Wire micro-arc oxidation automatic wire feeding device

A technology of micro-arc oxidation and wire material, which is applied in the direction of anodic oxidation, coating, surface reaction electrolytic coating, etc., can solve the problems of inapplicability to large-scale production, time-consuming and labor-intensive, etc., and achieve easy installation, save human resources, reduce Fracture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

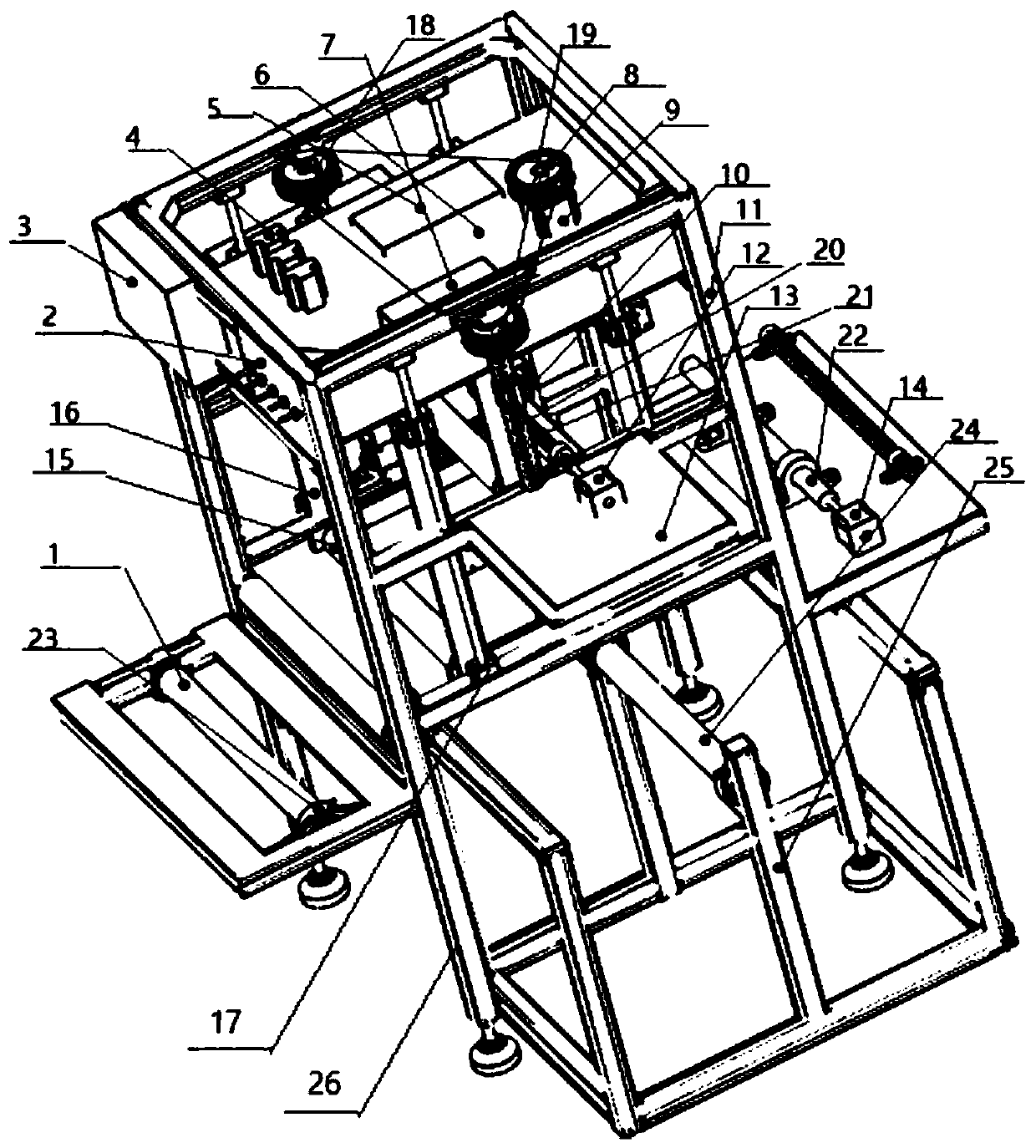

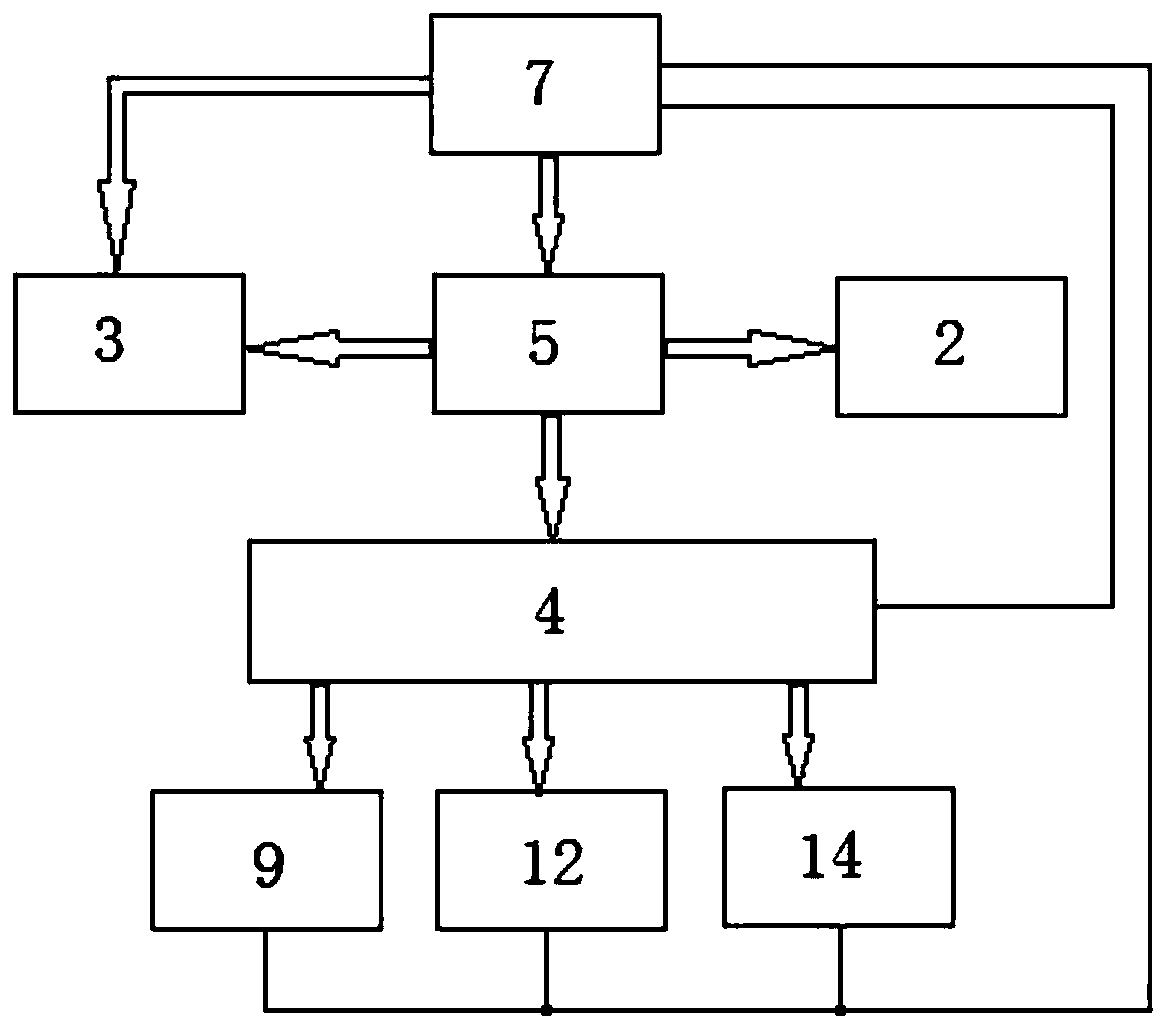

[0015] see figure 1 , an automatic wire-feeding device for micro-arc oxidation of wire materials, including a frame 26, the entire frame 26 includes four support rods, and the support rods are all made of polytetrafluoroethylene grooved rods 11. It ensures that the main control system on the device is in an insulated state, and the grooves on the support rod make the lines on the machine neatly arranged in the insulating protection bracket. The function of this component is to facilitate the wiring space for the electric control system while providing insulation. And, this member can be replaced by an insulating bracket and a wire box.

[0016] The stainless steel wire feeding shaft 1 is fixed on the lower left side of the frame 26 through the bearing support 23, a toggle switch 2 and a display screen 3 are installed on the upper left side of the frame 26, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com