Preparation method of anti-slip, wear-resistant and easy-to-clean ceramic tile

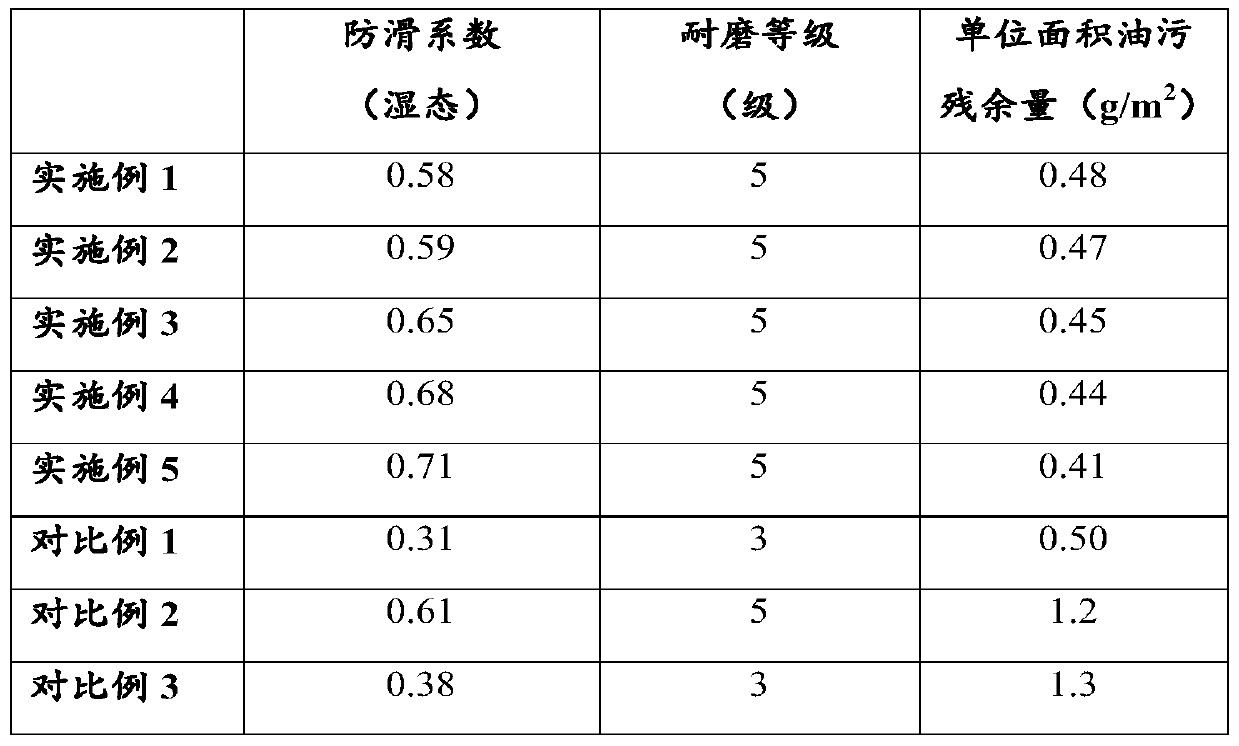

A non-slip and ceramic tile technology, applied in the field of architectural ceramics, can solve the problems of insufficient surface wear resistance, easy to scratch, low anti-slip coefficient, etc., and achieve the effect of not easy to wear, high anti-slip coefficient, and easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the anti-slip, wear-resistant and easy-to-clean ceramic tile provided by the present invention comprises the following steps:

[0026] (a) preparing a green body layer from a blank;

[0027] (b) applying top glaze on the body layer to form a top glaze layer;

[0028] (c) preparing a decorative layer by inkjet printing on the glaze layer;

[0029] (d) Printing anti-slip and wear-resistant glaze on the decorative layer to form an anti-slip and wear-resistant layer. The anti-slip and wear-resistant glaze is mainly prepared from anti-slip and wear-resistant particles, and the anti-slip and wear-resistant particles are mainly composed of the following components in parts by mass: Composition: SiO 2 60-70 parts, Al 2 o 3 20-30 parts, Fe 2 o 3 0.01~0.1 parts, TiO 2 0.1~2 parts, Na 2 O 1~5 parts, K 2 1-10 parts of O, 0.1-1 part of MgO, 0.1-5 parts of CaO and 0.1-2 parts of loss on ignition;

[0030] (e) Applying an easy-clean protective g...

Embodiment 1

[0084] This embodiment provides a preparation method of anti-slip, wear-resistant and easy-to-clean ceramic tiles, which is carried out according to the following steps:

[0085] (a) The billet is firstly wet ball milled to make a moisture content of 6.3%, particle gradation of 1% above 20 mesh, 45% of -20~40 mesh, 80% of -20~60 mesh, and below 100 mesh 3%, the balance is -60 to 100 mesh slurry; then the slurry is pressed through a concave-convex mold to form a green body layer with a concave-convex effect; wherein, the blank is composed of the following components in parts by mass: 20 parts of quartz sand, potassium 15 parts of sodium sand, 18 parts of washed clay, 44 parts of white clay, 31 parts of potassium sand, 1 part of bentonite and 2.5 parts of black talc;

[0086] (s) Put the green body layer into a drying kiln for one drying, the drying temperature is 130°C, and the drying cycle is 60 minutes;

[0087] (b) Apply glaze on the body layer after primary drying to form ...

Embodiment 2

[0095] This embodiment provides a preparation method of anti-slip, wear-resistant and easy-to-clean ceramic tiles. The difference between this embodiment and Example 1 is that the anti-slip and wear-resistant particles are composed of the following components in parts by mass: SiO 2 70 parts, Al 2 o 3 20 parts, Fe 2 o 3 0.1 parts, TiO 2 2 parts, Na 2 O 1 part, K 2 5 parts of O, 1 part of MgO, 0.8 parts of CaO and 0.1 part of loss on ignition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| wear coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com