A torsion bar and its processing method

A processing technology and torsion bar technology, applied in the field of torsion bar and its processing technology, can solve problems such as difficulty in meeting drinking water standards, threats to human health and life, low influent turbidity, etc., and meet the needs of long-term stable operating conditions , excellent plasticity, performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

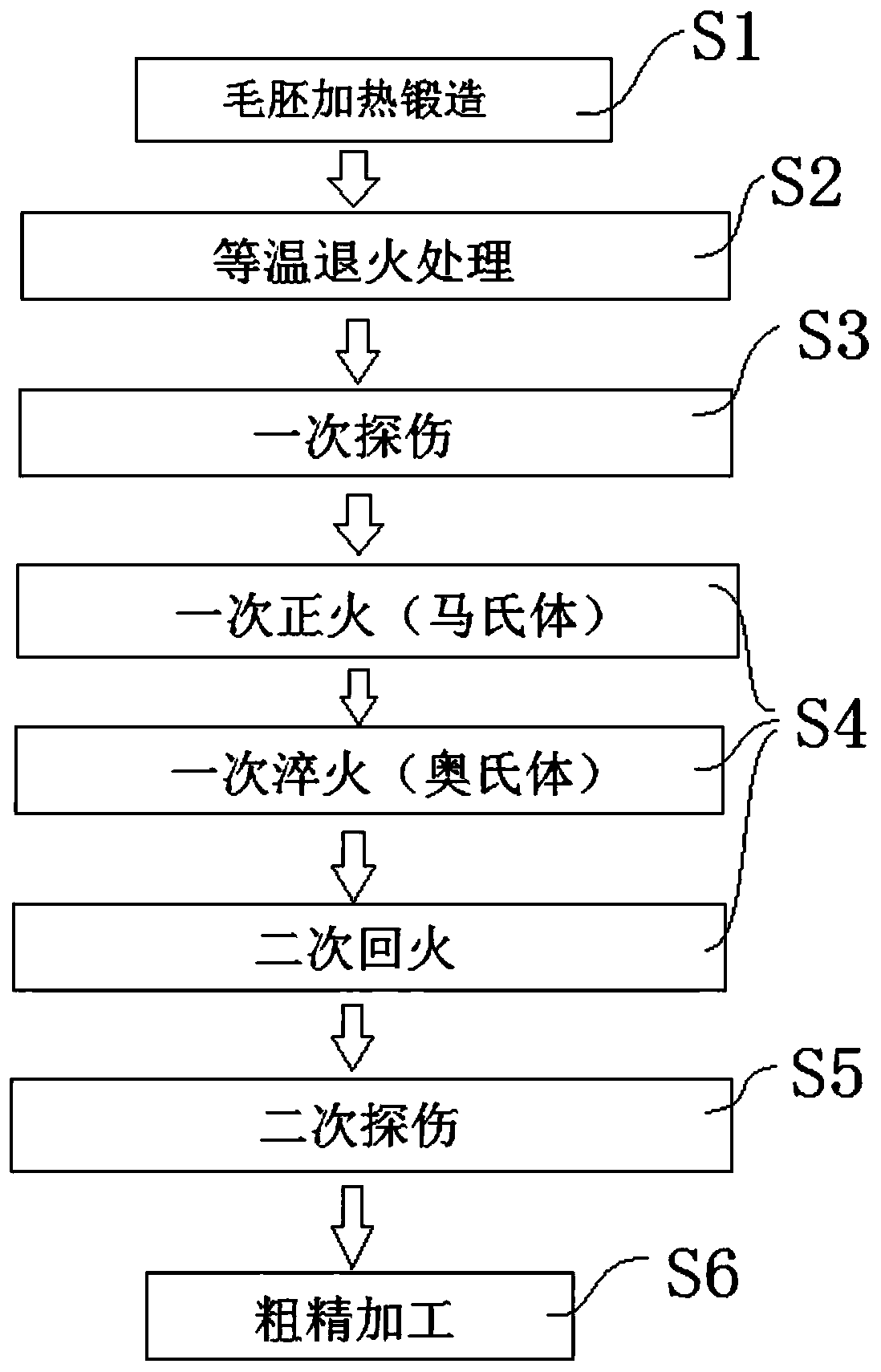

[0056] combine Figure 5 , 6and 7, the present embodiment provides a torsion bar 1, including a vibrating tray 12, a connecting rod 11 and an end plate 13 integrally provided. The outer periphery of the vibrating tray 12 is evenly provided with a number of membrane barrel connecting holes 121, which are connected to the filter assembly 2 by flanged bolts. The central shaft 7 is fixedly fitted with threads, and the outer periphery of the end plate 13 is evenly provided with a number of through holes 131, which are connected with the vibration platform 4 of the water treatment equipment through bolts 3.

[0057] The raw carbon steel composition of this torsion bar includes:

[0058] 0.38% carbon by weight;

[0059] 0.01% by weight phosphorus;

[0060] 0.65% manganese by weight;

[0061] 1.52% silicon by weight;

[0062] 0.75% chromium by weight;

[0063] 1.65% nickel by weight;

[0064] 0.30% molybdenum by weight;

[0065] 0.25% copper by weight;

[0066] 0.05% vanadiu...

Embodiment 2

[0081] This embodiment provides a torsion bar with the same structure as that of Embodiment 1.

[0082] The raw carbon steel composition of this torsion bar includes:

[0083] 0.43% carbon by weight;

[0084] 0.02% by weight phosphorus;

[0085] 0.90% manganese by weight;

[0086] 1.80% silicon by weight;

[0087] 0.95% chromium by weight;

[0088] 2.00% nickel by weight;

[0089] 0.50% molybdenum by weight;

[0090] 0.35% copper by weight;

[0091] 0.12% vanadium by weight;

[0092] Calcium at a weight ratio of 0.01; and

[0093] The other components are iron and extremely small amounts of impurities (such as: oxygen, sulfur, nitrogen);

[0094] The torsion bar processing method includes:

[0095] Step S1: First, after heating the forging temperature of the blank to the temperature range of 800°C-840°C, forging is carried out.

[0096] Step S2: After the previous step is completed, perform isothermal annealing;

[0097] Step S3: Carry out flaw detection afterwards...

Embodiment 3

[0106] This embodiment provides a torsion bar with the same structure as Embodiment 1 and Embodiment 2.

[0107] The raw carbon steel composition of this torsion bar includes:

[0108] 0.40% carbon by weight;

[0109] 0.015% by weight phosphorus;

[0110] 0.75% manganese by weight;

[0111] 1.65% silicon by weight;

[0112] 0.82% chromium by weight;

[0113] 1.85% nickel by weight;

[0114] 0.42% molybdenum by weight;

[0115] 0.32% copper by weight;

[0116] 0.08% vanadium by weight;

[0117] Calcium at a weight ratio of 0.012; and

[0118] The other components are iron and extremely small amounts of impurities (such as: oxygen, sulfur, nitrogen);

[0119] The torsion bar processing method includes:

[0120] Step S1: First, after heating the forging temperature of the blank to the temperature range of 800°C-830°C, forging is carried out.

[0121] Step S2: After the previous step is completed, perform isothermal annealing;

[0122] Step S3: Carry out flaw detection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com