Refrigeration device for a power converter

A technology for power converters and cooling devices, used in indirect heat exchangers, cooling/ventilation/heating retrofits, electrical solid devices, etc., which can solve the complex installation of recirculation pumps, increase the possibility of failure, and reduce assembly reliability, etc. problems, to the effect of reducing the likelihood of failure and costly downtime, reducing the likelihood of leaks, and improving assembly reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The object of the present invention is a device for discharging heat, replacing the mentioned hydraulic circuit with one or more preferably tubular conduits which will extend from the point of generation of heat to the point of discharge.

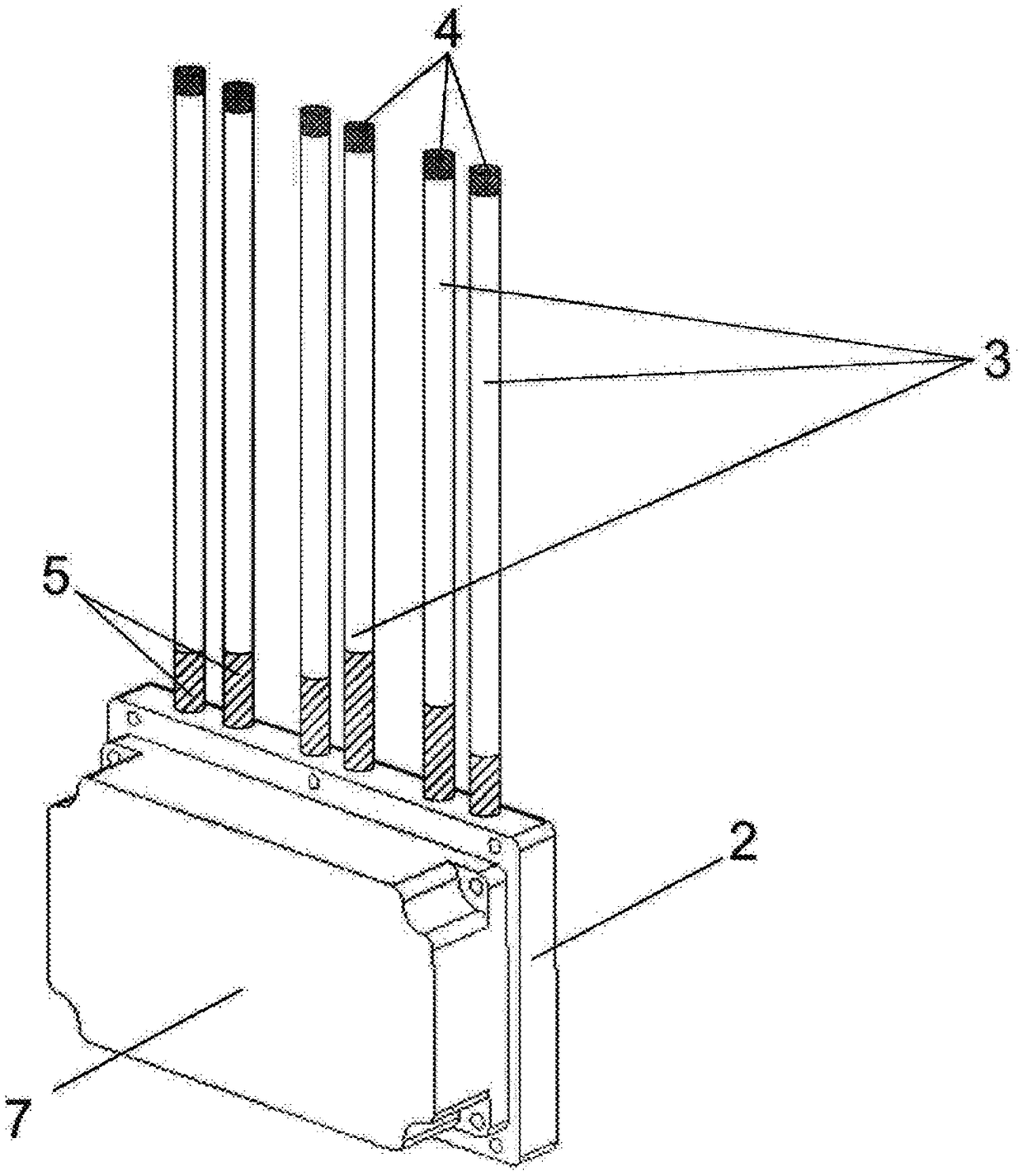

[0030] exist figure 1 In the shown embodiment of the invention, the power semiconductors (7) are coupled to a metal plate (2) into which a preferably tubular conduit (3) is inserted.

[0031] The conduit (3) can be fully inserted into the metal plate (2) or can be partially inserted, eg placed against one side of the metal plate (2).

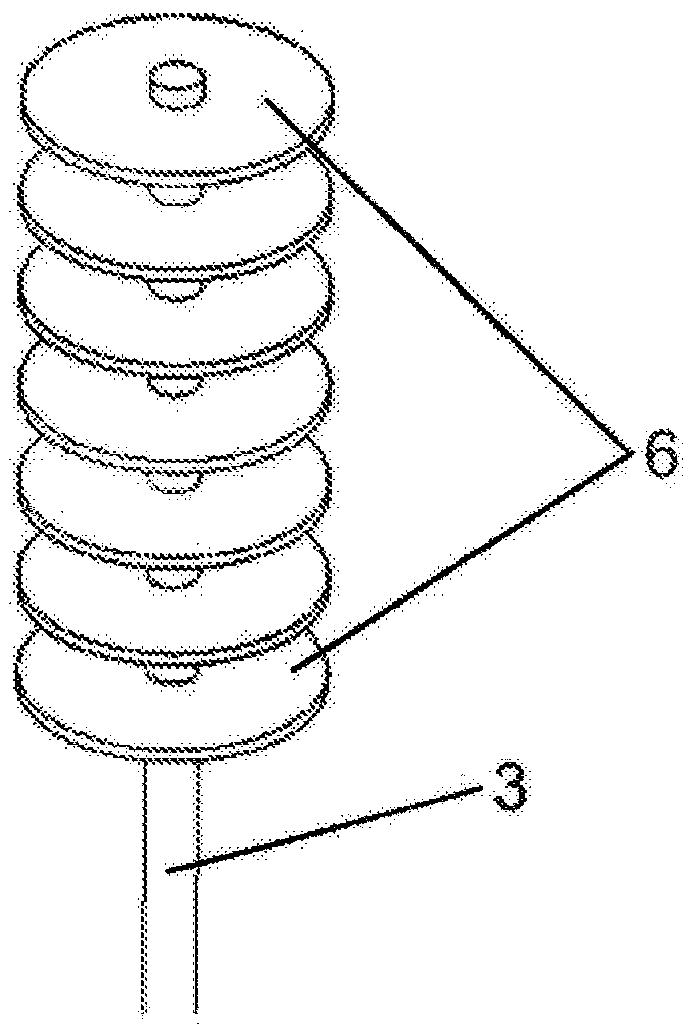

[0032] The fluid (5) performs a thermodynamic cycle based on phase change within the conduit (3). The lower part of the conduit (3), called the evaporator, receives the heat to be dissipated, and the fluid in liquid phase evaporates and turns into vapour. Due to the difference in density between the liquid and vapor states of all fluids, the vapor moves up to the higher and cooler part of the conduit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com