Electric resistance welded stainless steel clad steel pipe and manufacturing method thereof

A technology of composite steel pipe and manufacturing method, which is applied in electric resistance welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of not being able to exert the required performance and difficult to have both mechanical properties of the composite steel pipe and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] A stainless steel clad steel strip consisting of an austenitic stainless steel sandwich material with a thickness of 2mm and a low-carbon low-alloy steel base material with a thickness of 5mm is prepared, and the composition of the above-mentioned austenitic stainless steel contains C: 0.015% in mass % , Si: 0.76%, Mn: 1.06%, Ni: 12.2%, Cr: 17.4%, Cu: 0.24%, Mo: 2.32%, the rest is composed of Fe and unavoidable impurities, the composition of the above-mentioned low-carbon low-alloy steel The composition contains C: 0.04%, Si: 0.2%, Mn: 1.60%, V: 0.04%, Nb: 0.05%, Ti: 0.01% in mass %, and the rest is composed of Fe and unavoidable impurities.

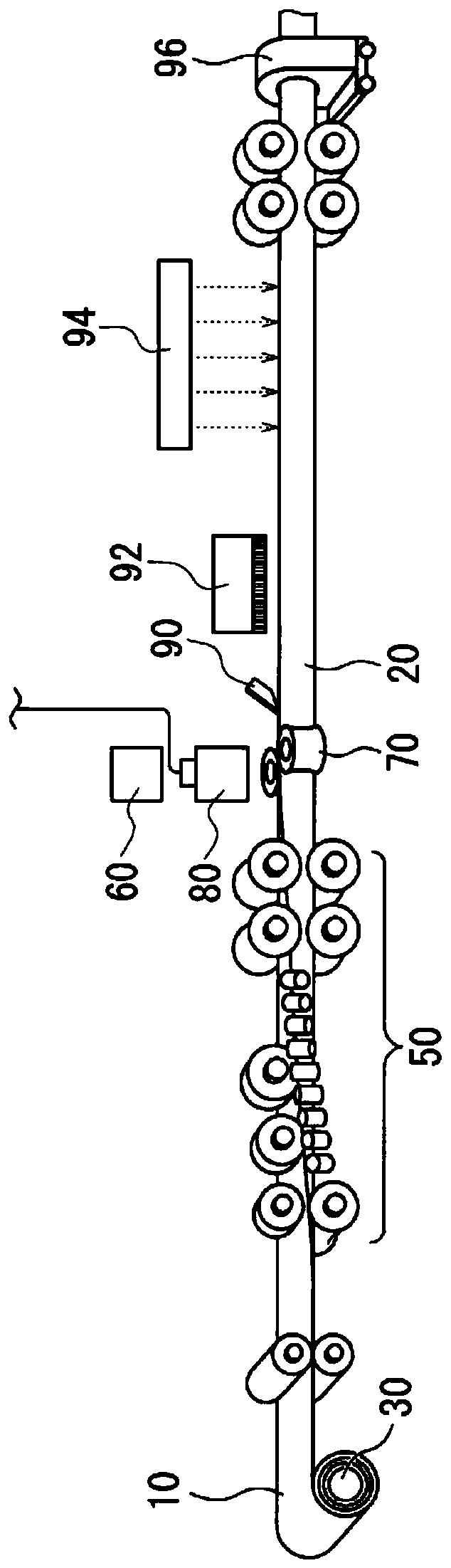

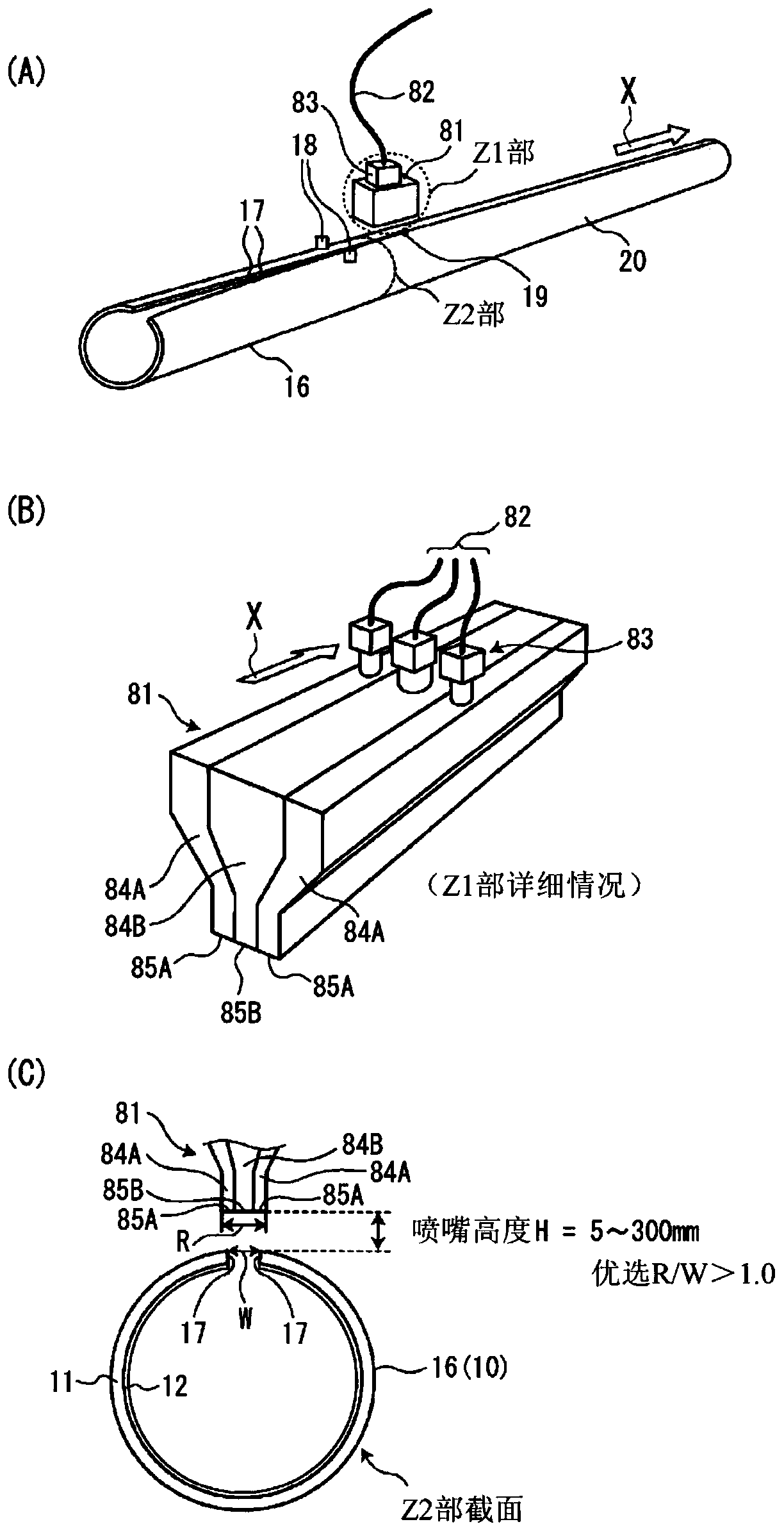

[0111] use figure 1 The electric resistance welded steel pipe manufacturing equipment shown in , uses the prepared stainless steel clad steel strip as the blank material, the base metal as the outer layer, and the interlayer material as the inner layer, and manufactures resistance welded stainless steel clad steel strips with an ...

Embodiment 2

[0120] An interlayer material of austenitic stainless steel having a thickness of 2 mm and having the composition shown in Table 2 (the remainder being Fe and unavoidable impurities) and a stainless steel consisting of a base material of low-carbon low-alloy steel of 5 mm in thickness were prepared Composite steel strip, the composition of the above-mentioned low-carbon low-alloy steel contains C: 0.04%, Si: 0.2%, Mn: 1.60%, V: 0.04%, Nb: 0.05%, Ti: 0.01%, and the rest Consists of Fe and unavoidable impurities.

[0121] use figure 1 The electric resistance welded steel pipe manufacturing equipment shown in , uses the prepared stainless steel clad steel strip as the blank material, uses the base material as the outer surface side of the pipe, and uses the interlayer material as the inner surface side of the pipe to manufacture electric resistance welded stainless steel clad steel pipe with an outer diameter of 300 mm. Used for gas shielding of the welded part during resistanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com