Method for reducing NOx by sintering

A technology for sintering mixture and quality, which is applied in the field of NOx reduction by sintering, and can solve the problems of limited reduction range and limited NOx reduction range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

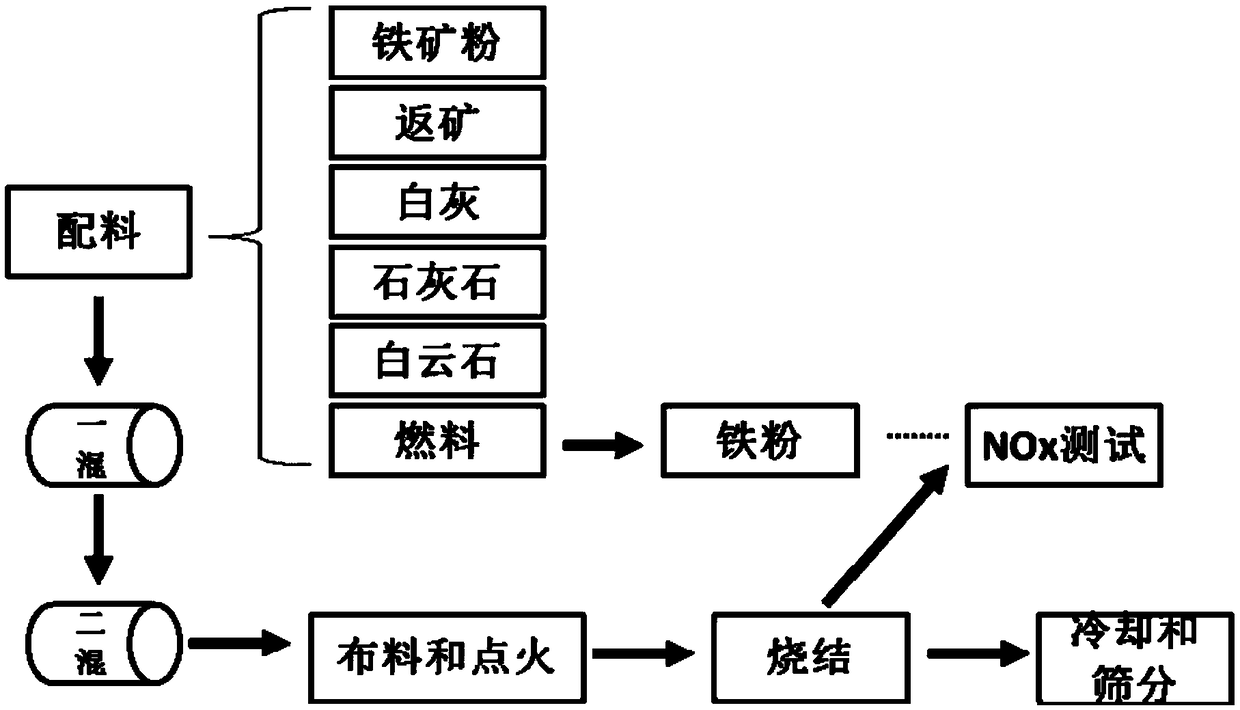

[0015] see figure 1 The embodiment of the present invention provides a method for reducing NOx by sintering, the steps of which include batching, mixing and granulation, distribution and ignition, sintering, cooling and screening after the sintering process, and NOx detection.

[0016] (1) Sintering mixture ingredients (the following proportions are all mass percentages):

[0017] The proportion of iron ore powder is 60%, the proportion of quicklime is 5%, the proportion of limestone is 0%, the proportion of dolomite is 7%, the proportion of coke powder is 2%, the proportion of iron powder is 10%, and the proportion of returned ore is 16%.

[0018] (2) Mixing and granulation: The selected sintering mixture components are mixed and wetted by a cylinder mixer and granulated by a cylinder mixer twice, and an appropriate amount of water is added for mixing and granulation.

[0019] The total amount of water added in the process of mixing wetting and mixing granulation is 7.0% of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com