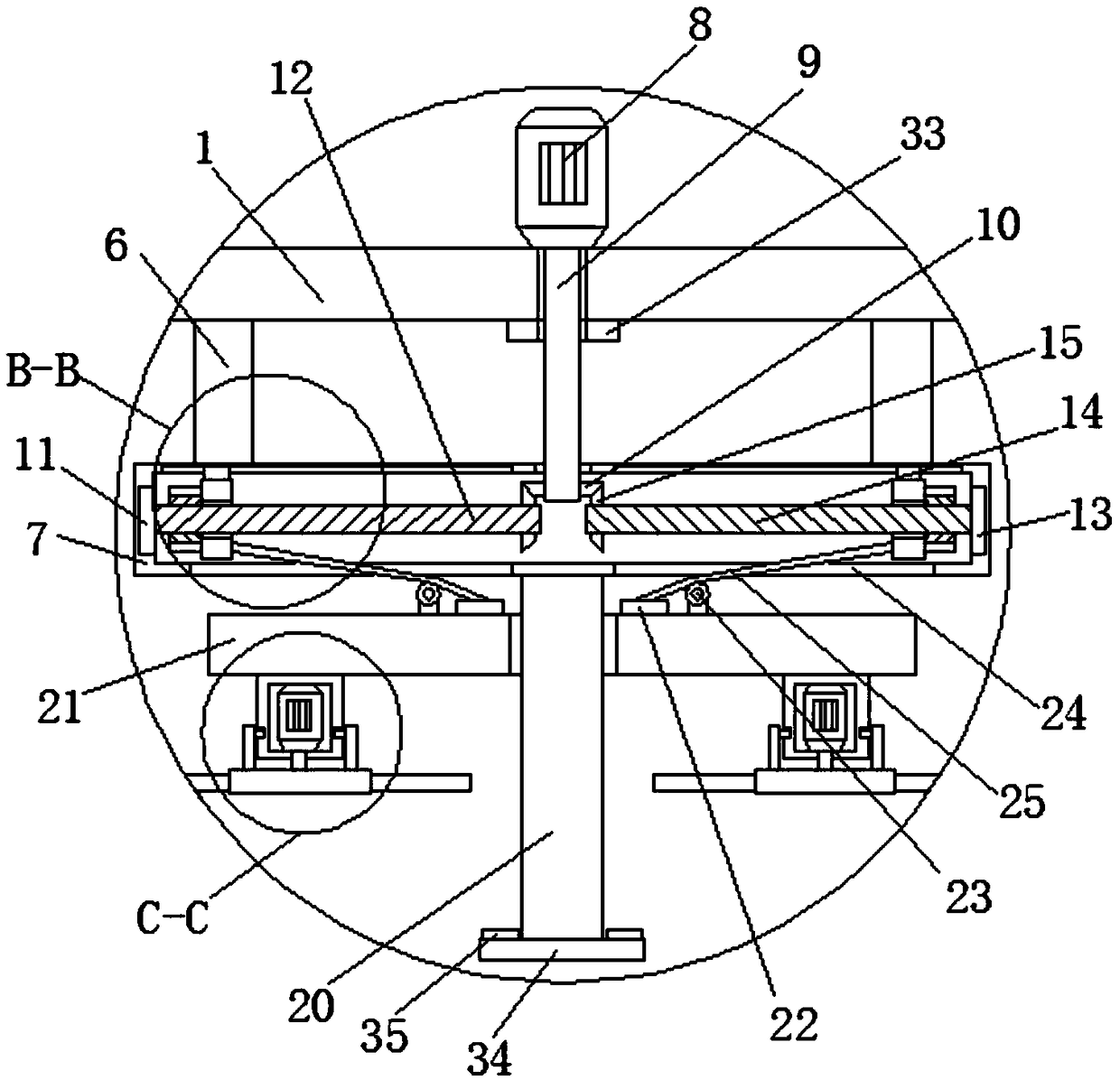

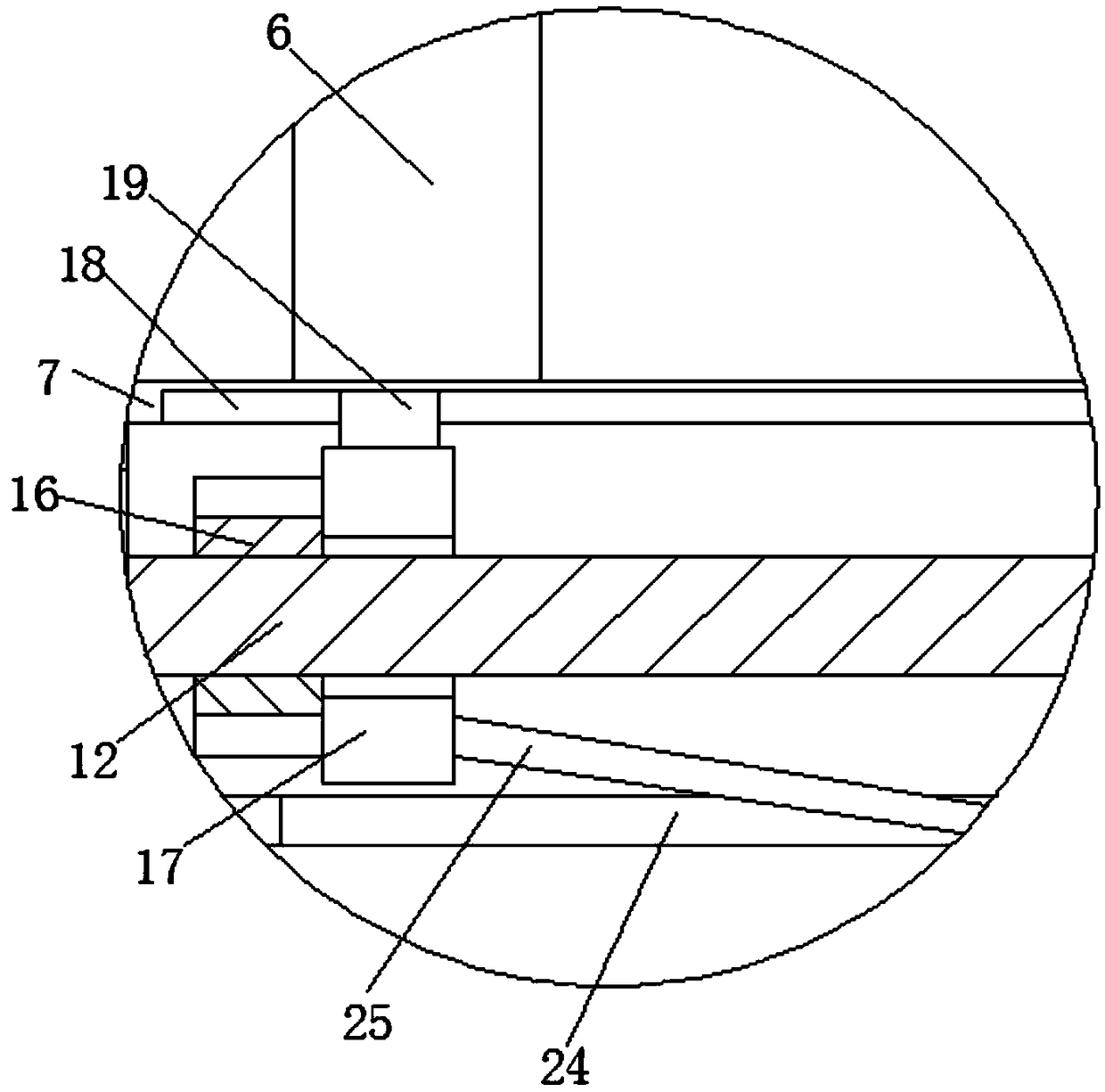

[0020] First implementation: see Figure 1-5, an energy-saving tempering furnace, comprising a shell 1, the top of the left and right sides of the inner wall of the shell 1 is fixedly connected with the first heating rod body 2, the bottom of the inner wall of the shell 1 is fixedly connected with the second heating rod body 3, the shell The inner wall of the housing 1 is fixedly connected with a stabilizing plate 4 above the second heating rod main body 3, the top of the stabilizing plate 4 is provided with a through hole 5, and the left and right sides of the top of the inner wall of the housing 1 are fixedly connected with a supporting plate 6, two The bottom of the support plate 6 is fixedly connected through the fixed shell 7, and the midpoint of the top of the shell 1 is fixedly connected with the rotating motor 8, and the output shaft of the rotating motor 8 is fixedly connected with the rotating shaft 9, and the bottom of the rotating shaft 9 is from top to bottom It r...

no. 2 approach

[0023] The second embodiment: as shown in claim 1, an energy-saving tempering furnace includes a shell 1, and the tops of the left and right sides of the inner wall of the shell 1 are respectively slidably supported and connected to a first heating rod body 2 through a chute, The chute has an initial damping, the bottom of the inner wall of the housing 1 is fixedly connected with the second heating rod main body 3, and the inner wall of the housing 1 is fixedly connected with a stabilizing plate 4 above the second heating rod main body 3, The stable plate has a double-layer structure, and the upper plate body and the lower plate body are supported by a plurality of densely arranged thermally expandable cylindrical materials, and through holes 5 with variable apertures are formed between the multiple cylinders. On the upper plate body A plurality of arc-shaped protrusions are also provided, and a plurality of cylinders close to the inner wall of the housing 1 are selected, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com