A processor for calibrating an automotive look-around system

A technology for processors and automobiles, applied in image data processing, instruments, calculations, etc., can solve the problems of increasing the cost ratio of the surround view system, the difficulty of calibrating the left and right cameras, and the high requirements of the calibration environment, so as to avoid the possibility of convergence to non-planar High reliability, simple calibration scheme and high calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A processor for calibrating a car surround view system, the car surround view system includes a plurality of fisheye cameras, and the processor is used to execute the following computer program steps to obtain the rotation matrix Rt of each camera:

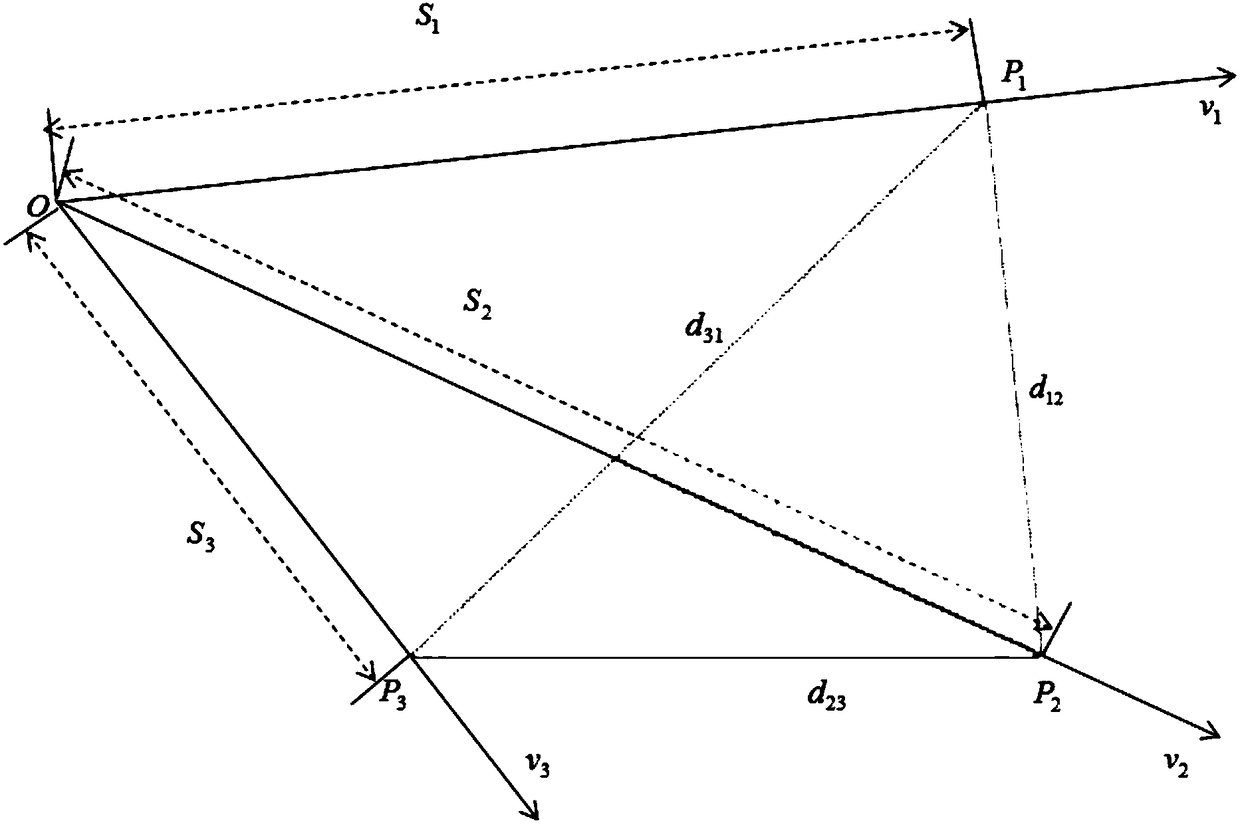

[0034] When the car is stationary, calculate the observation vectors v1, v2, and v3 from the camera to the three vertices of the known markers in the camera coordinate system based on the pixel coordinates of the three vertices on the captured image, and the composition of the connecting lines of the three vertices of the markers, etc. Triangular sides and fit to the horizontal ground, solve the observation distances s1, s2, s3 from the camera to the three vertices in the camera coordinate system, so that the distance between the three vertices satisfies d 12 = d 23 = d 31 =d, where d is the side length of an equilateral triangle, then obtain the coordinates of the three vertices under the camera coordinate system, thereby...

Embodiment 2

[0046] A calibration device for a car surround view system, comprising the processor described in Embodiment 1 and a marker arranged on a horizontal ground, where the marker is an equilateral triangular patch or an equilateral triangular frame that fits the horizontal ground.

[0047] Using an equilateral triangle as the basic graphic element is the core idea of the present invention, which breaks the customary idea of using lines or squares for calibration in most current calibration schemes. The equilateral triangle has some special advantages: First, the user can use three equal-length line segments to make an absolutely accurate equilateral triangle, and then cut it into a board, or paint a certain color on the corresponding area on the ground. The shape does not have this condition (users do not need to purchase additional accessories to calibrate their own surround view system, but can do it themselves with a ruler and a rope). Secondly, there is no strict order requ...

Embodiment 3

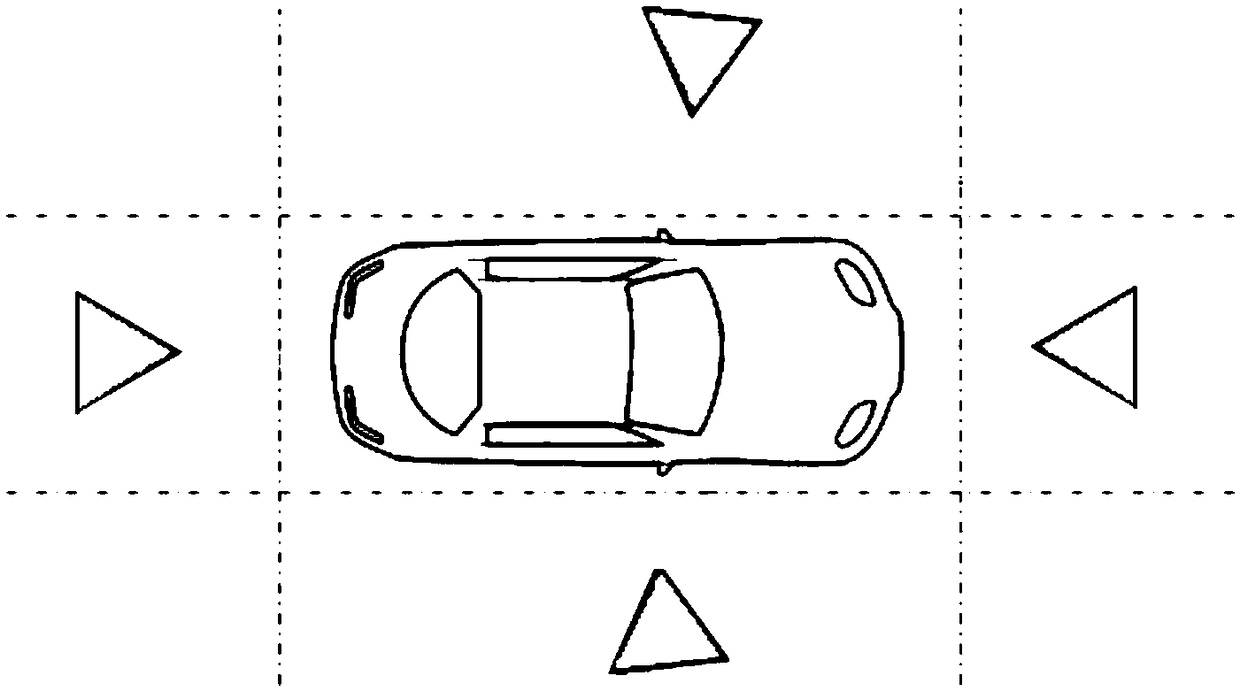

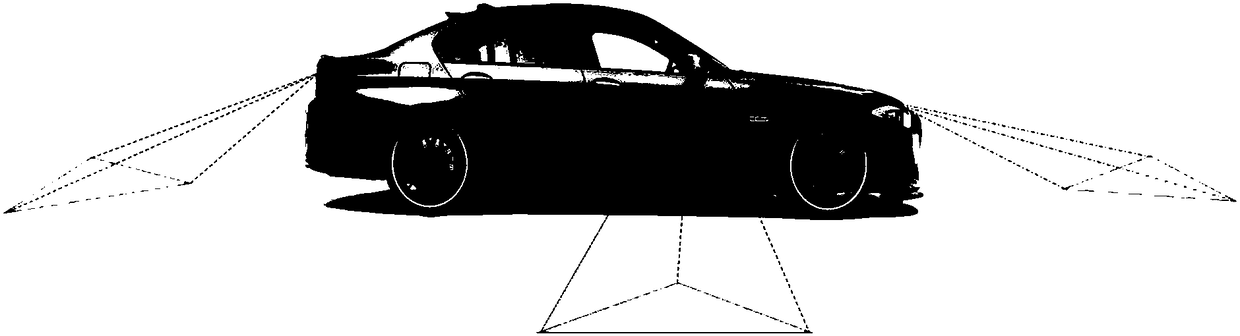

[0051] A car surround view system with the calibration device described in Embodiment 2, comprising a calibration device and a plurality of fisheye cameras. The fisheye camera can be four ultra-wide-angle fisheye cameras installed on the front, rear, left, and right sides of the vehicle body. When working, the four cameras simultaneously collect images around the vehicle. After the image processing unit distorts and restores→angle conversion→image stitching→image enhancement, the final form A 360-degree panoramic overhead view with no gaps around the vehicle. While displaying the panorama, it can also display the single view of any side, and coordinate with the ruler line to accurately locate the position and distance of obstacles. The calibration work is carried out before the vehicle is officially put on the road, such as figure 1 As shown, it shows a top view of a certain arrangement of the marker triangle. The triangle is also arranged at the front, rear, left, and right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com