Cutting insert and replaceable cutting edge rotary cutting tool

A technology of cutting inserts and inserts, applied in milling cutting inserts, manufacturing tools, milling cutters, etc., can solve the problems of uneven properties of the machined surface and uniform machining accuracy of the unmachined surface, and achieve the effect of uniform properties and excellent machining surface accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

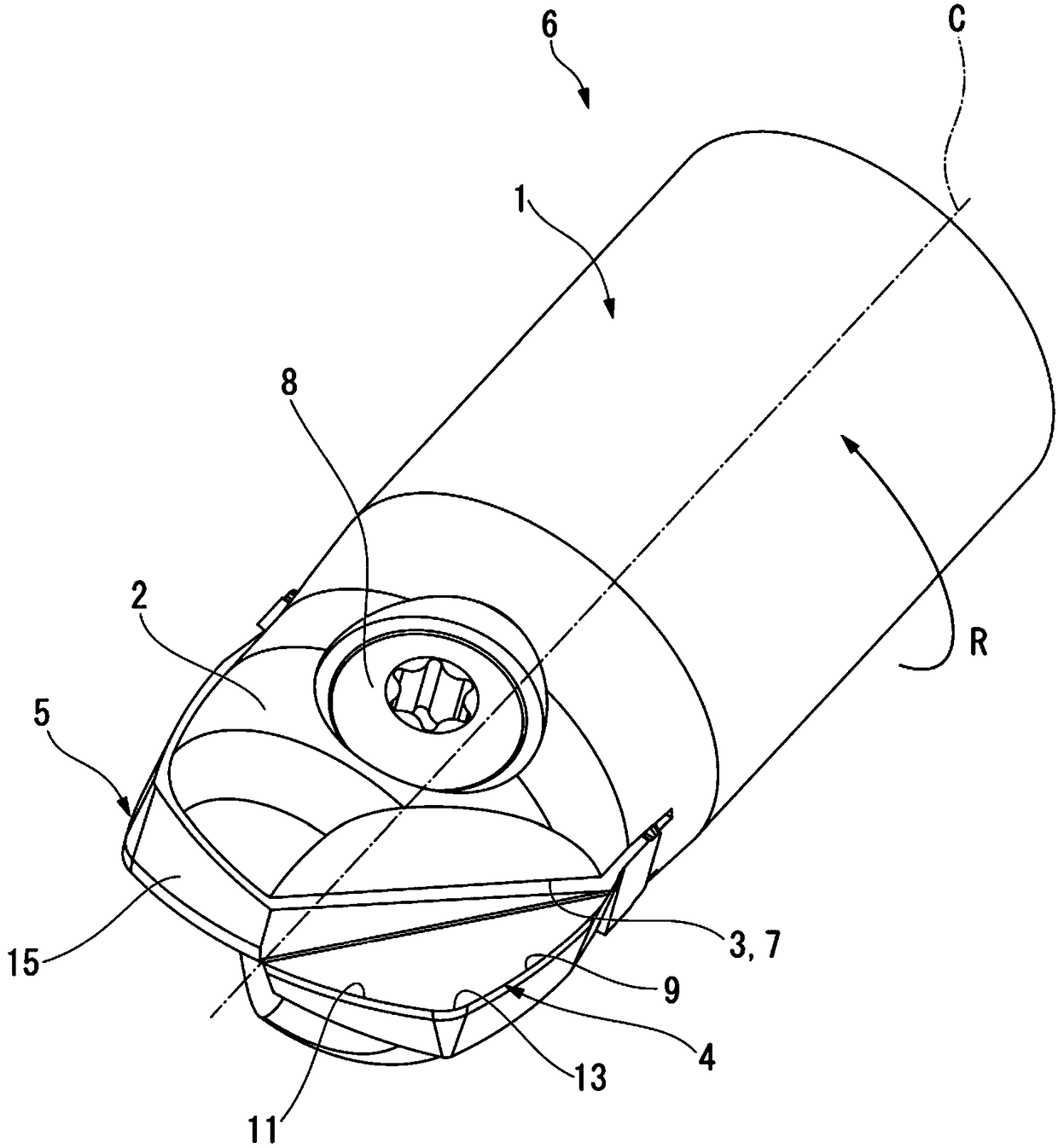

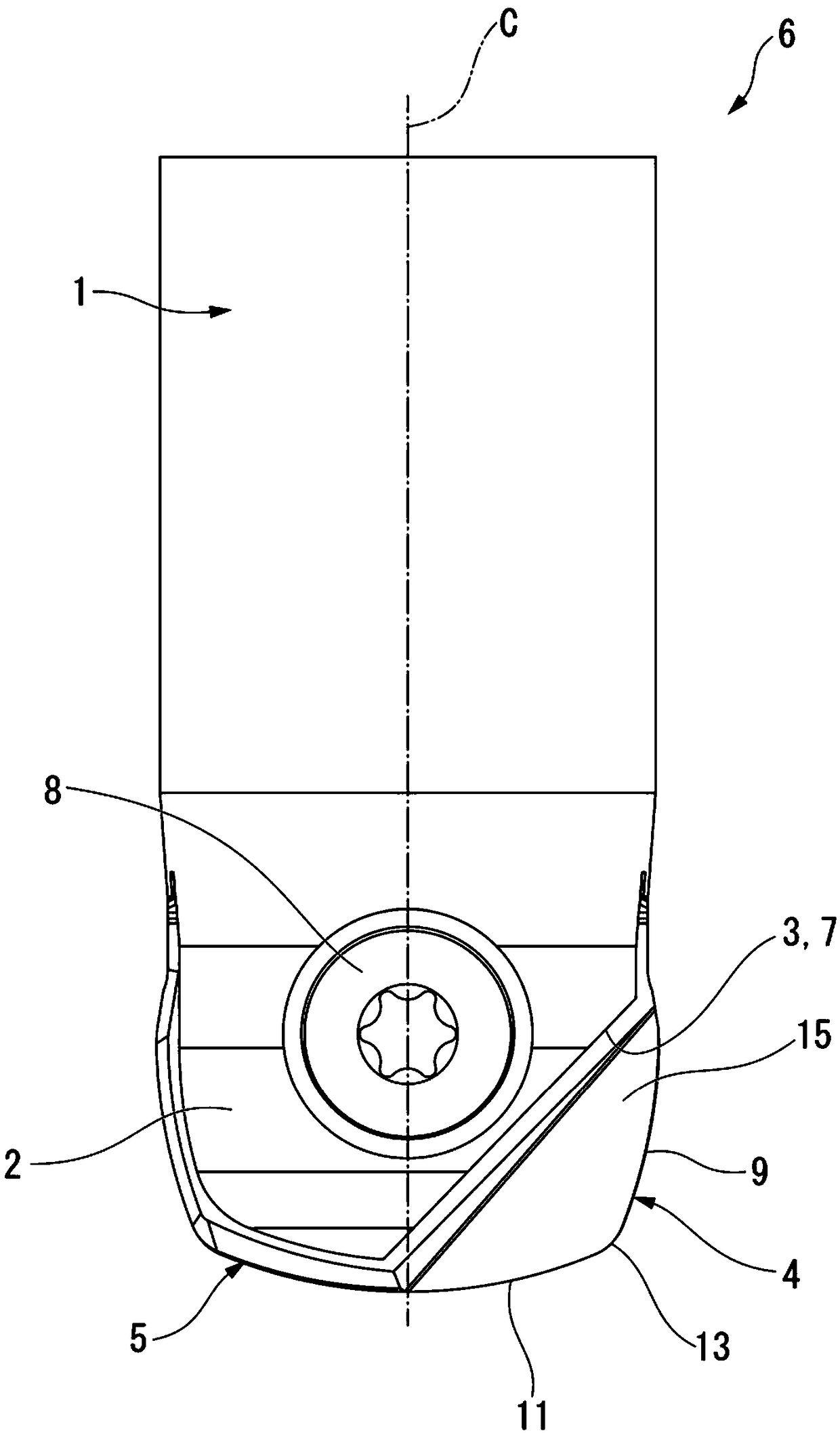

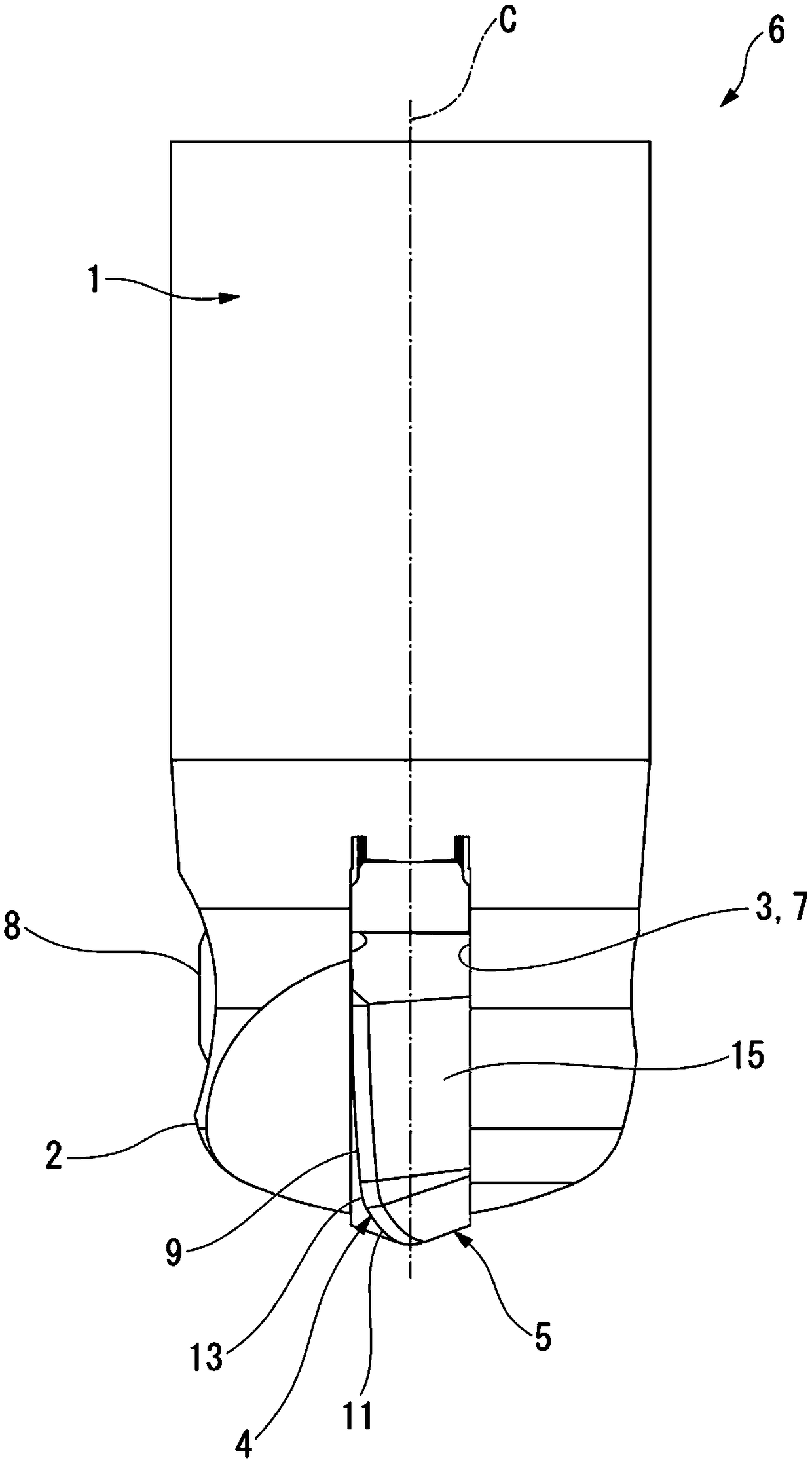

[0068] Next, a cutting insert 5 according to an embodiment of the present invention and an indexable insert type rotary cutting tool 6 including the cutting insert 5 will be described with reference to the drawings.

[0069] The cutting insert 5 of the present embodiment is a compound arc radius insert provided with a compound arc radius cutting edge, wherein the compound arc radius cutting edge consists of a so-called convex arc-shaped bottom cutting edge 11 called a lens, a so-called The outer peripheral cutting edge 9 of the convex arc shape of the drum and the convex arc radius cutting edge 13 of the cutting edge 13 connecting the bottom cutting edge 11 and the outer peripheral cutting edge 9 are constructed. Furthermore, the indexable insert type rotary cutting tool 6 having the cutting insert 5 is suitable for performing various cutting processes including end face cutting (surface machining) and side cutting (vertical wall surface machining) on a workpiece, and can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com