High-precision installation and adjustment method for total-reflection off-axis collimating optical system

A technology of collimating optics and adjustment methods, applied in optics, optical components, installation, etc., can solve problems such as angle control and space reference establishment, difficulties, and repeated iterations in the adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

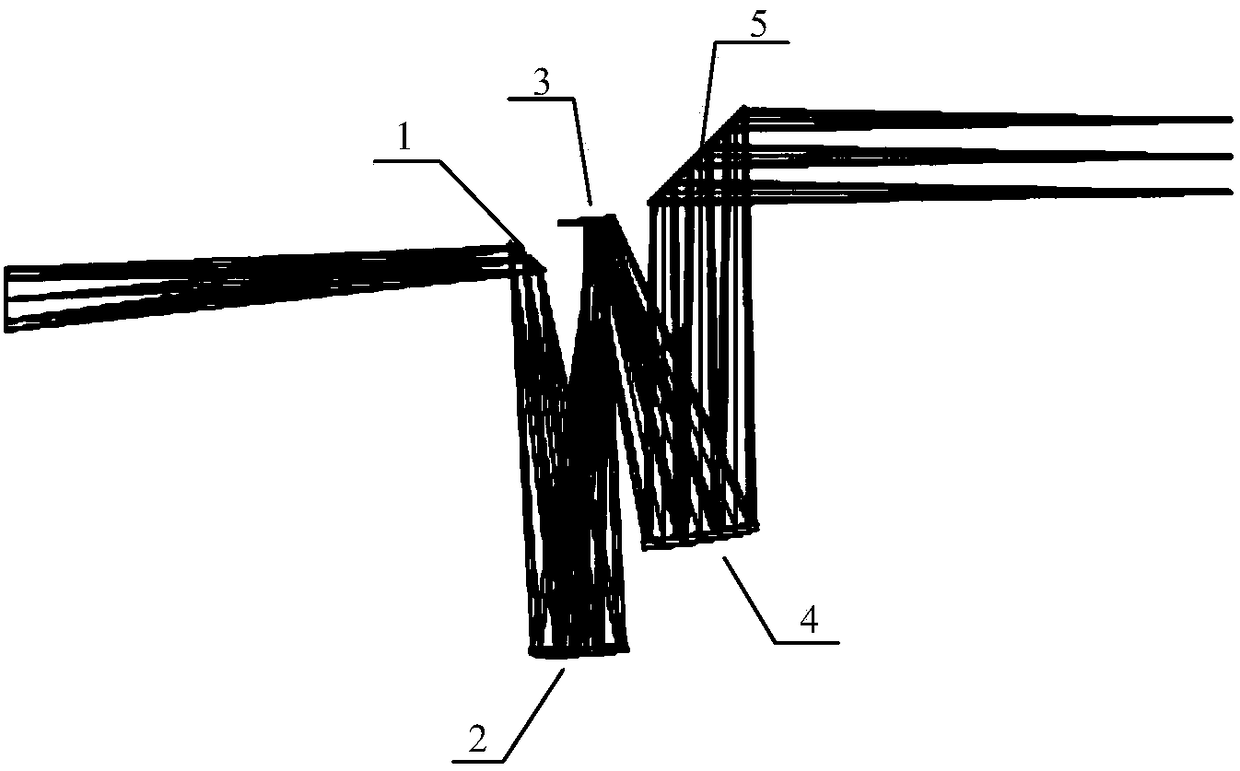

[0028] The specific steps of a high-precision adjustment method for a fully inverted off-axis collimation optical system are as follows:

[0029] The first step is the establishment of optical reference and tilt transformation

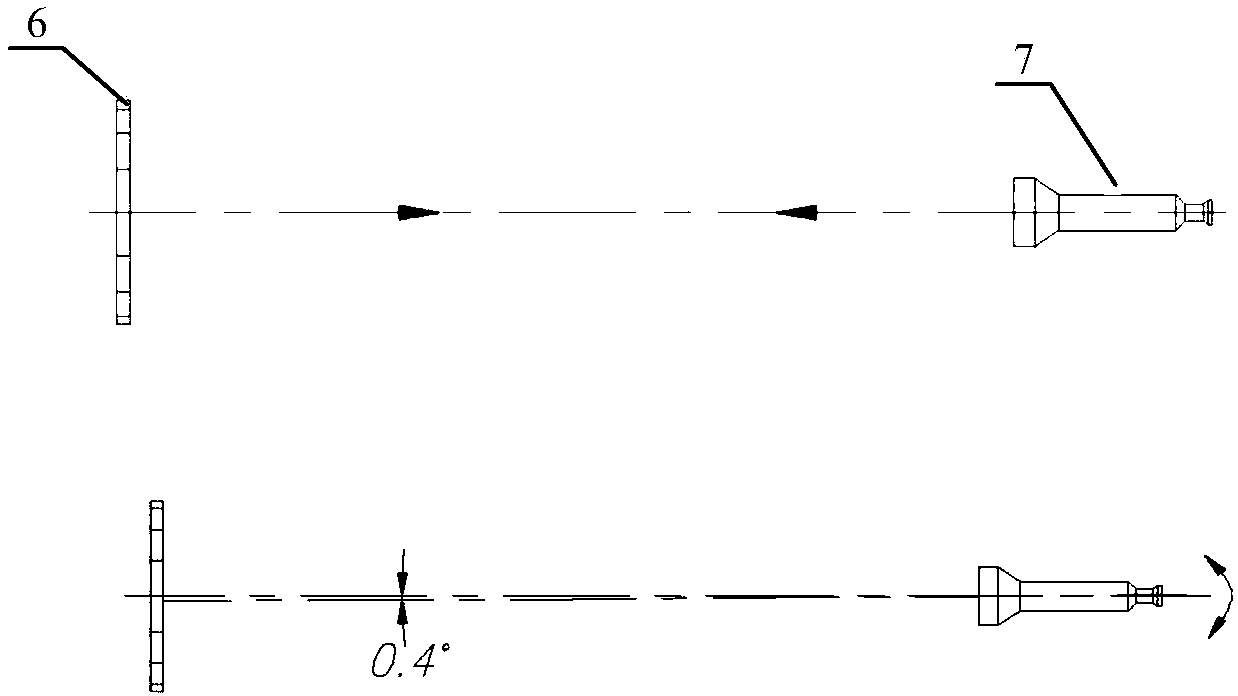

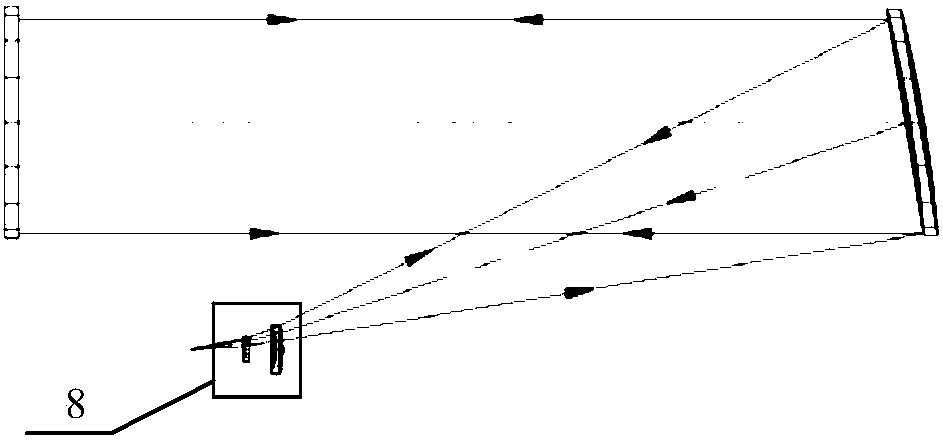

[0030] First, use a height gauge to determine the center height of the optical axis, and unify the center heights of all mirrors; if the primary mirror 4 is tilted by 0.4°, the subsequent secondary mirror 3 and third mirror 2 are all tilted by 0.4°. In order to ensure the unity of the mechanical axis and the optical axis of the system, and that the outgoing beam is incident on the instrument under test along the mechanical axis, after the horizontal optical reference is established, the standard flat mirror 6 is reversely rotated by 0.4° to compensate for the tilt of the field of view of the whole machine.

[0031] The second step is the installation and calibration of the primary mirror 4

[0032] The installation and calibration of the main mirror 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com