Grinding device for food processing machine

A technology for food processing machines and grinding devices, applied in applications, kitchen utensils, home utensils, etc., can solve the problems of inability to achieve filter-free slag-free, delicate taste, and motor shaft movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

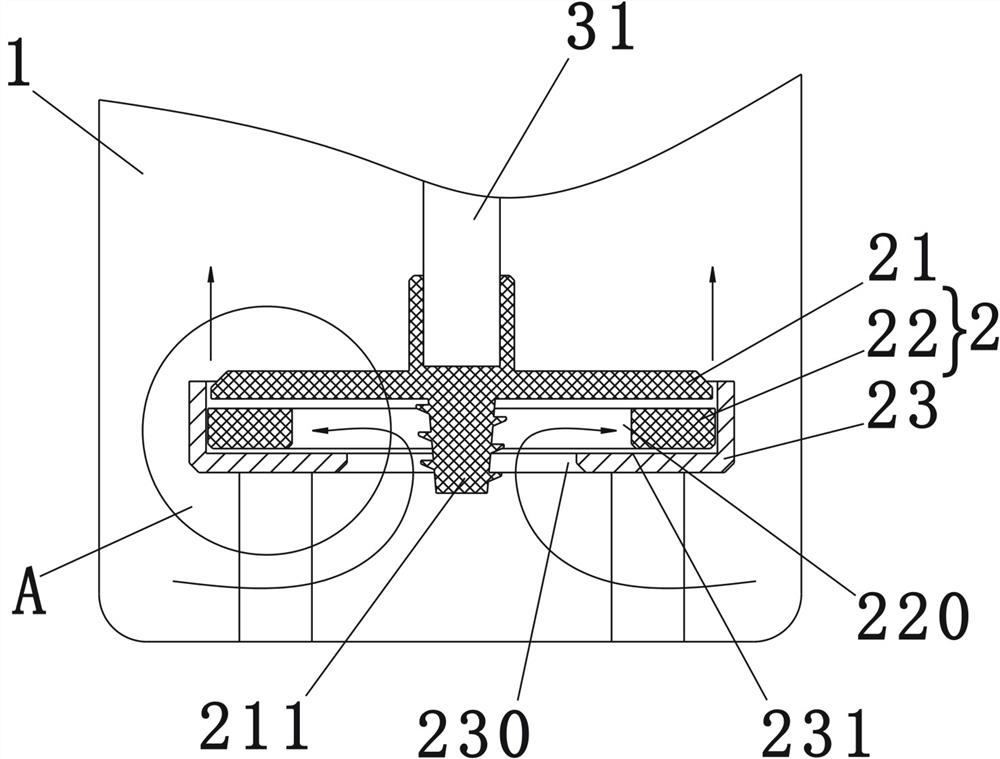

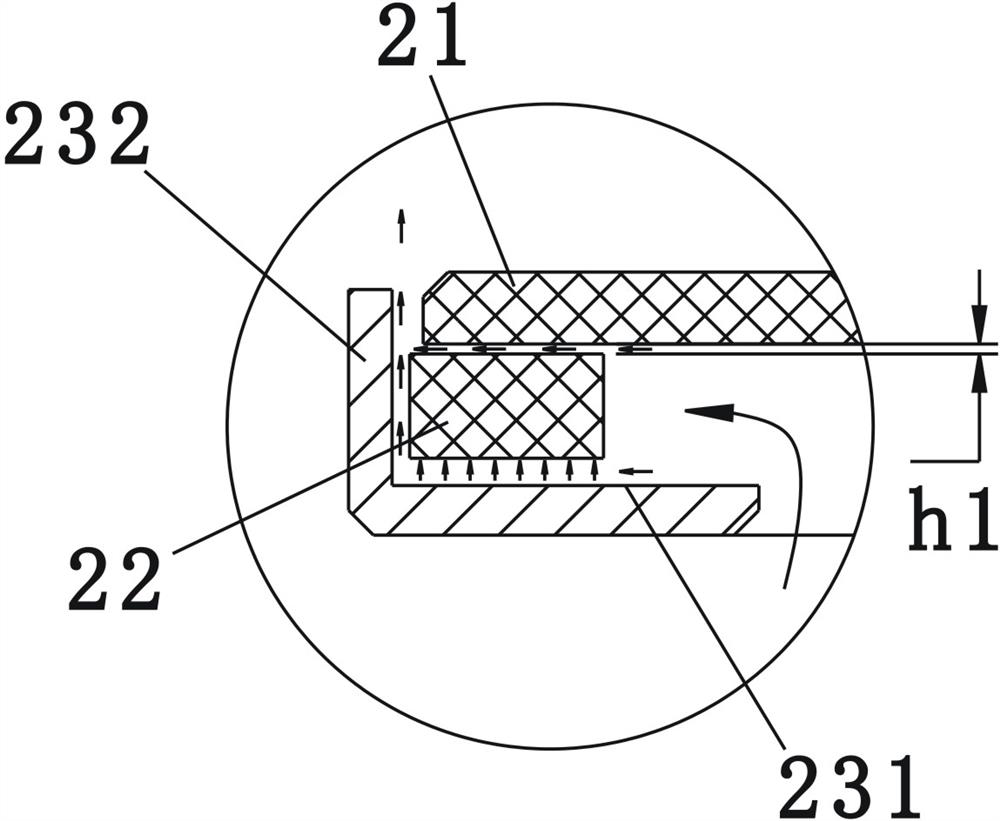

[0055] Such as figure 1 , figure 2 Shown is a schematic structural diagram of the first embodiment of the present invention. A food processing machine, comprising a cup body 1, a grinding device 2 is arranged in the cup body 1, and the grinding device 2 includes a rotating grinding disc 21 installed at the end of a rotating shaft 31 driven by a motor (not shown in the figure), Form a floating grinding disc 22 for plane grinding with the rotating grinding disc 21 and a support member 23 for supporting the floating grinding disc 22, the floating grinding disc 22 has a through hole 220 through the center, and the supporting member 23 has a supporting surface 231 for supporting the floating grinding disc 22 , and the edge of the supporting surface 231 is formed with a material passing opening 230 corresponding to the through hole 220, the rotating grinding disc 21 is located above the floating grinding disc 22, and when the rotating shaft 31 drives the rotating grinding disc 21 ...

Embodiment 2

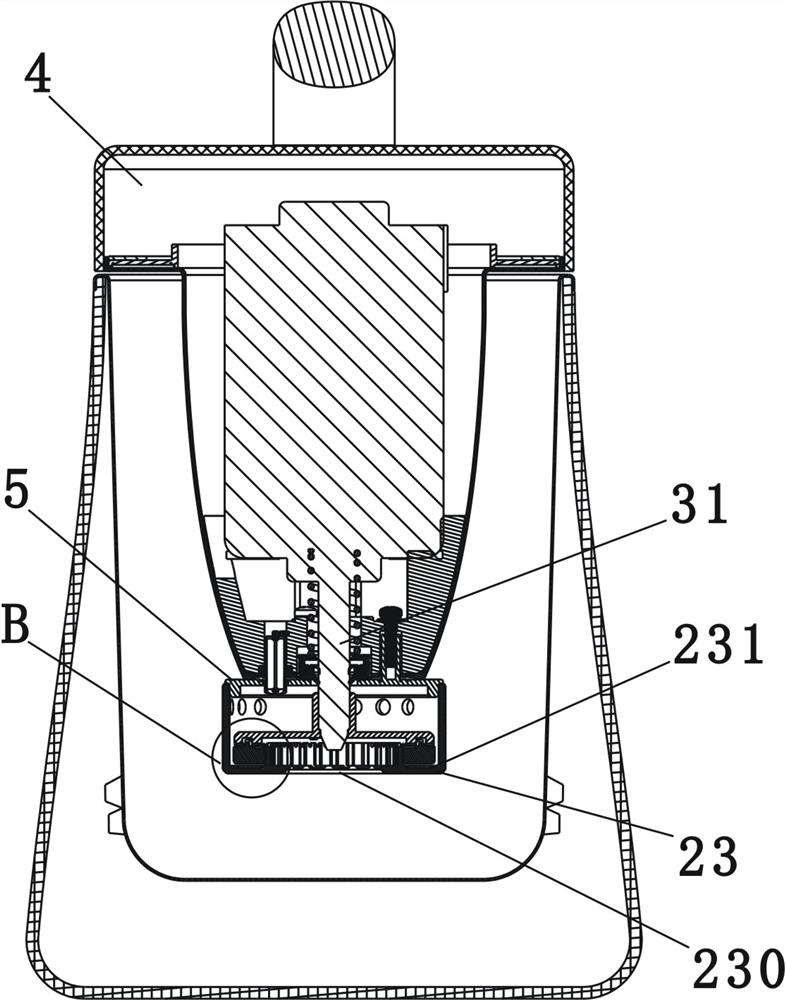

[0064] Such as Figure 3 to Figure 10 Shown is a schematic structural diagram of the second embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that in this embodiment, the bottom of the machine head 4 is provided with a connecting piece 5, and the supporting piece 23 is a crushing cover screwed on the connecting piece 5, and the crushing cover has a barrel shaped peripheral wall 233, the barrel-shaped peripheral wall 233 is provided with a through hole 235, the rotating grinding disc 21 and the floating grinding disc 22 are located in the installation cavity formed by the barrel-shaped peripheral wall 233, and the supporting surface 231 is provided with an upward annular Protrusion 234, the annular protrusion 234 is arranged around the feeding opening 230, and the annular protrusion 234 extends into the through hole to radially limit the floating grinding disc 22, wherein the annular protrusion 234 is surrounded by the barrel-shaped...

Embodiment 3

[0073] Such as Figure 11 , Figure 12 , Figure 13 , Figure 14 Shown is a schematic structural view of the third embodiment of the present invention. The difference between this embodiment and Embodiment 2 is that in this embodiment, the support member is a guide tube 6, and the guide tube 6 is fixed on the bottom of the machine head by means of a screw clamp, and the surrounding wall of the guide tube 6 A discharge hole 60 is arranged on the top, and the bottom of the guide tube 6 shrinks to form an opening, and the material and liquid flow enter from the open end, and the guide tube 6 is located above the opening and is provided with a step surface 61 supporting the floating grinding disc 22, And the step surface 61 is provided with a positioning hole 610, and the bottom of the floating grinding disc 22 is provided with a positioning post 2210, and the positioning post 2210 cooperates with the positioning hole 610 to realize that the floating grinding disc 22 does not r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com