Method for continuously producing 4-phenylmorpholine

A technology of phenylmorpholine and manganese benzoate is applied in the field of continuous production of 4-phenylmorpholine, and achieves the effects of simple raw materials, controllable reaction and good industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

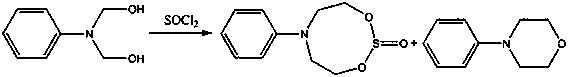

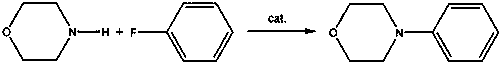

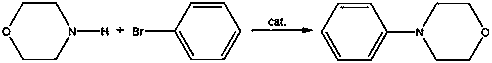

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 300.0g of manganese benzoate, 30.0g of N,N-dihydroxyethylaniline, 30.0g of phosphotungstic acid into the reaction kettle, protect it under nitrogen, raise the temperature to 160°C, and turn on the mechanical stirring to obtain a reaction medium with good fluidity. Raise the temperature to 300°C, add 70.0g of N,N-dihydroxyethylaniline dropwise, and collect the distilled fraction. After the reaction is over, 89.0g of crude product is collected, with a content of 92.0%. After recrystallization with water, 81.7g of 4 -Phenylmorpholine, content 99.0%, yield 90.8%. Product Characterization: 1 HNMR (400 MHz, CDCl 3 ):δ=6.88–6.93,7.25–7.30(m,5H),

[0039] 3.83-3.88(t,4H),3.14-3.18ppm(t,4H).

Embodiment 2

[0041] Add 300.0g of manganese benzoate, 60.0g of N,N-dihydroxyethylaniline, and 15.0g of phosphotungstic acid into the reactor, protect it under nitrogen, raise the temperature to 180°C, and turn on mechanical stirring to obtain a reaction medium with good fluidity. Raise the temperature to 310°C, add 40.0g of N,N-dihydroxyethylaniline dropwise, and collect the distilled fraction. After the reaction is over, 88.0g of crude product is collected, with a content of 95.6%. After recrystallization with water, 81.9g of 4 -Phenylmorpholine, content 99.2%, yield 91.0%.

Embodiment 3

[0043] Add 300.0g of manganese benzoate, 90.0g of N,N-dihydroxyethylaniline, and 18.0g of phosphotungstic acid into the reactor, protect it under nitrogen, raise the temperature to 200°C, and turn on mechanical stirring to obtain a reaction medium with good fluidity. Raise the temperature to 320°C, add 110.0g of N,N-dihydroxyethylaniline dropwise, and collect the distilled fraction. After the reaction is over, 184.0g of crude product is collected, with a content of 90.5%. After recrystallization with water, 164.4g of 4 -Phenylmorpholine, content 99.1%, yield 91.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com