Water fuel engine

A technology of engine and water fuel, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of accelerating energy consumption and damaging the environment, and achieve the effects of reducing the increase of frictional resistance, reducing environmental pollution, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

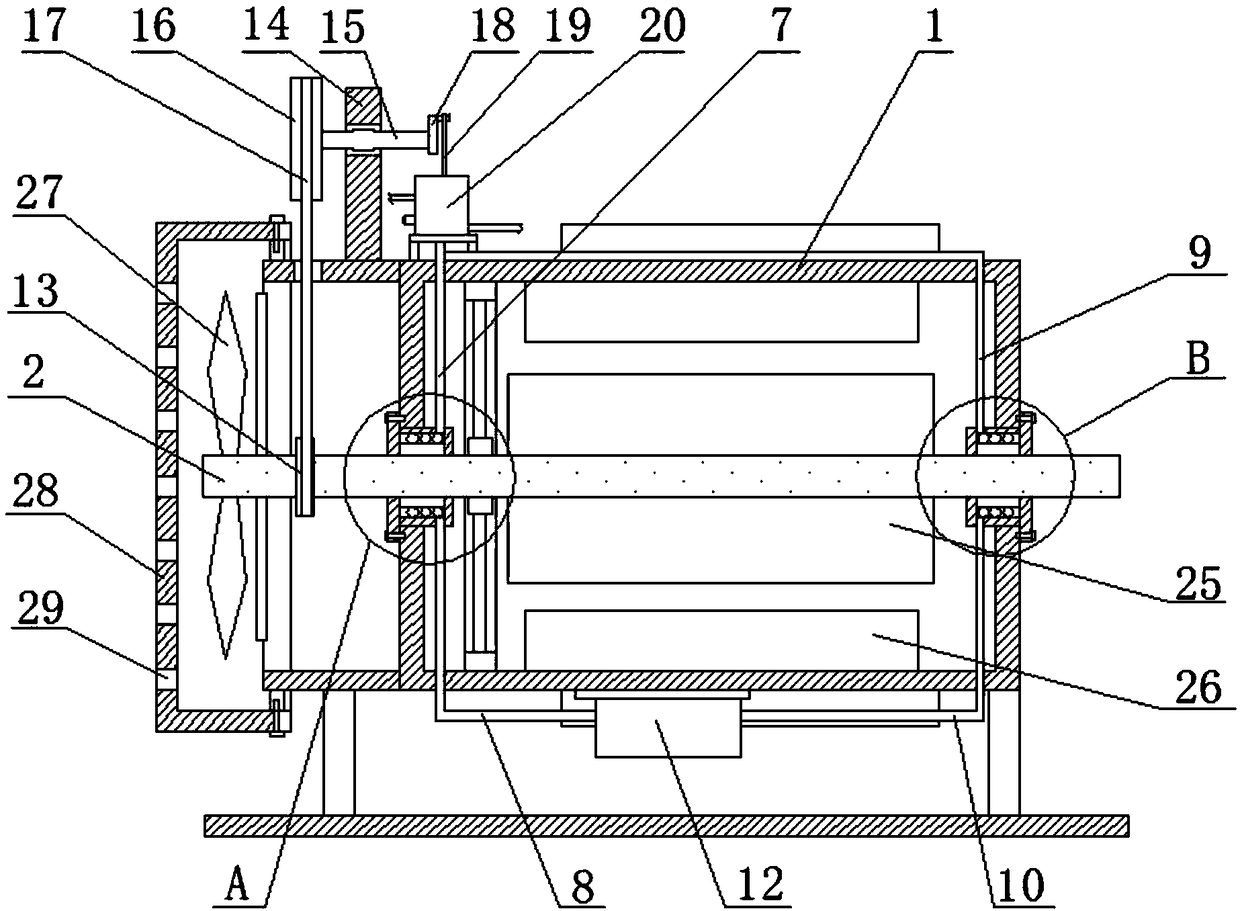

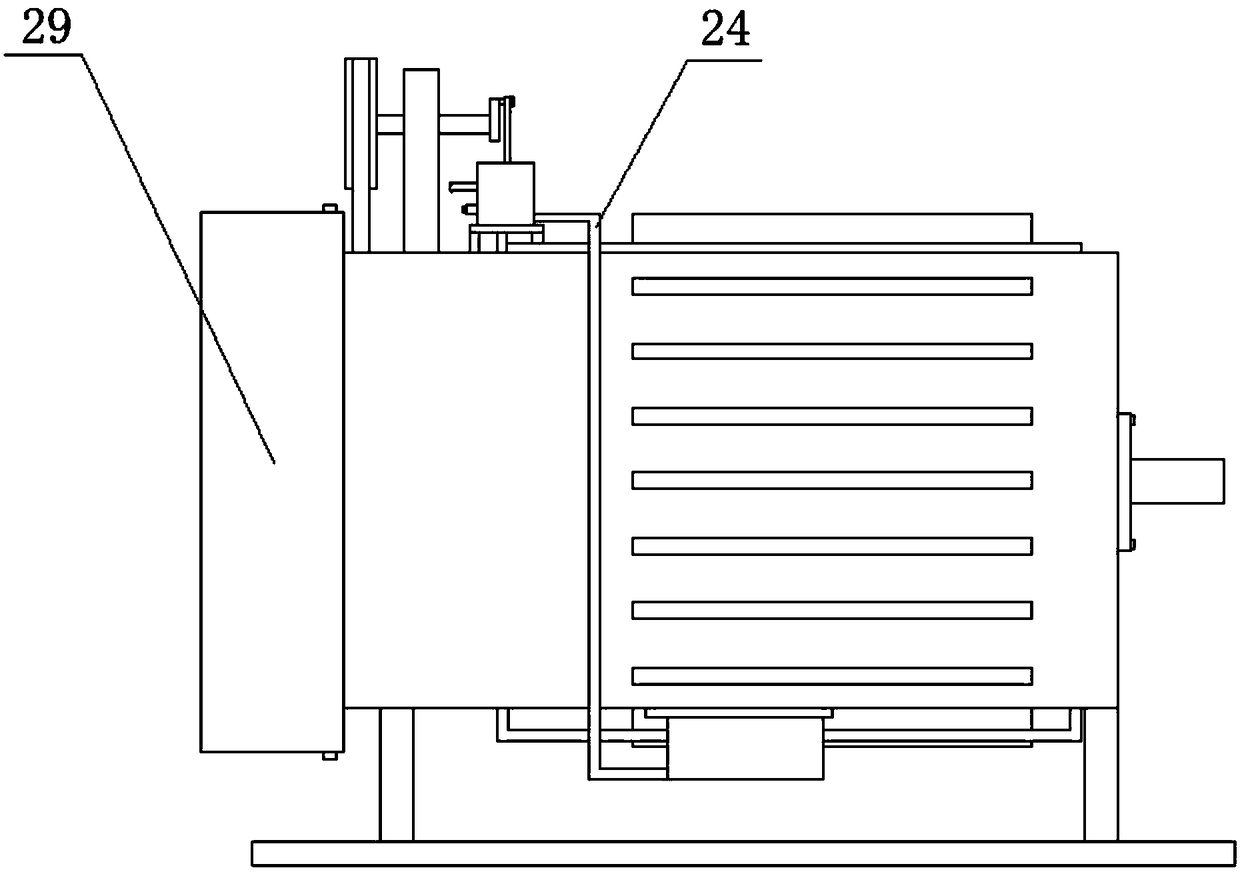

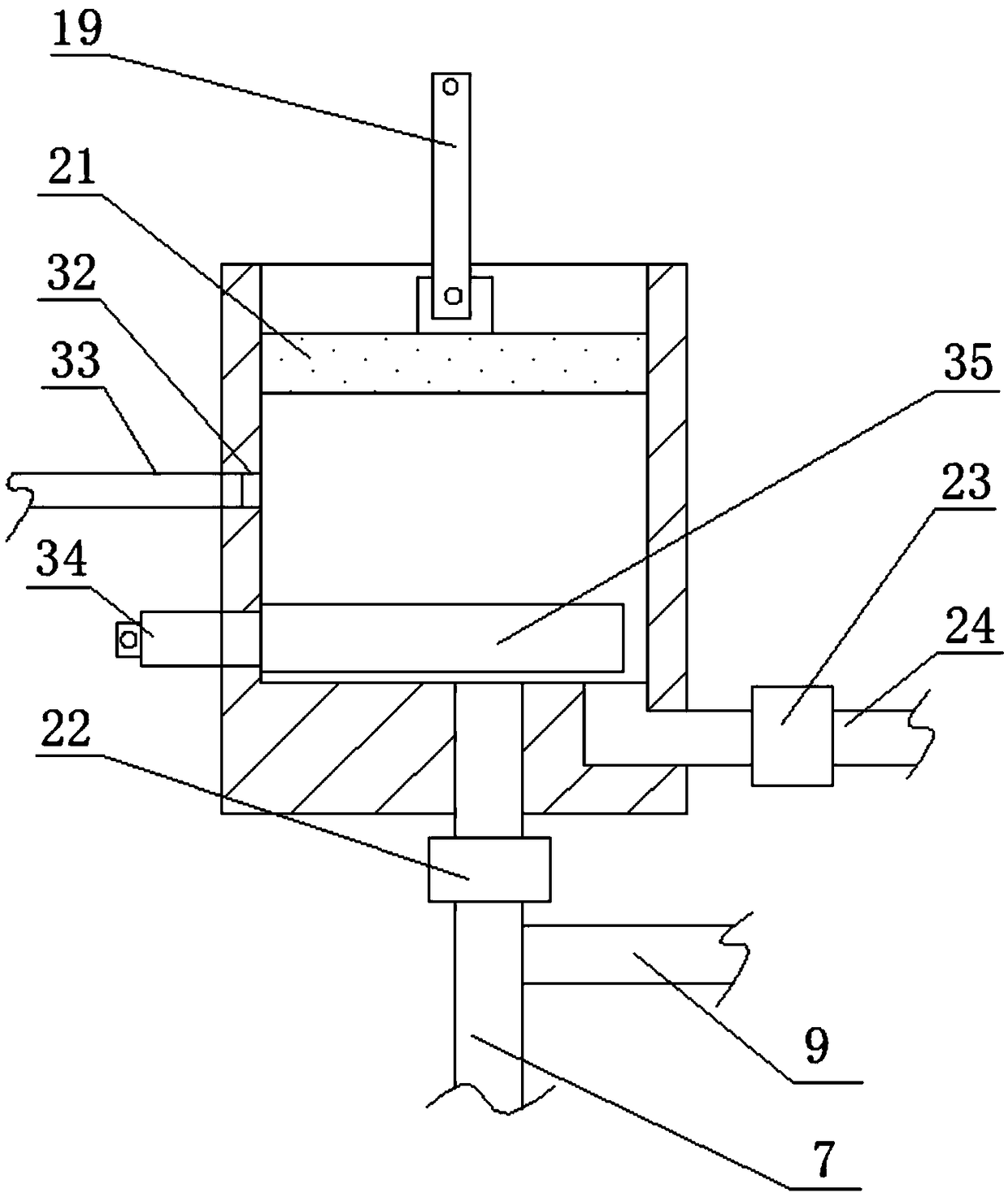

[0025] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 : a water fuel engine, comprising a casing 1, the two sides of the casing 1 are respectively provided with a first bearing accommodating groove 3 and a second bearing accommodating groove 5, one side of the casing 1 is respectively provided with A rotating shaft 2 of a bearing receiving groove 3 and a second bearing receiving groove 5, the outer side of the rotating shaft 2 is sleeved with a first bearing 4 and a second bearing 6, and the first bearing 4 is located in the first bearing receiving groove 3, The second bearing 6 is located in the second bearing accommodating groove 5, the outer sides of the first bearing accommodating groove 3 and the second bearing accommodating groove 5 are flange-connected with a gland 11, and the top of the casing 1 is fixed by welding There is a cylinder body 20, a piston 21 is movably connected in the cylinder body 20, the top of the piston 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com