Automatic dismounting type power battery box system

A power battery, automatic disassembly and assembly technology, applied in the field of new energy vehicles and energy storage power stations, can solve problems such as inability to control accidents in a timely and effective manner, inability to quickly isolate fault sources, and low degree of automation, so as to avoid further expansion of accidents, The effect of improving safety and reliability and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

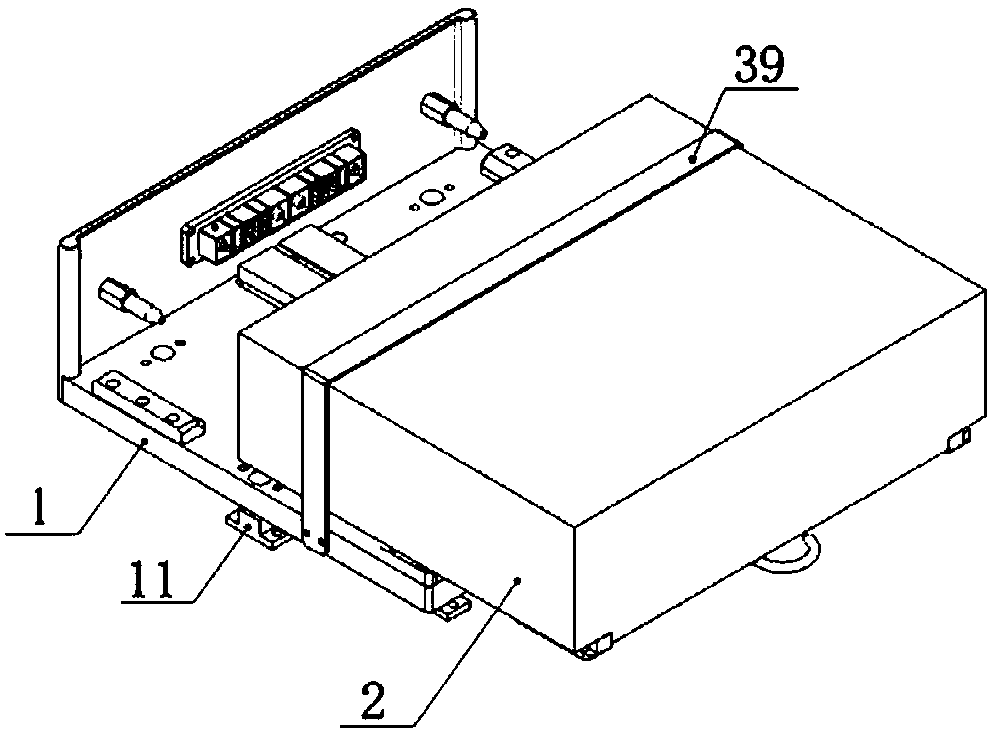

[0044] In this example, if figure 1 As shown, an automatic disassembly and assembly power battery box system includes a base 1 and a battery box 2 .

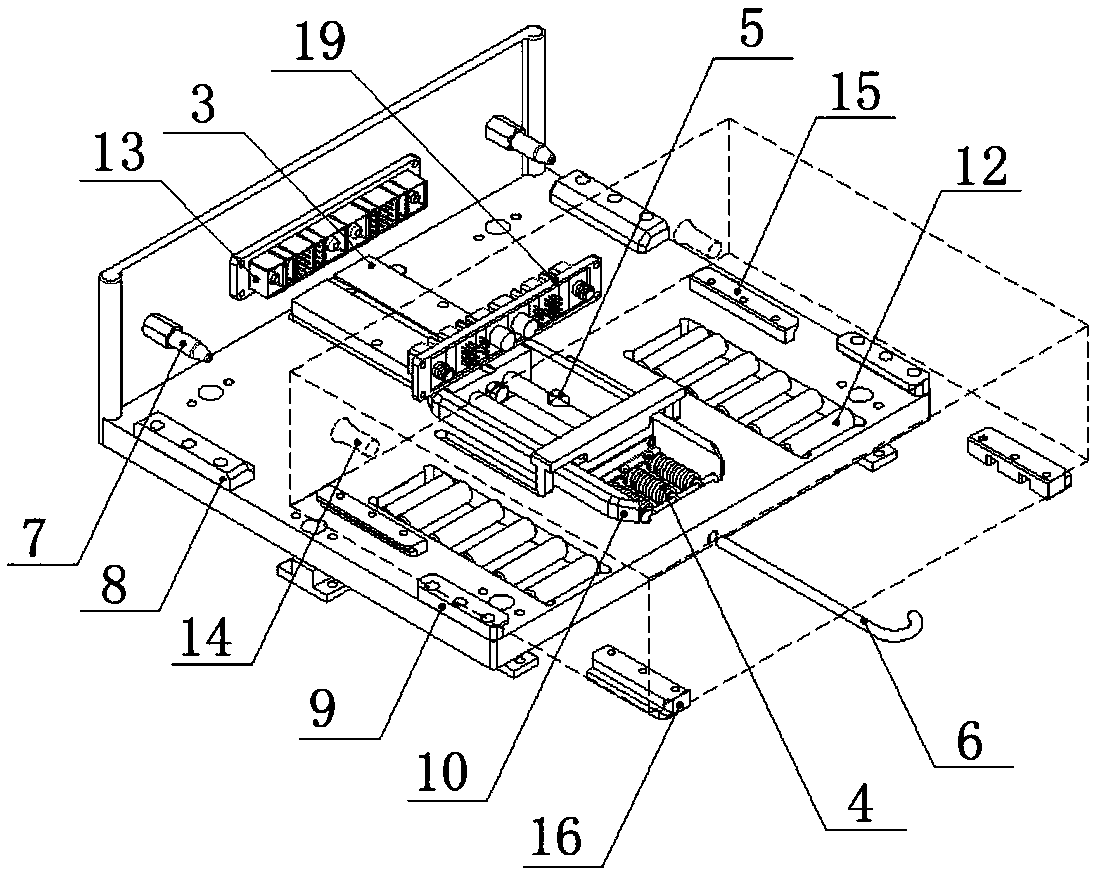

[0045] In this example, if figure 2As shown, the separation device 4, the locking device 5, the unlocking device 6, the positioning pin 7, the base primary guide rail (10), the secondary guide rail (8, 9), the base elastic member 11, the roller 12 and the connection are installed on the base 1. Device socket 13, its effect is to carry battery box 2. The battery box 2 is provided with positioning pin holes 14 , battery box guide rails ( 15 , 16 ), guide grooves 17 , power triggers 18 and connector plugs 19 .

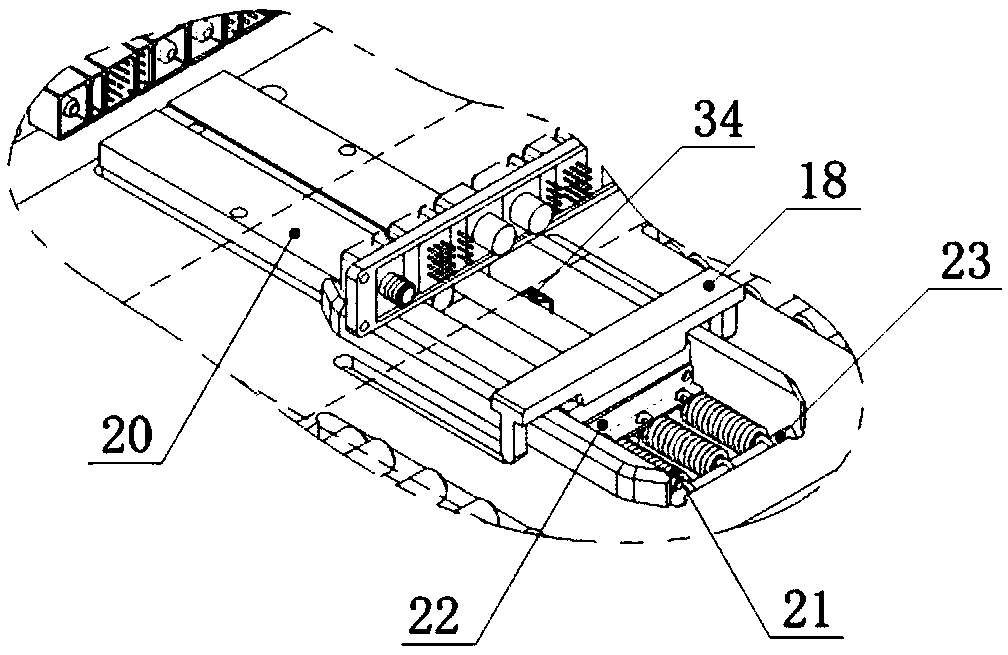

[0046] In this embodiment, the receiving device 3 includes a vehicle-mounted power source 20 and a power trigger 18. The vehicle-mounted power source 20 adopts an electric drive device, and the automatic storage and separation of the battery box 2 is realized through the electric drive device.

[0047] In this embodimen...

Embodiment 2

[0060] In this embodiment, an automatically disassembled power battery box system includes a base 1 and a battery box 2 .

[0061] In this embodiment, the base 1 is used to install the separation device 4, the locking device 5, the unlocking device 6, the positioning pin 7, the primary guide rails (8, 9) of the base, the secondary guide rails 10 of the base, the elastic parts 11 of the base, and the rollers 12 and connector socket 13, the battery case 2 is provided with the positioning pin hole 14 that cooperates with the positioning pin of the base 1, the guide groove 17 that cooperates with the primary guide rail of the base, and the guide rail (15, 9) that cooperates with the secondary guide rail (8, 9). 16), a power trigger 18 and a connector plug 19 matched with the connector socket 13.

[0062] In this embodiment, the absorbing device 3 includes a vehicle-mounted power source 20 and a power trigger 18, the vehicle-mounted power source 20 adopts a pneumatic cylinder, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com