Coating interface bonding strength detection method and equipment

A technology of interface bonding strength and detection method, applied in the direction of measuring devices, instruments, mechanical devices, etc., can solve problems such as deficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

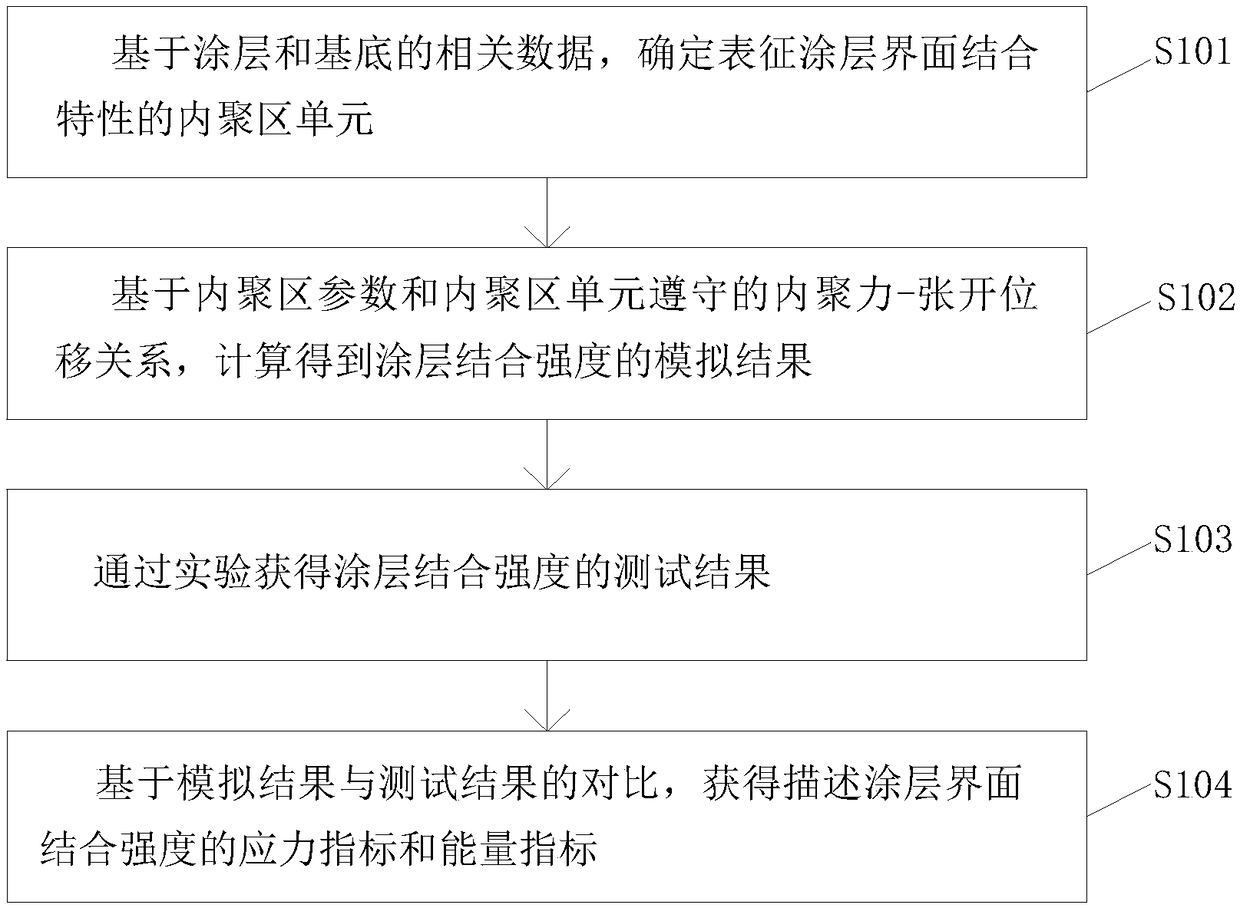

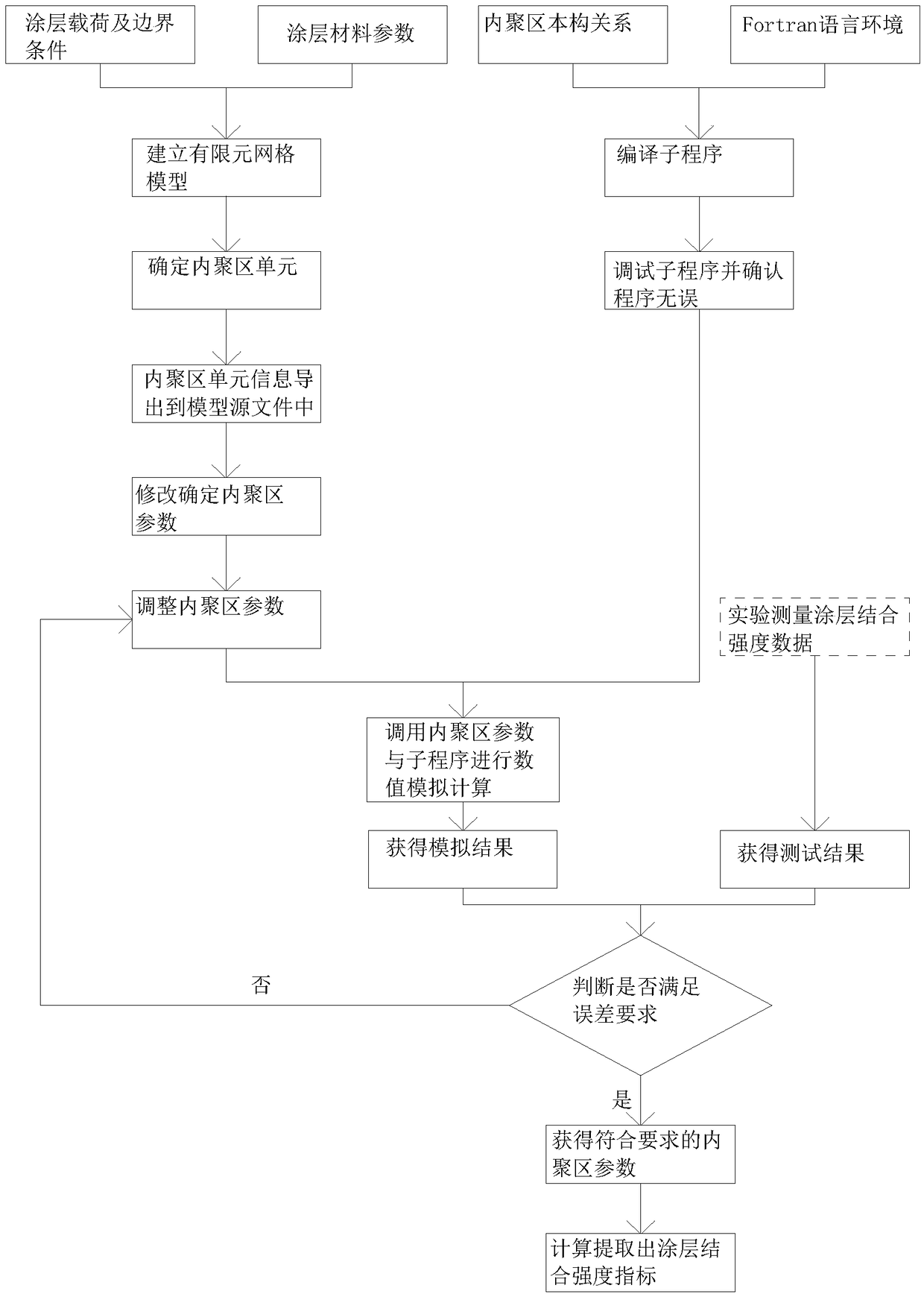

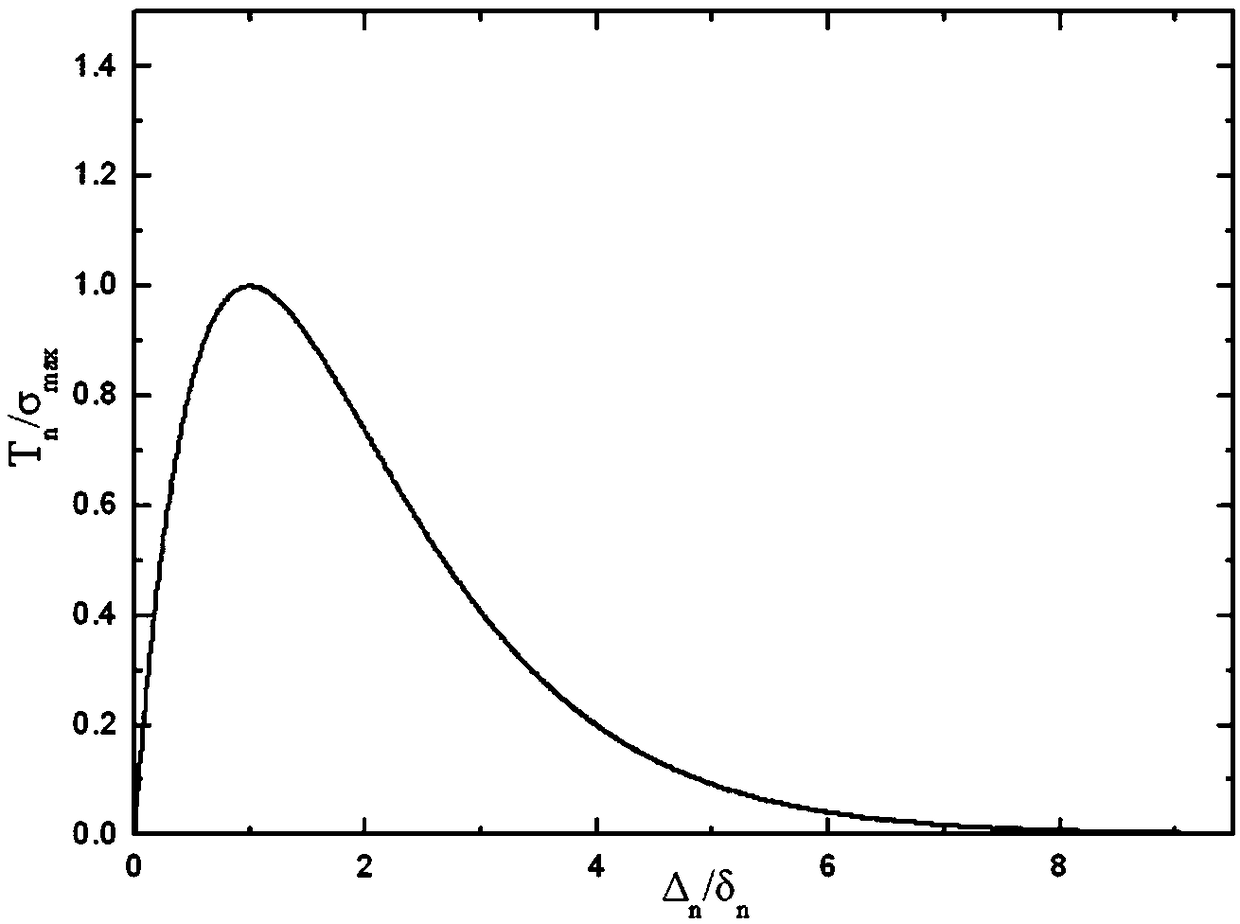

[0051]In view of the shortcomings of the current means of obtaining the characterization index of coating bonding strength, the present application proposes a more suitable analysis method based on the thermodynamic energy balance viewpoint of the Cohesive Zone Model (CZM, Cohesive Zone Model). The finite element simulation practice of thin film delamination failure shows that it can describe the whole process of interface crack initiation and propagation along the interface, and the given interface bonding performance index depends only on the characteristics of the coating material itself, and has nothing to do with the sample geometry. According to the parameter composition of the cohesive zone model, it can quantitativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com