A mining belt longitudinal tearing detection device and method

A detection method and technology of detection device, which are applied in the fields of instruments, character and pattern recognition, computer parts, etc., can solve the problems of relatively high requirements for acquisition, transmission, and computing power, field application in difficult coal mines, and large hardware volume, etc. cost, improve algorithm performance and efficiency, and reduce equipment size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

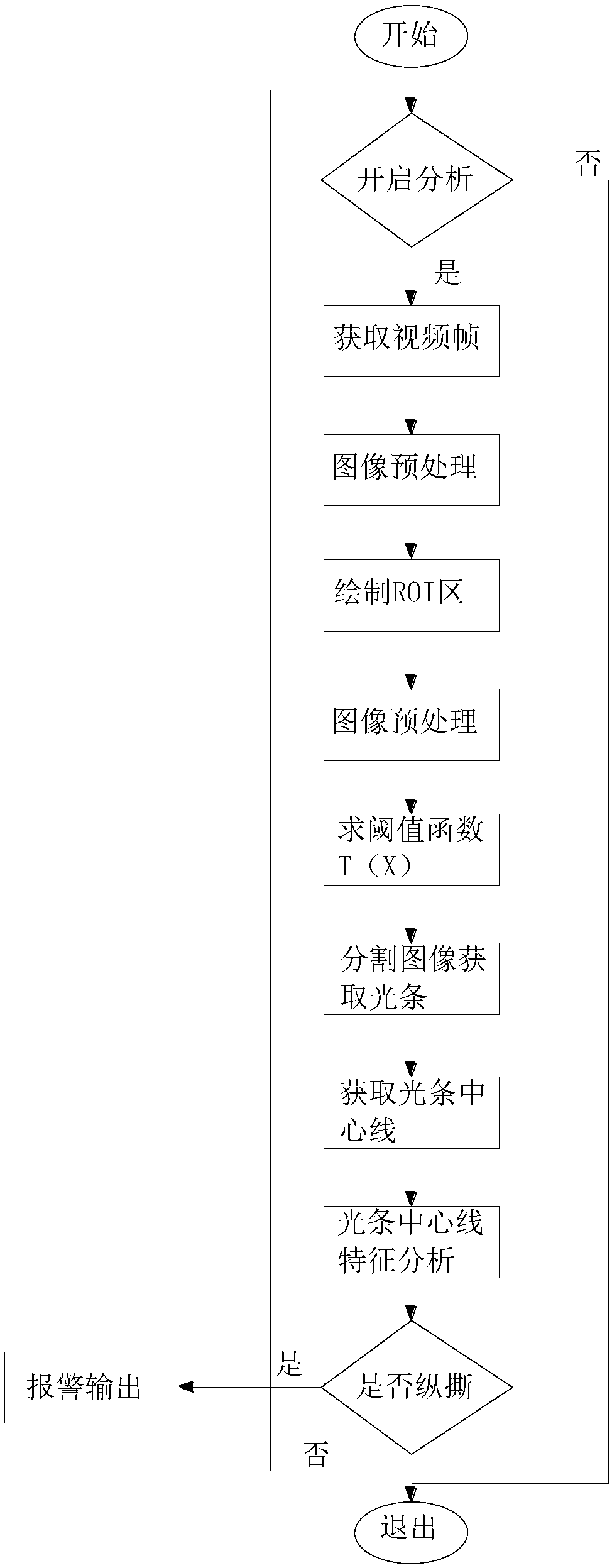

[0061]The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

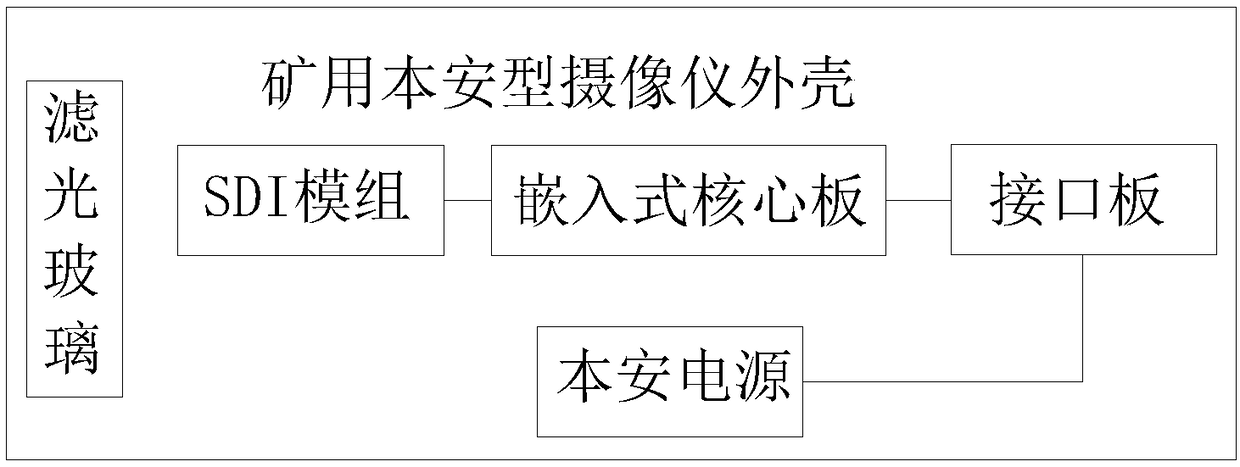

[0062] The invention provides a mine belt longitudinal tear detection device, which includes a mine linear laser emitter for emitting a linear laser to the mine belt and a mine visual sensor platform for capturing reflected light and converting it into a video image.

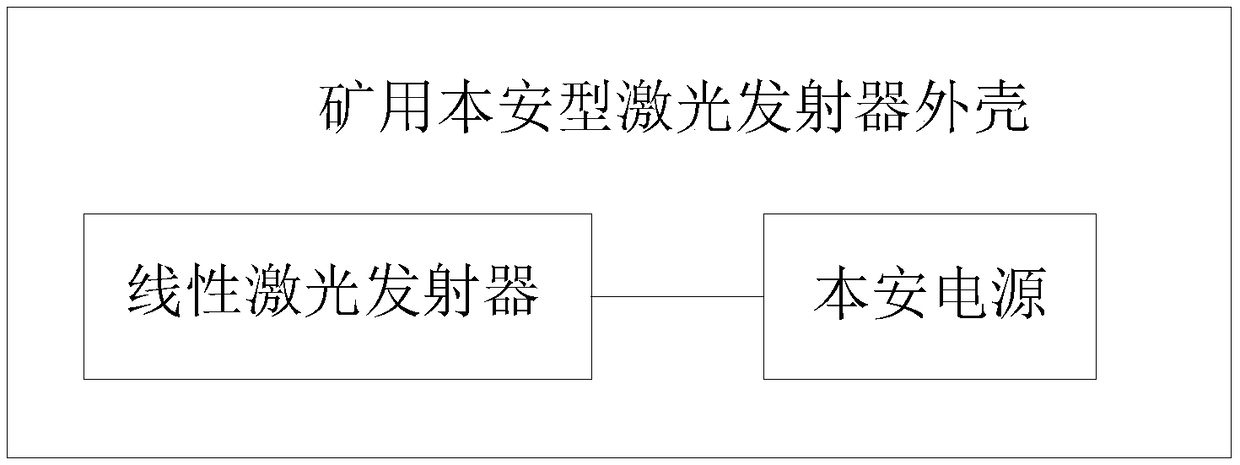

[0063] Such as figure 1 As shown, the mine linear laser transmitter includes a mine intrinsically safe laser transmitter shell and a linear laser transmitter and an intrinsically safe power supply arranged in the mine intrinsically safe laser transmitter shell, and the intrinsically safe power supply and The electrical connection of the linear laser transmitter adopts the mine-used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com