Construction method of whirling well hanging-upside furnace wall deep foundation pit support

A technology for deep foundation pit support and construction method, which is applied to the construction field of deep foundation pit support with upside-down retaining walls of swirl wells, can solve the problems of low construction efficiency, long construction period, high labor intensity, etc., and achieves improved construction efficiency, The effect of shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

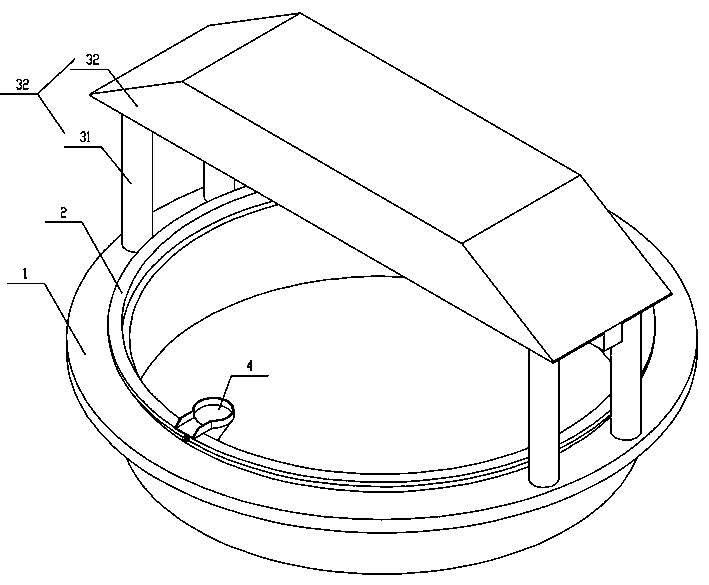

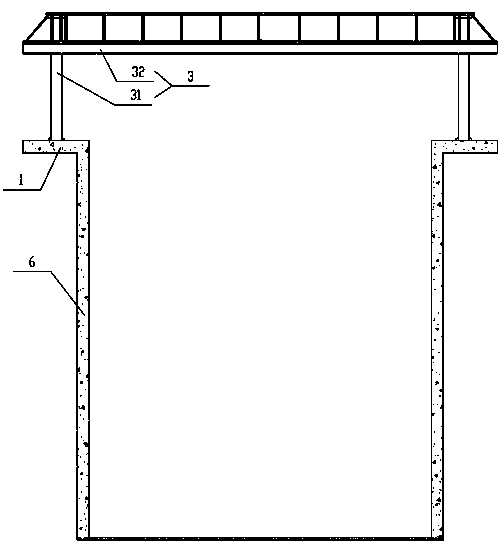

[0026] see figure 1 , figure 2 , Figure 6 , this embodiment is a construction method for deep foundation pit support of a swirl well with a diameter of 14.1m and a depth of 14.5m. The design parameters are as follows after calculation: the thickness of the retaining wall is 0.45m, and the upside-down retaining wall is divided into 9 layers, from -0.6m to -15.1m. The height of each layer from the first layer to the eighth layer is 1.7m, the height of the last layer is 0.9m, and the height of the bottom layer of the swirling well is 0.8m. The specific steps are as follows:

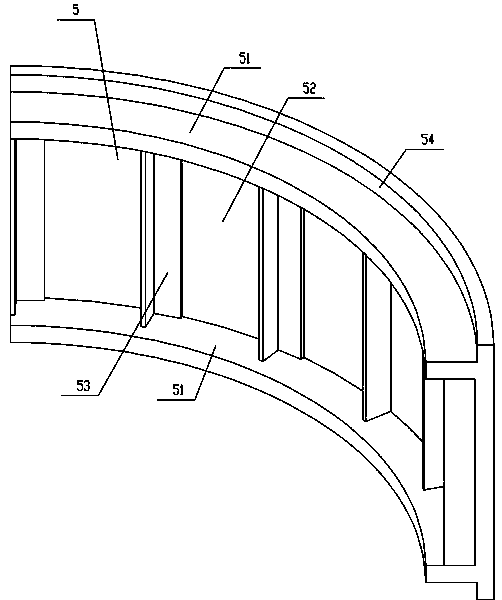

[0027] 1) Measure and set-out positioning, and make steel molds: Make steel molds according to the diameter of the swirling well 6. The steel molds are composed of 29 sections of retaining formwork 5, and each section of retaining formwork 5 includes two curved flat plates 51 with a radius of 7.05m ( The arc length is 1.5m), and a section of vertical arc-shaped coil 52 is welded between two arc-shaped f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com