Aquaculture feeding equipment with charger and lifting mechanism

A feeder and feeding technology, which is used in fish farming, cranes, transportation and packaging, etc., can solve the problems of unpacking and cleaning, easy to slip away, and errors, etc., and achieves the effect of saving infrastructure costs and making choices flexible and convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solution of the present application will be further described in detail through the following embodiments in conjunction with the accompanying drawings. Apparently, the described embodiments are only part of the embodiments of the present application.

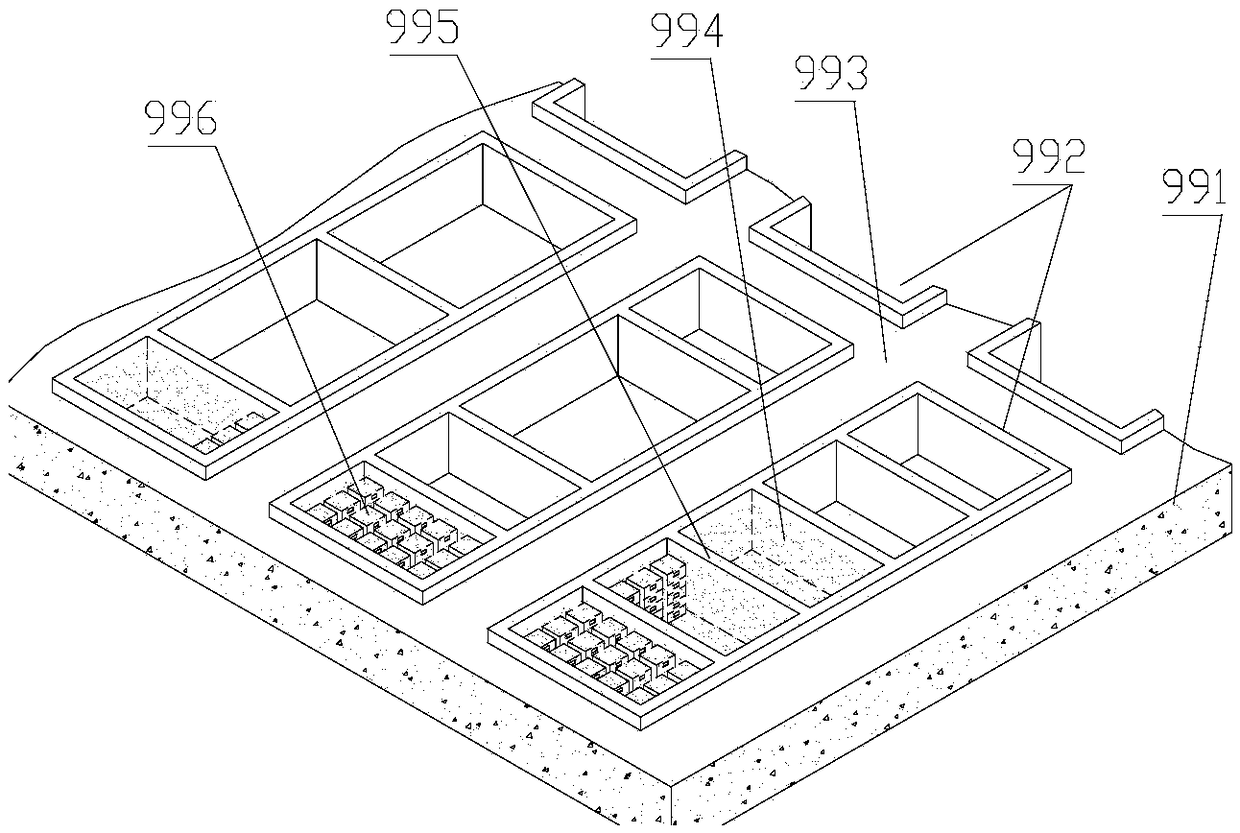

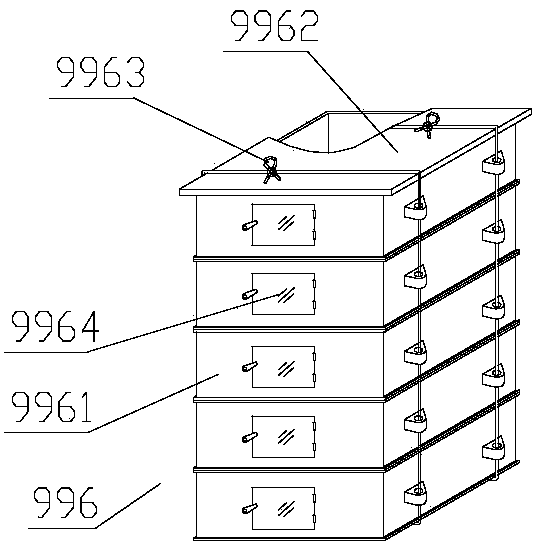

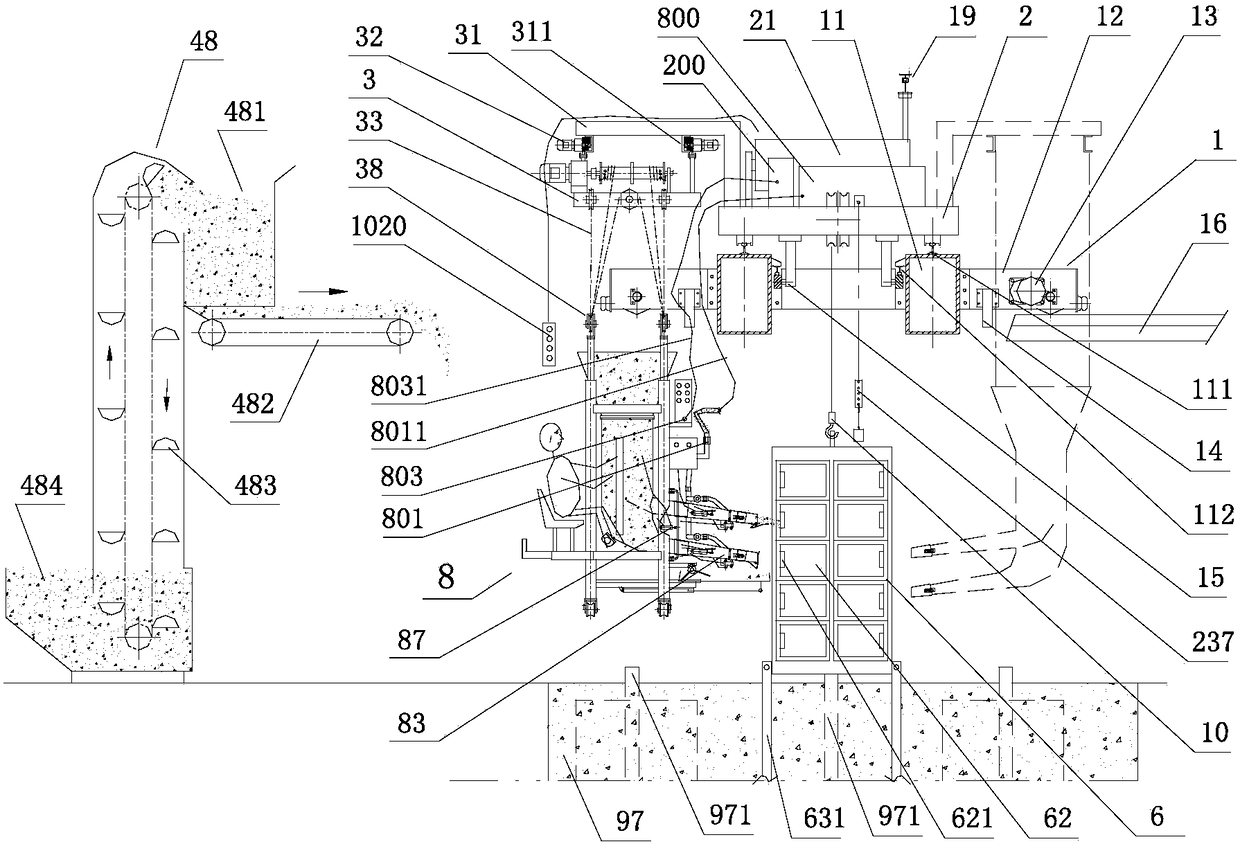

[0049] Such as image 3 , Figure 4 , Figure 5 As shown, it is the front view, side view, and top view of a kind of aquaculture feeding equipment with a feeder and a lifting mechanism described in the first embodiment of the application. The feeding equipment package, crane 1, feeder 8. Air compressor 800, feeding machine 48, a pair of limit guide posts 971 are provided in the culture pond 97, and the limit guide pillars stand vertically on the culture pond, and one end is fixed on the bottom surface of the culture pond, and the limit The guide post is provided with a limit groove rail in the vertical direction, and the top of the limit groove rail is provided with a bell mouth, water is housed in the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com