Novel gradient copolymer and preparation method thereof

A gradient copolymer, a new type of technology, applied in the field of polymers, can solve the problems of limited design and research reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] One aspect of the present invention provides a method for preparing the above-mentioned novel gradient copolymer with a wide glass transition temperature, wherein the method comprises the following steps:

[0048] Step 1, use monomer M' and monomer N' to polymerize to obtain a gradient copolymer, expressed as M x-grad -N y .

[0049] Wherein, the structural unit M is polymerized from the monomer M', and the structural unit N is polymerized from the monomer N', and x and y represent the degree of polymerization of the structural unit M and the structural unit N, respectively.

[0050] According to a preferred embodiment of the present invention, in step 1, the monomer M' is selected from non-hydrolyzable ethylenic monomers;

[0051] Wherein, preferably, the monomer M' is selected from monomers whose glass transition temperature differs greatly from the glass transition temperature of the monomer N', such as styrene;

[0052] In a further preferred embodiment, the mono...

Embodiment approach

[0059] According to a preferred embodiment of the present invention, the organoantimony-mediated radical polymerization (SBRP) is carried out as follows: using azobisisobutyronitrile as an initiator at 40-80°C.

[0060] In a further preferred embodiment, the organoantimony-mediated free radical polymerization (SBRP) is carried out as follows: using azobisisobutyronitrile as an initiator at 50-80°C.

[0061] In a further preferred embodiment, the organoantimony-mediated free radical polymerization (SBRP) is carried out as follows: using azobisisobutyronitrile as an initiator at 60°C.

[0062] Wherein, the above-mentioned free radical polymerization regulated by organoantimony (SBRP) is free radical polymerization regulated by organoantimony in bulk or in traditional organic solvents.

[0063] According to a preferred embodiment of the present invention, the molar ratio of the initiator to the organic antimony compound is 1:(1-5).

[0064] In a further preferred embodiment, the...

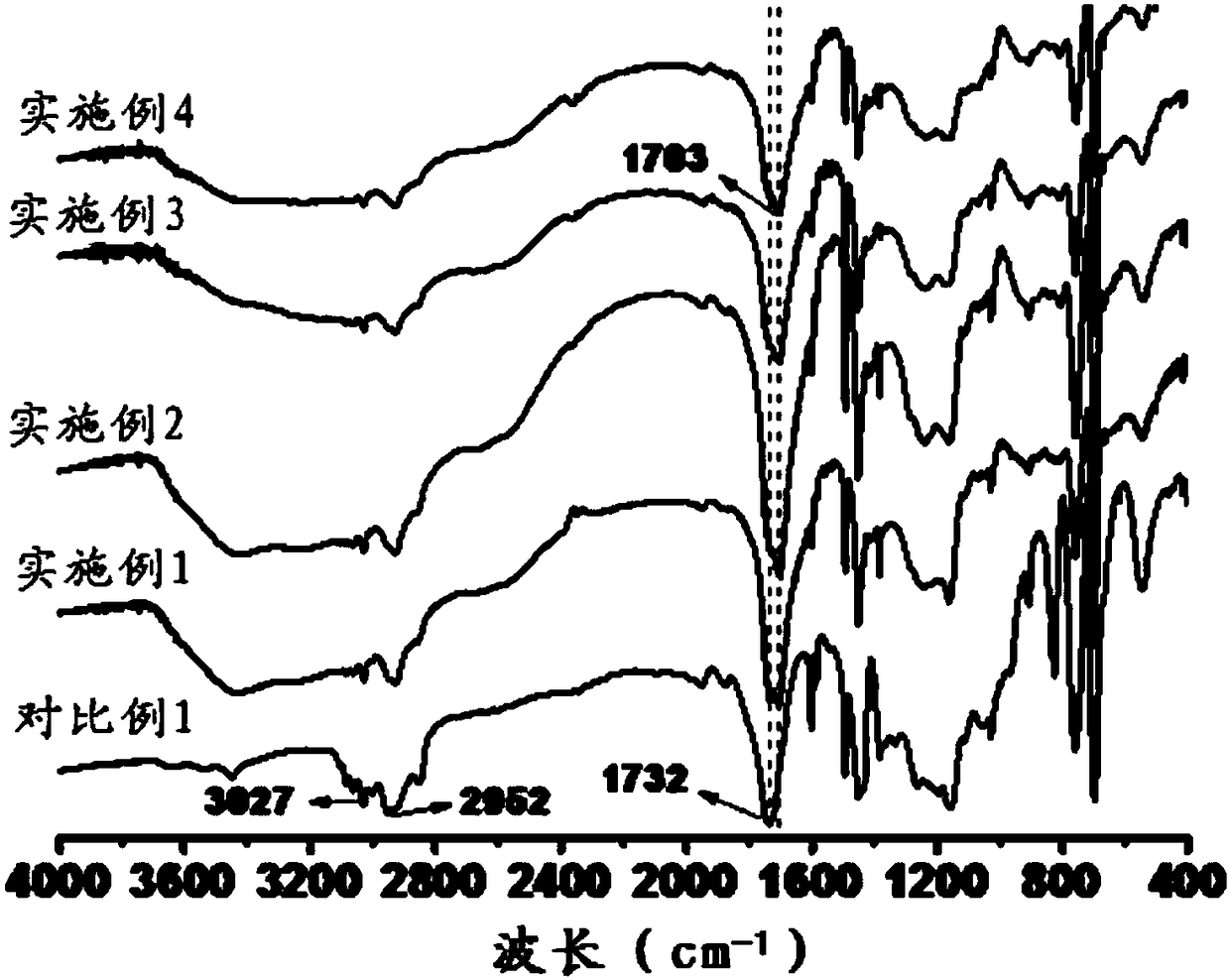

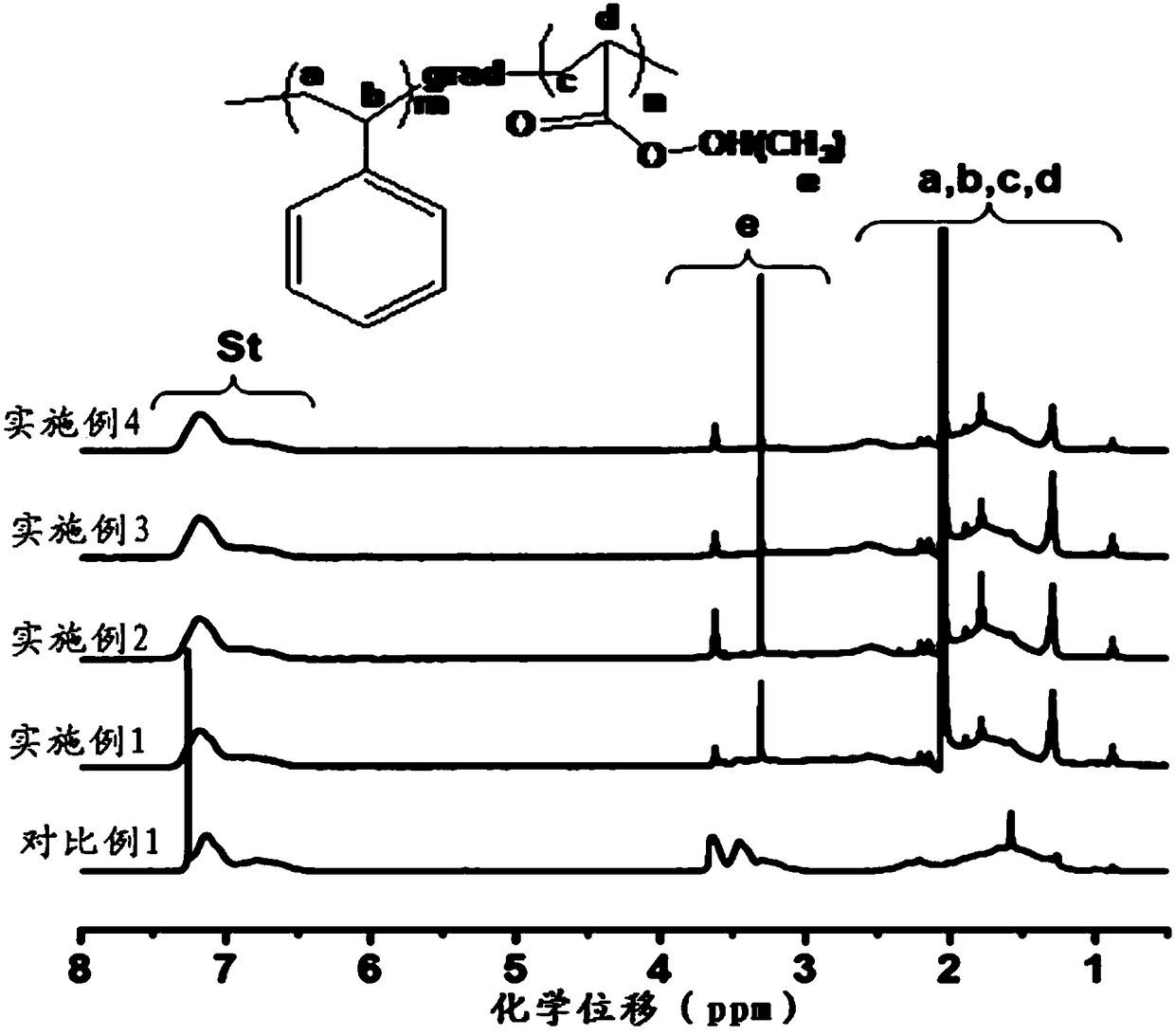

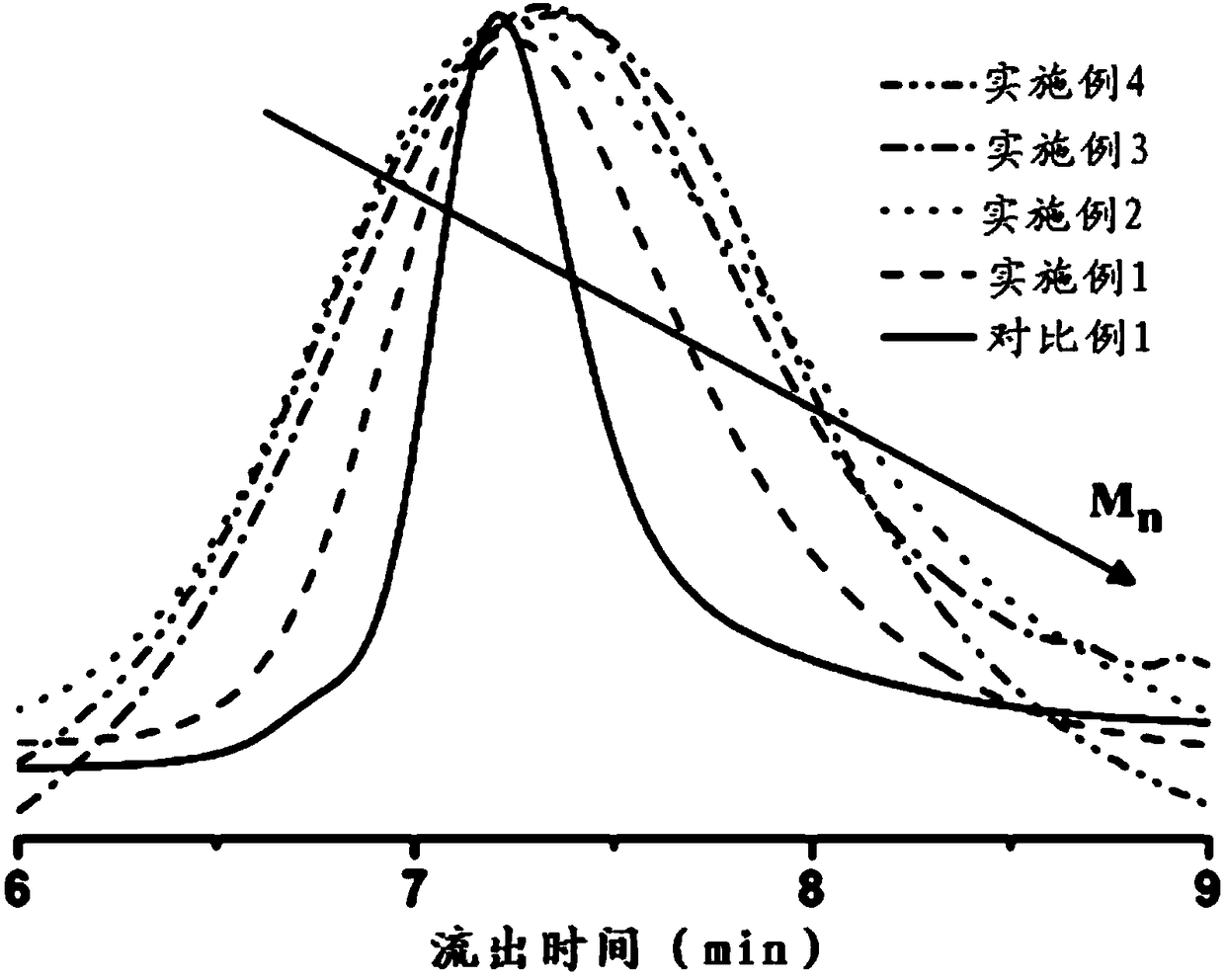

Embodiment 1

[0140] St (8.32g, 80mmol), AIBN (0.0821g, 0.5mmol) and a magnetic stir bar were added to a 50mL Schenk reaction flask, and MA (10.34, 121mmol) was added to another 50mL Schenk flask, both of which were subjected to freezing-pumping Vacuum-fill with argon, cycle three times, remove the air. Add ethyl 2-dimethylantimony-2-methylpropionate (EMSMP) (0.267g, 1mmol) into the first reaction bottle in the glove box, and place it in a pre-set 60°C oil bath for reaction, Then through a micro-syringe pump, at a constant flow rate (0.006mL min -1 ) Add MA monomer dropwise to the bottle. The polymerization reaction stopped 10 minutes after the MA was added dropwise, all the samples were taken out, dissolved in chloroform, and the polymer was precipitated by methanol, and dried in a vacuum oven at 40°C to constant weight to obtain the gradient copolymer St 40 -grad-MA 60 .

[0141] Will St 40 -grad-MA 60 (1g), tetrahydrofuran 20mL, 40% potassium hydroxide solution (1mL), and triethyla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com