Patents

Literature

80results about How to "Easy to operate independently" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

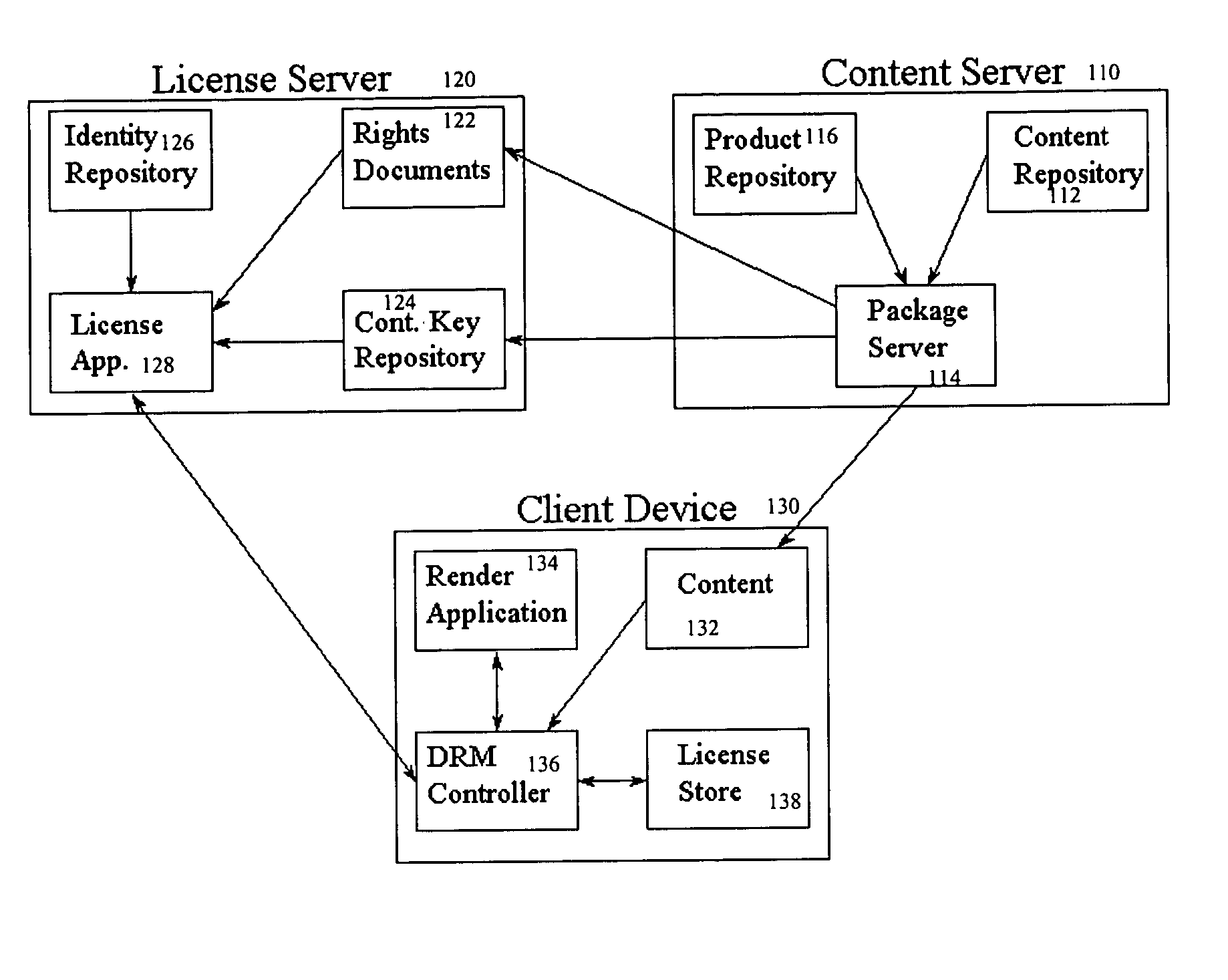

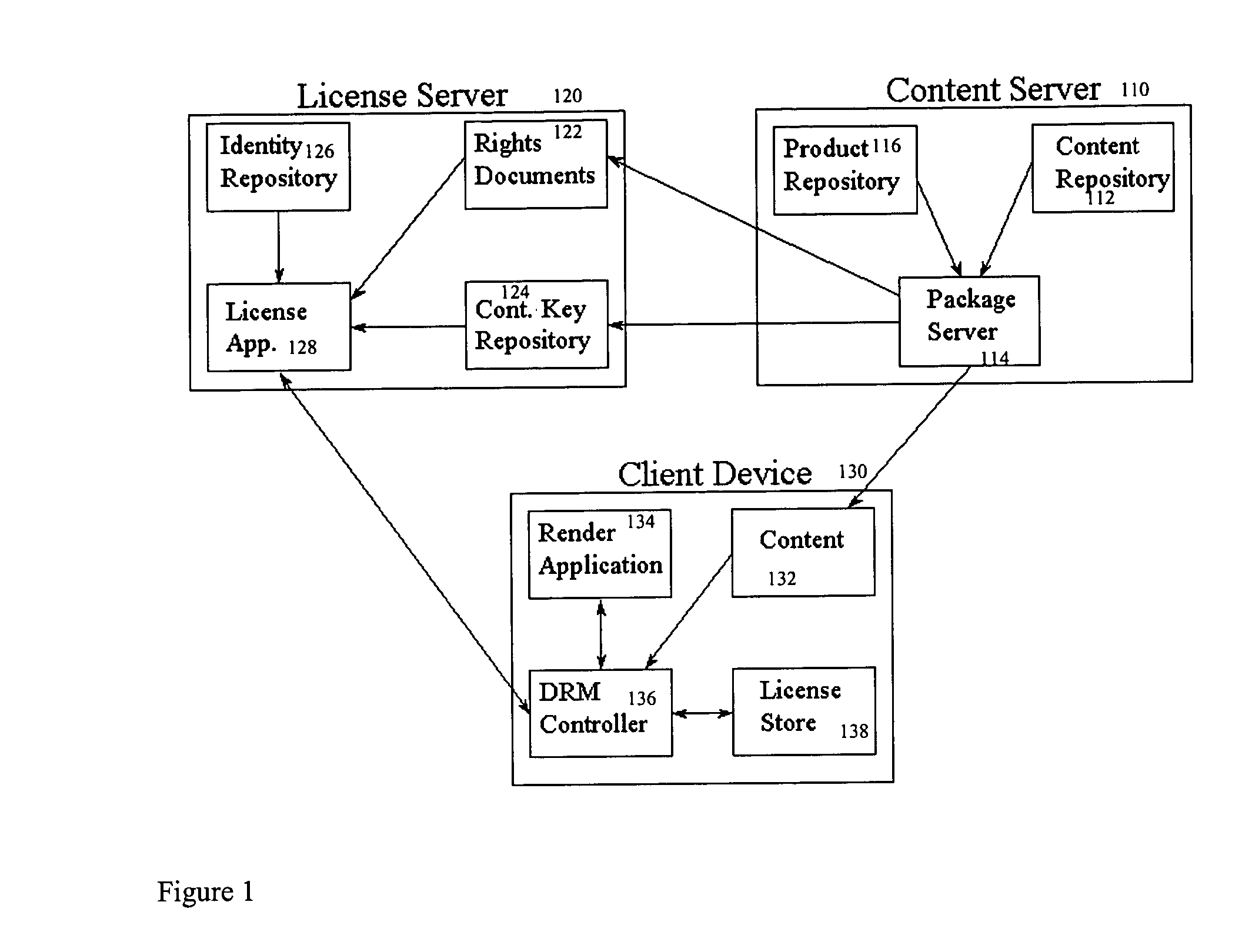

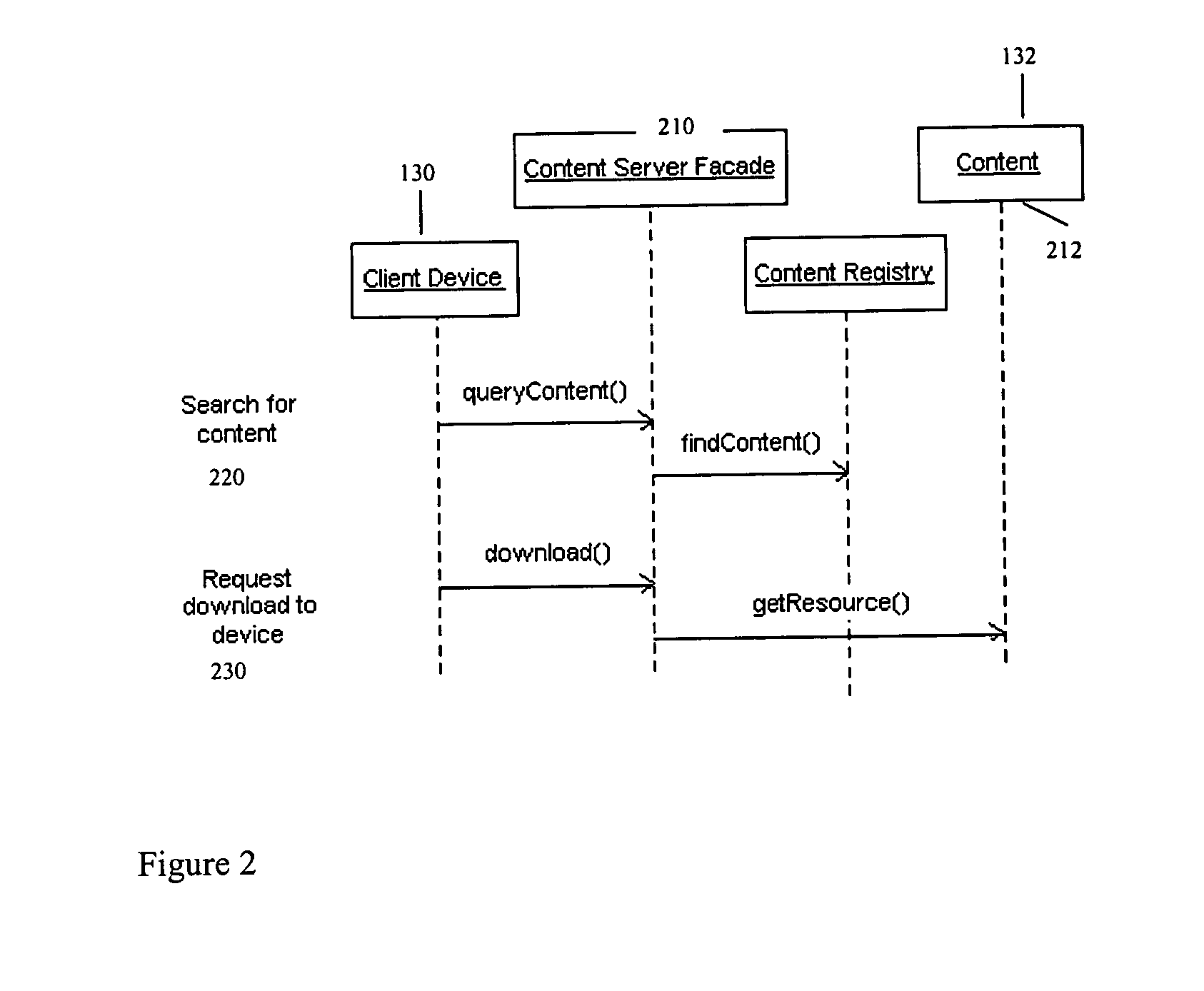

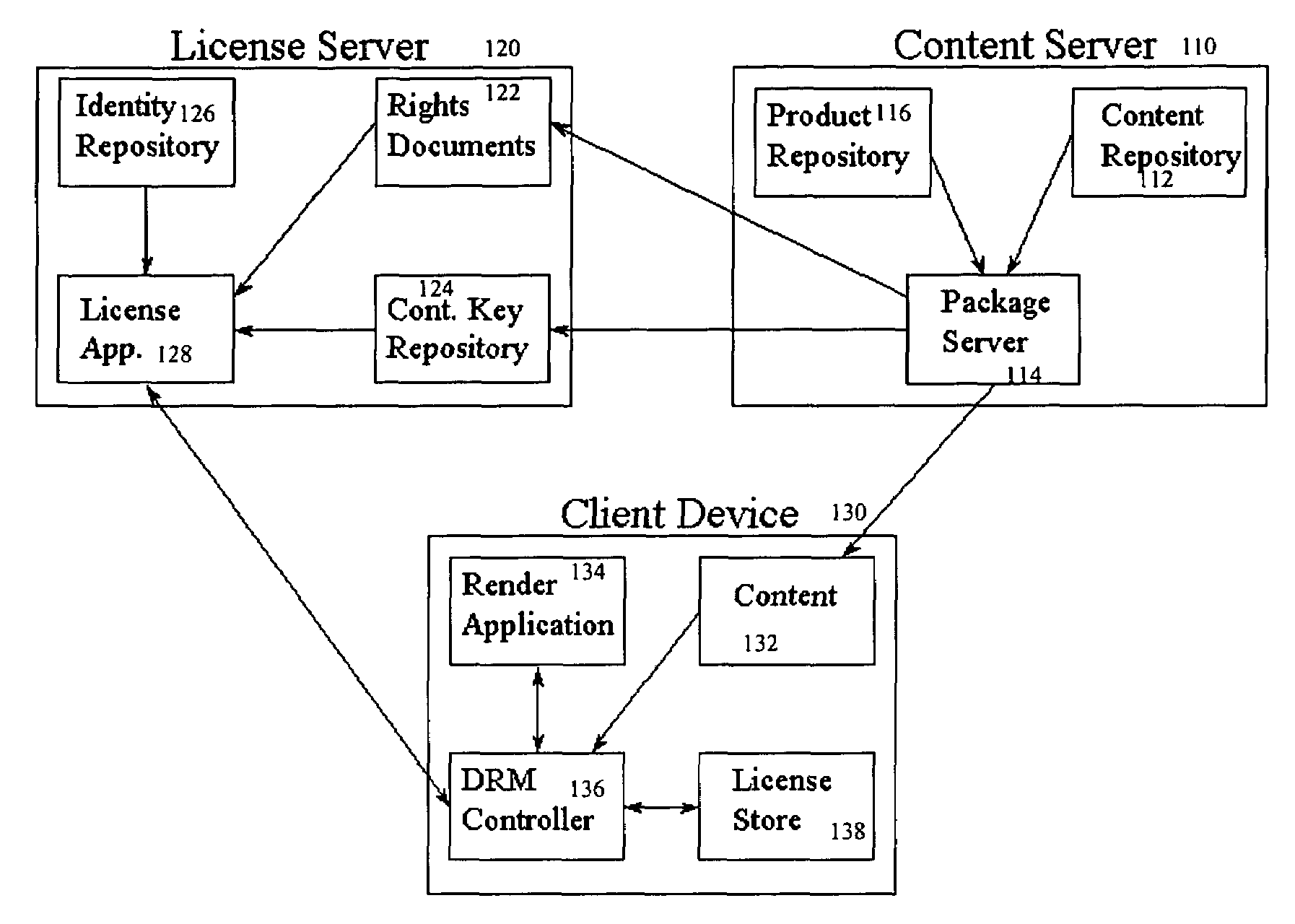

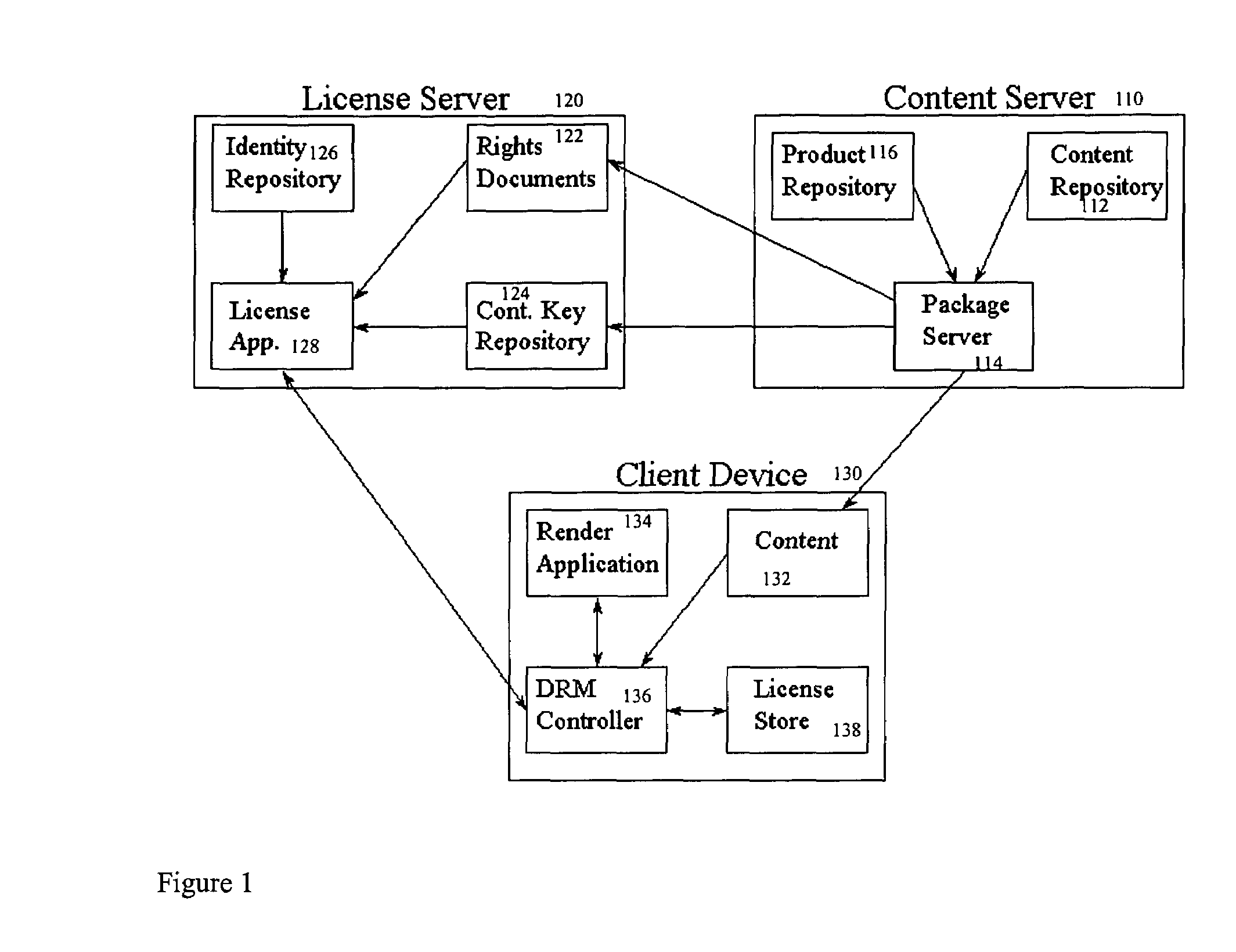

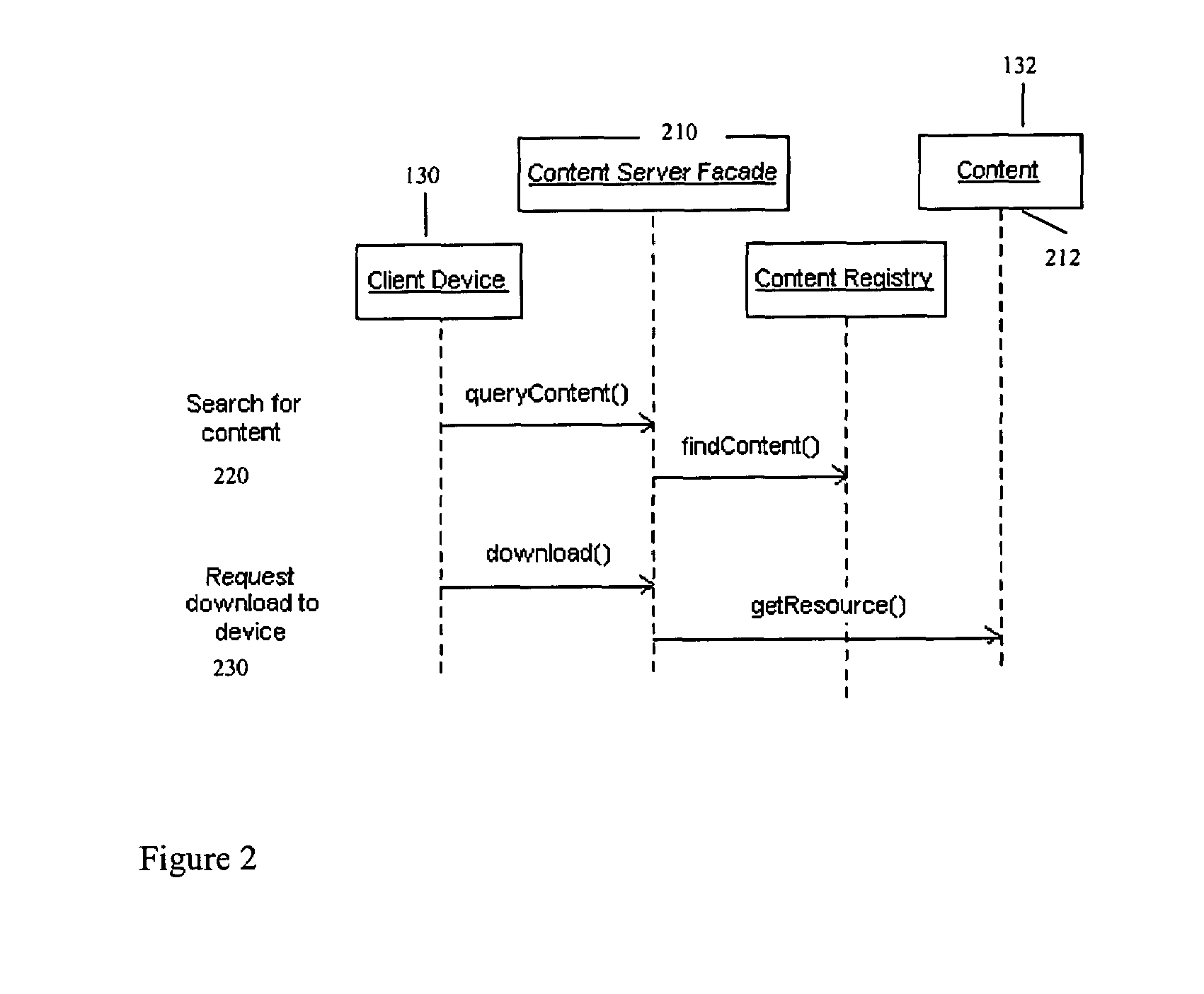

System and method for securing digital content

ActiveUS20050044016A1Simplify the purchasing processIntuitive experienceComplete banking machinesFinanceDigital contentDigital rights management system

Owner:NETCRACKER TECH SOLUTIONS

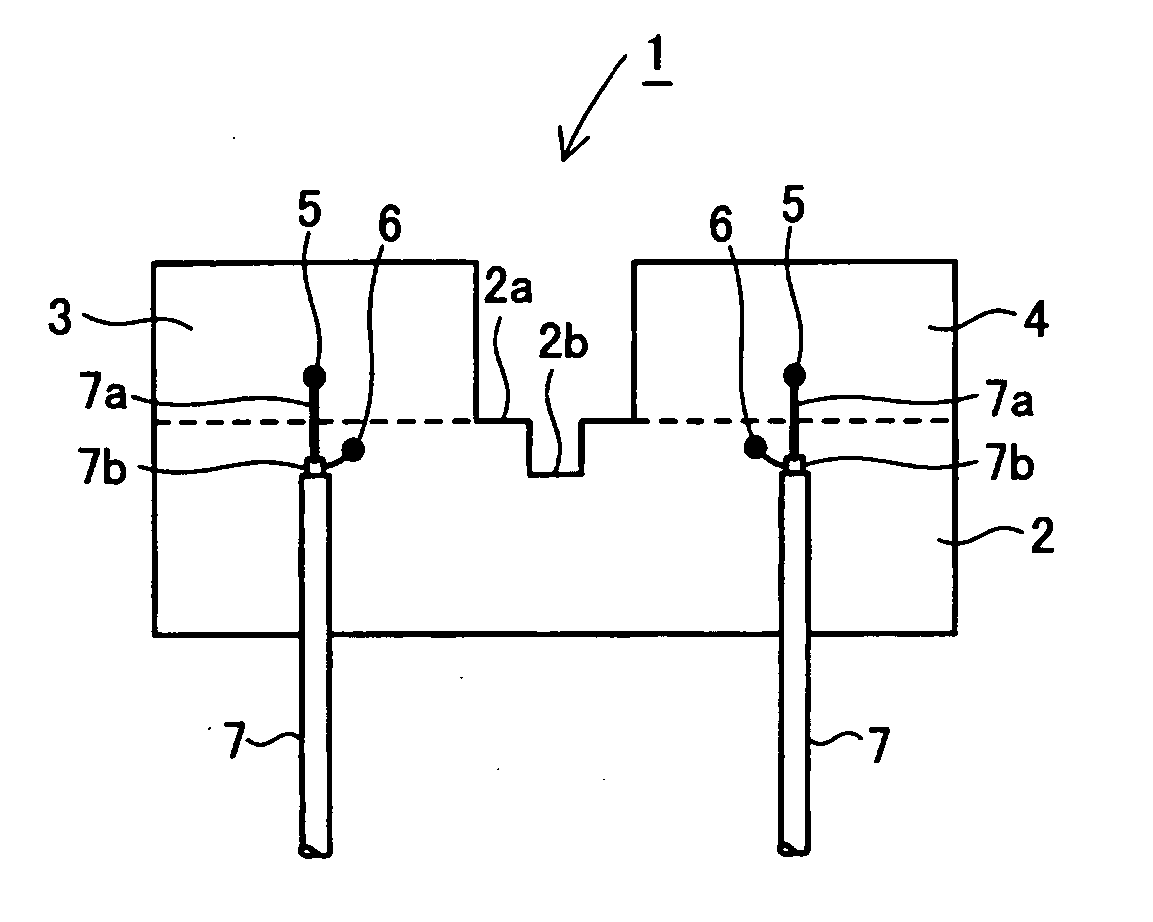

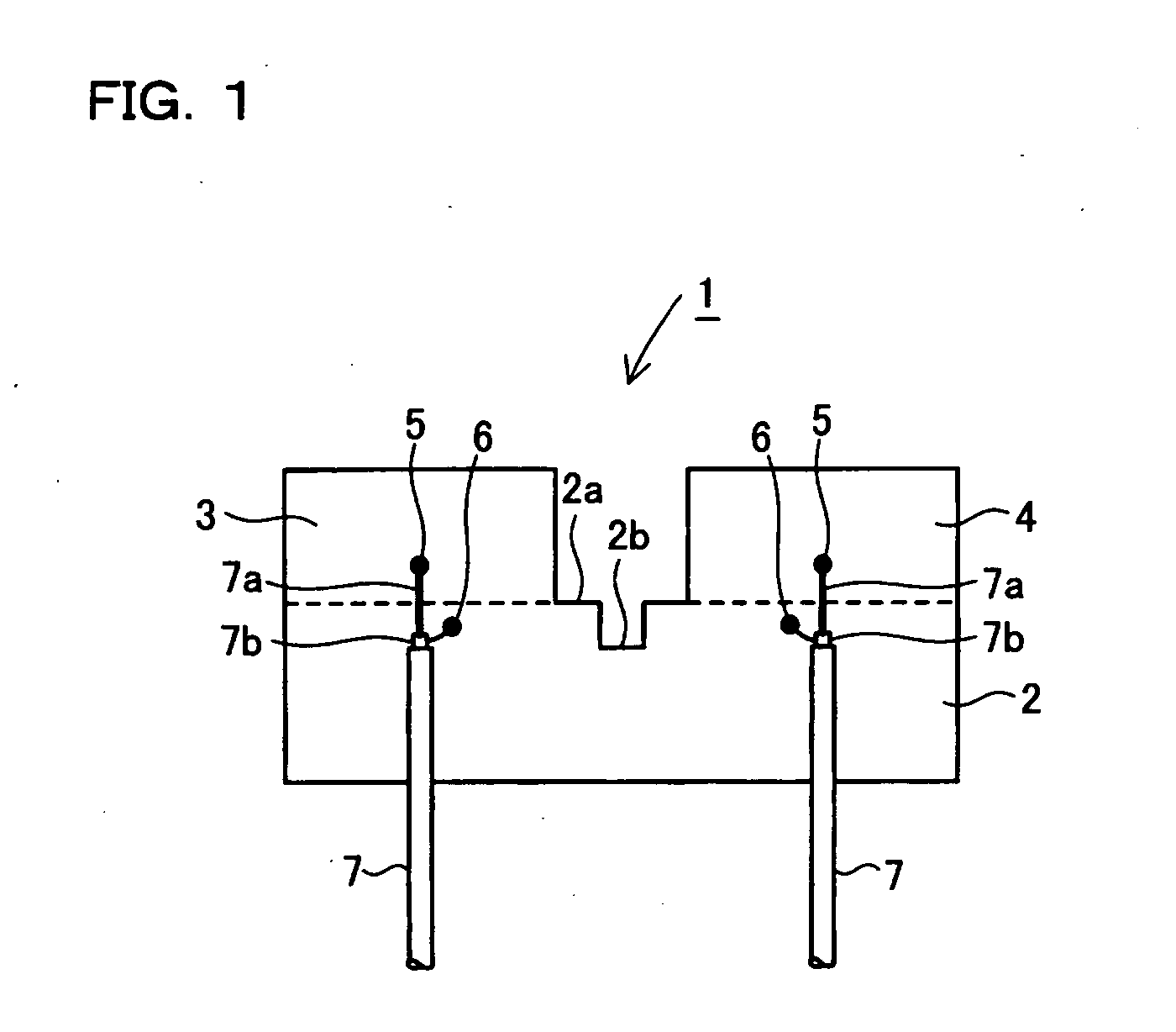

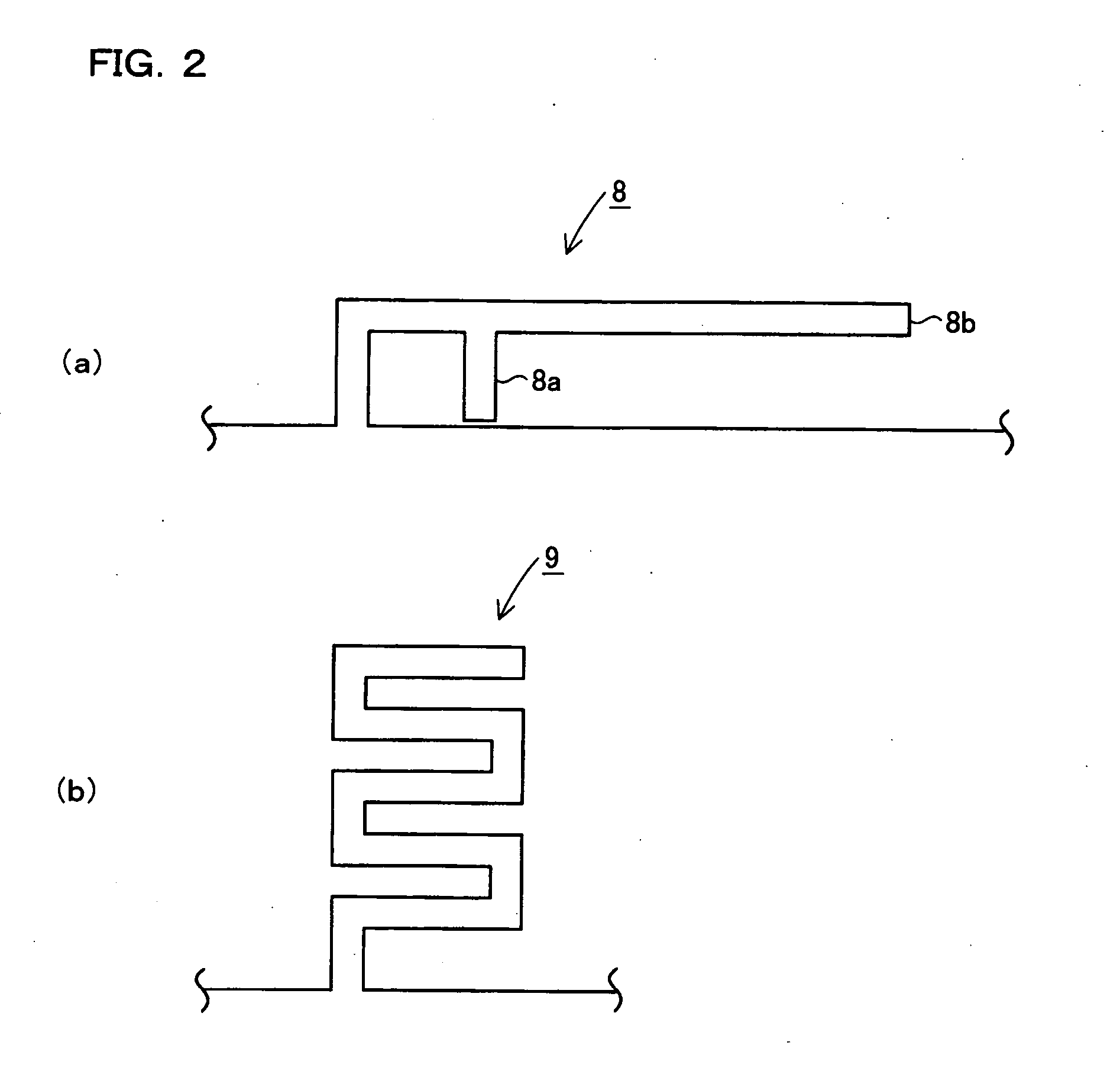

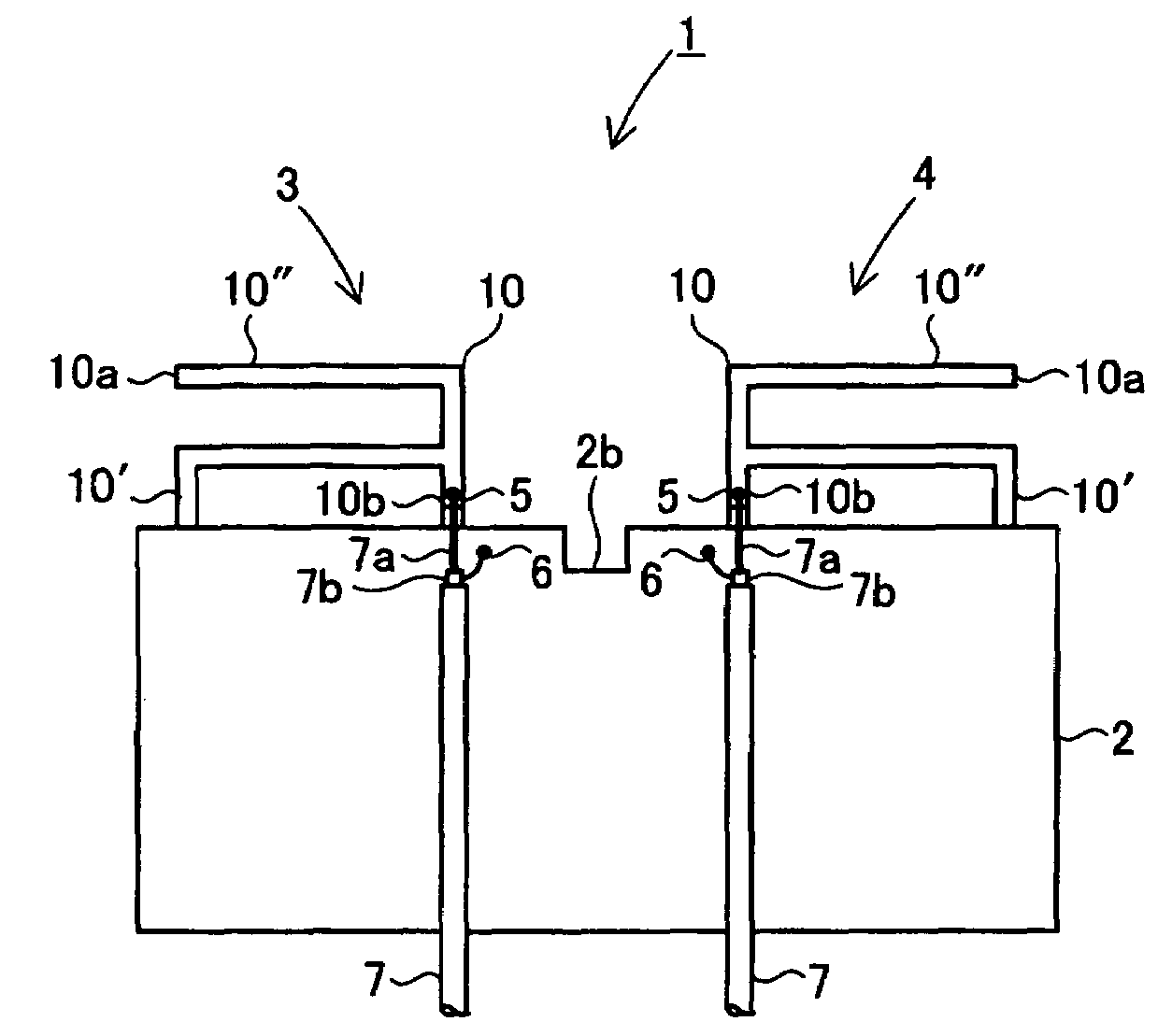

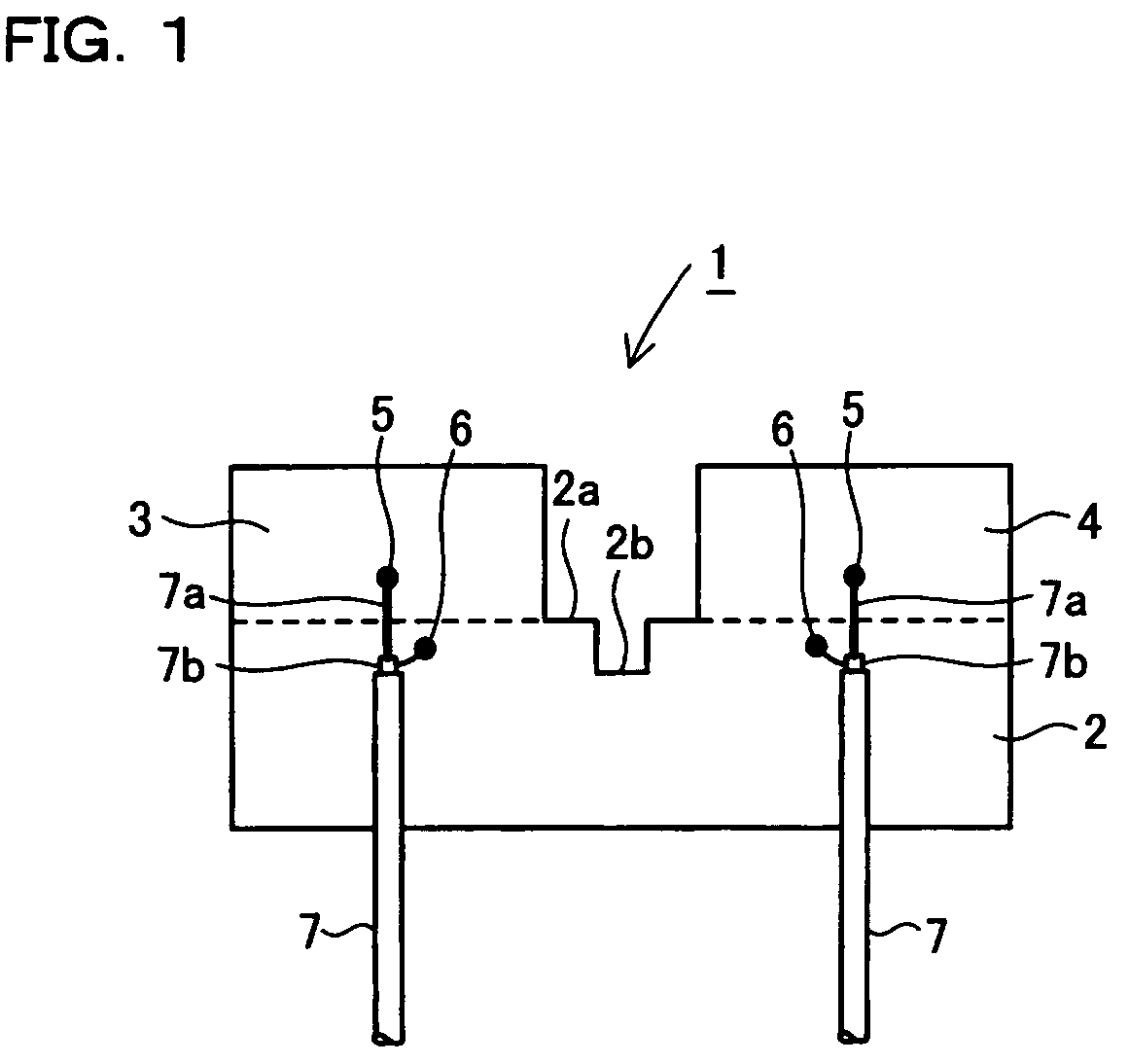

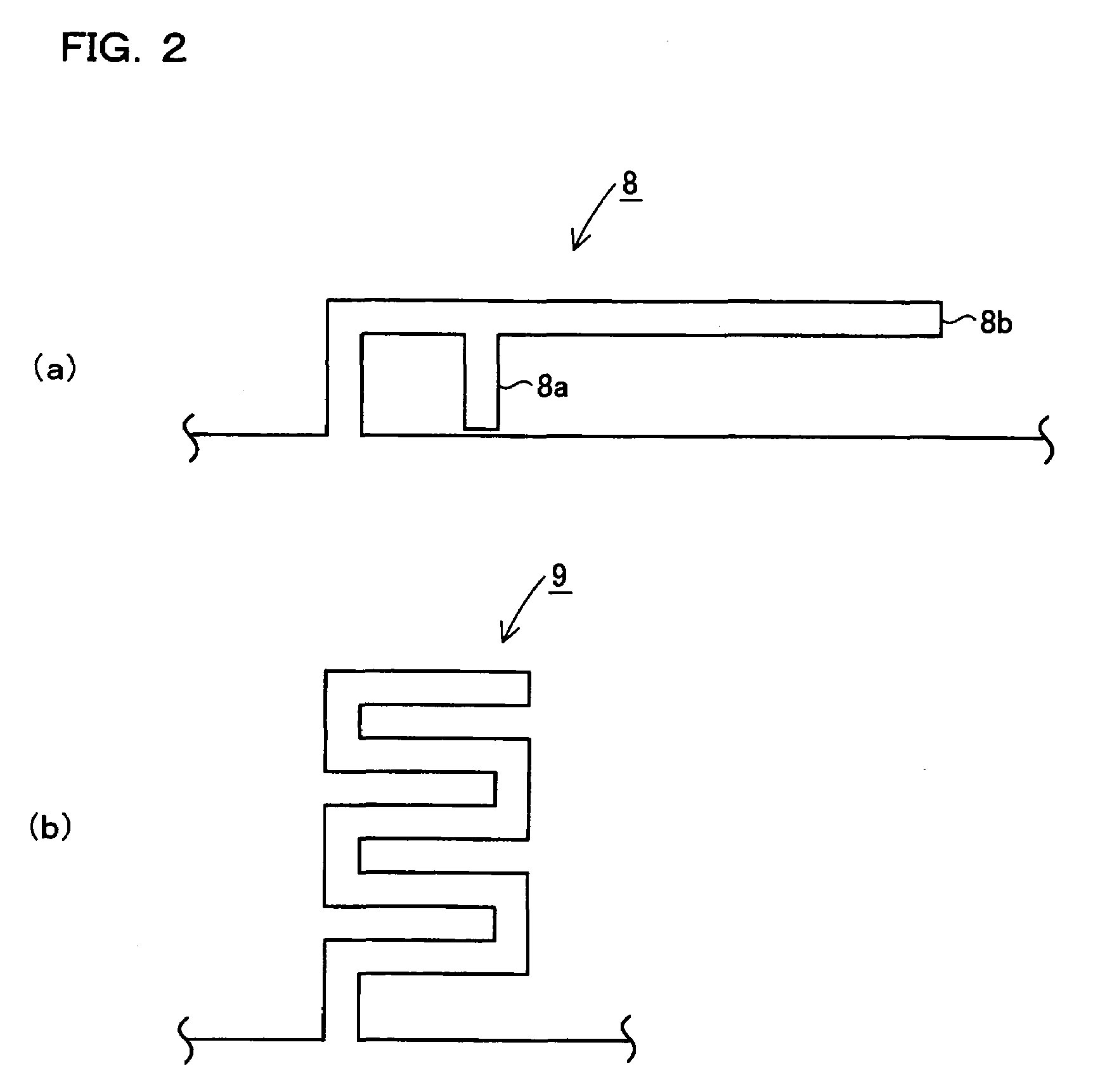

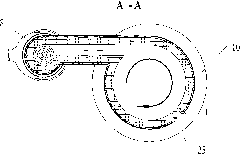

Planar antenna with multiple radiators and notched ground pattern

ActiveUS20070001911A1Reduce electromagnetic interactionCoupling degree can not be increasedSimultaneous aerial operationsRadiating elements structural formsEngineeringRadiation field

An antenna consisting of a single small and lightweight package, where each radiating element operates independently with reduced interference among the radiating elements. An integrated multi-element planar antenna includes a ground pattern 2 with a notch 2b formed at an end 2a, first radiating element 3 placed on one side of the notch 2b and equipped with a feeder 5, and second radiating element 4 placed on the other side of the notch 2b and equipped with a feeder 5. For example, inverted F antennas are used as the first radiating element 3 and second radiating element 4. The first radiating element 3 and second radiating element 4 are placed symmetrically about the notch 2b such that separation distance will be the largest at locations where their radiation fields are the highest.

Owner:LENOVO PC INT

System and method for securing digital content

ActiveUS7496540B2Intuitive experienceSimplify the purchasing processComplete banking machinesFinanceDigital rights management systemDigital content

A system is disclosed for a digital rights management system which enforces license rights by incorporating a decryption key in a license rights package that further includes an account number associated with a primary consumer. The digital rights management system also includes a mechanism for renewing / updating the license by charging the account number associated with a primary consumer. This way, the consumer may transfer the license rights package along with the digital content to any personal devices he likes but he is discouraged from freely disseminating the license package as uses by other consumers will be debited against his package or, if renewed / extended, charged against his account.

Owner:NETCRACKER TECH SOLUTIONS

Planar antenna with multiple radiators and notched ground pattern

ActiveUS7289068B2Reduce electromagnetic interactionCoupling degree can not be increasedSimultaneous aerial operationsRadiating elements structural formsEngineeringRadiation field

Owner:LENOVO PC INT

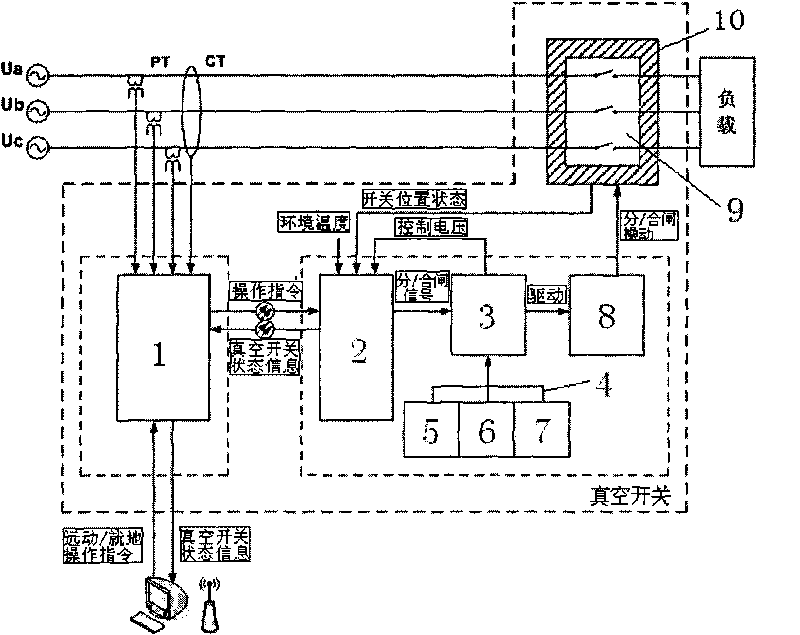

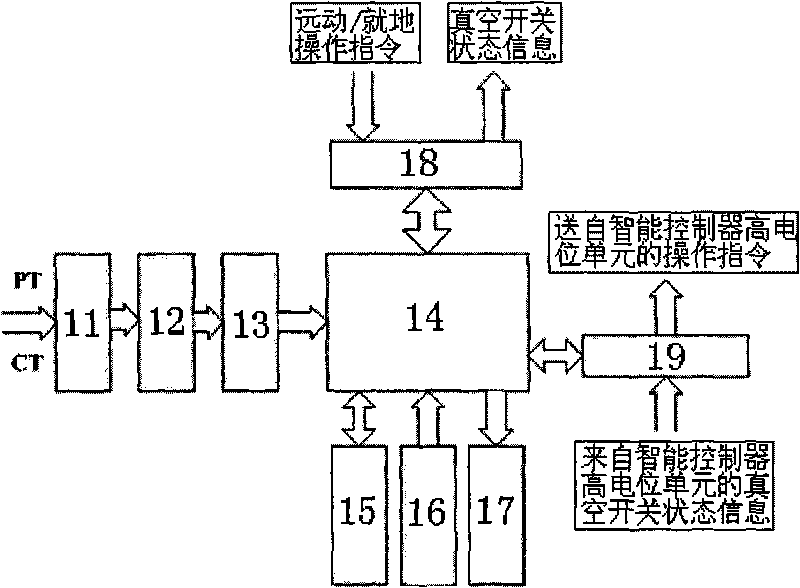

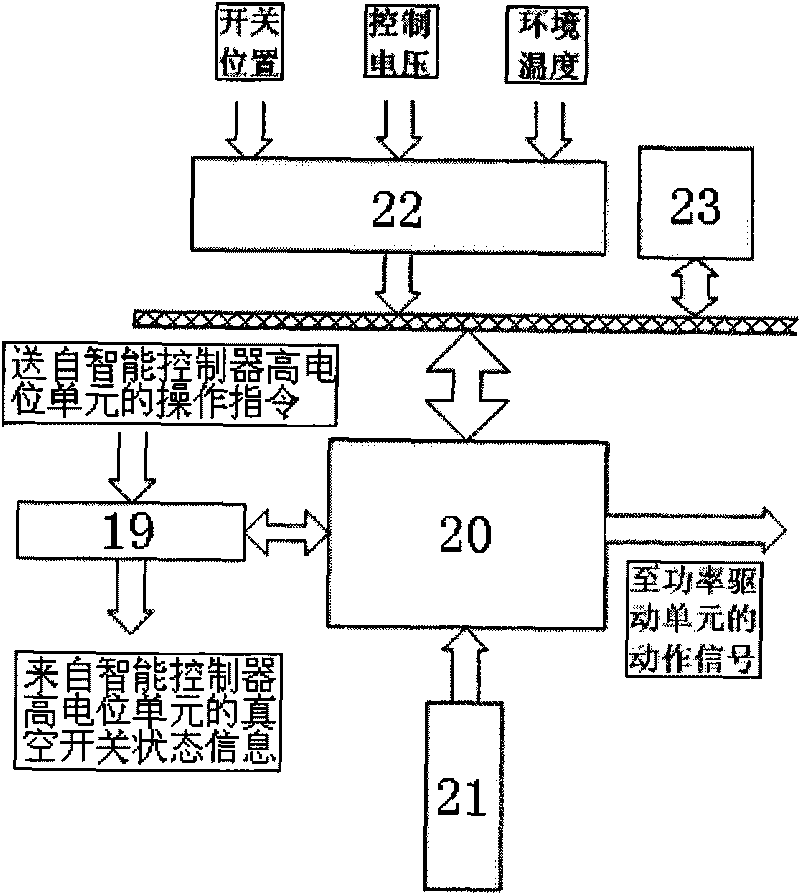

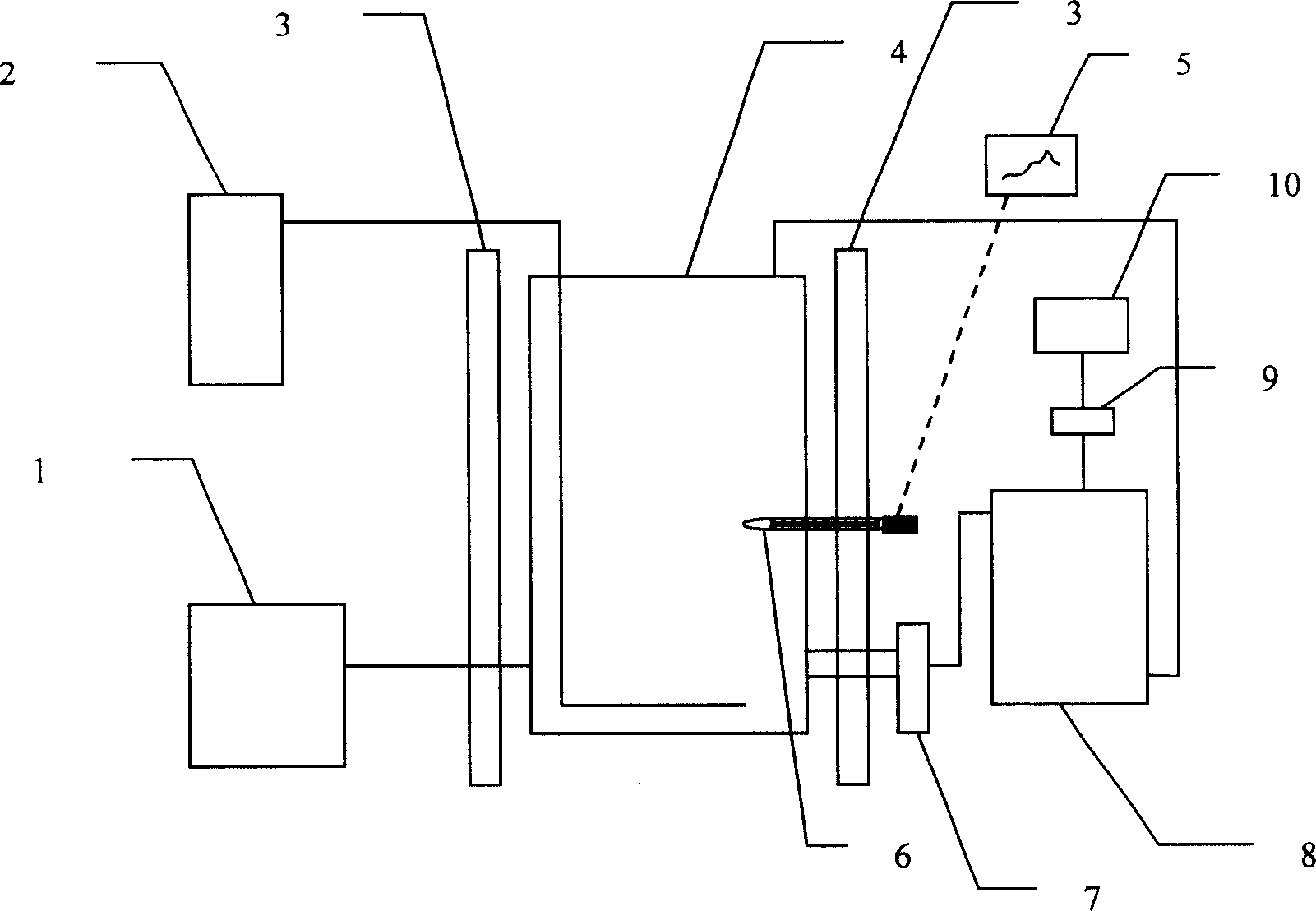

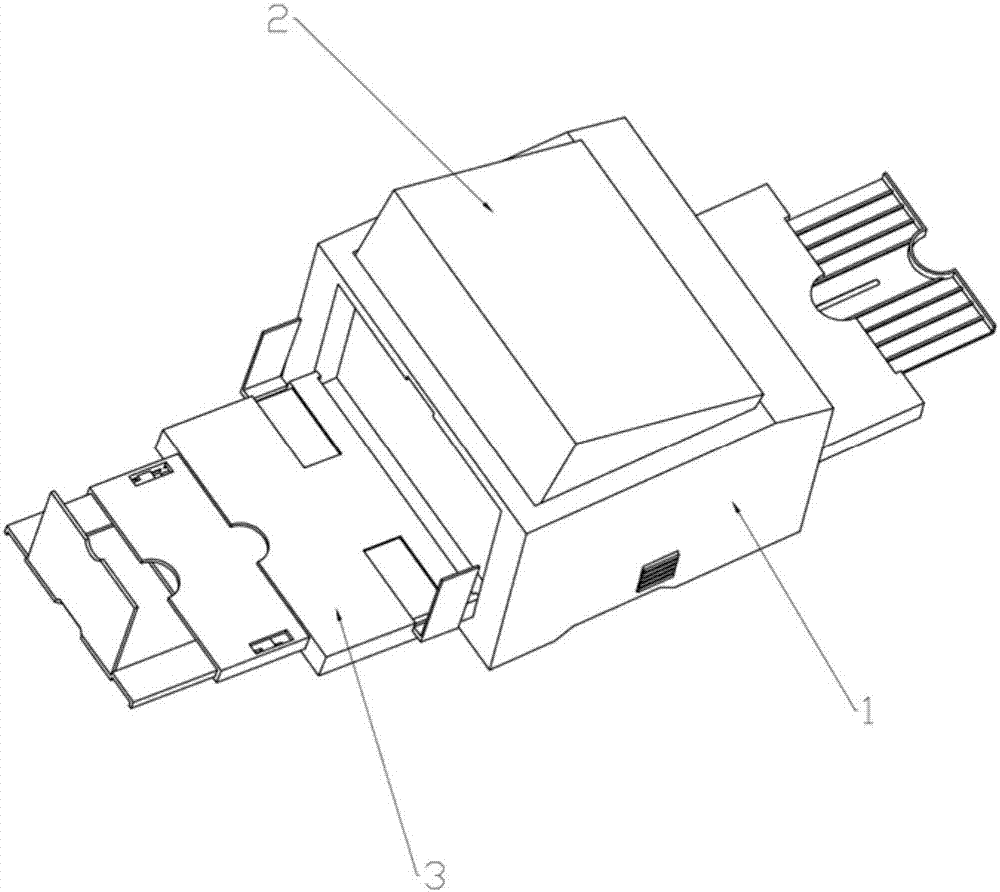

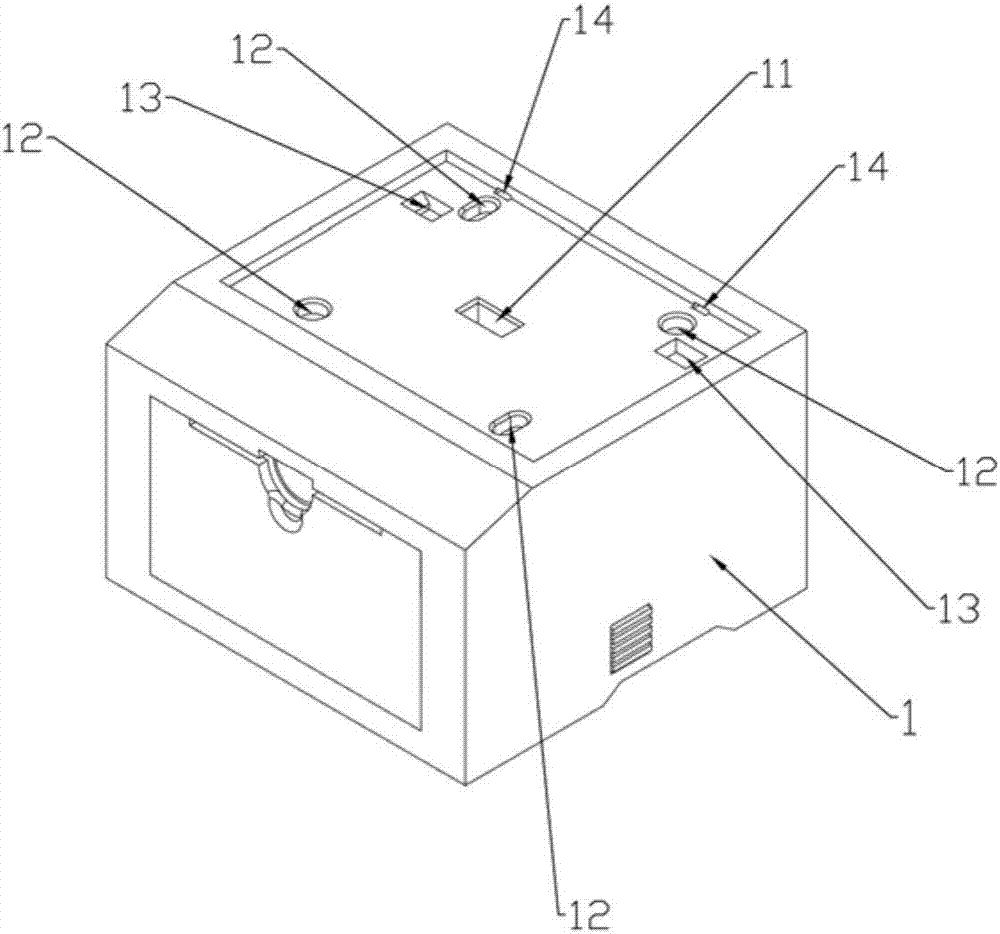

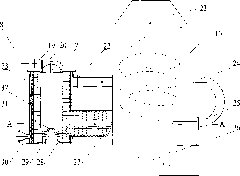

Light-operated modularization intelligent vacuum switch with phase-selecting function

ActiveCN101728114AReduce operating transientsImprove stabilityHigh-tension/heavy-dress switchesAir-break switchesAnti jammingComputer module

The invention provides a light-operated modularization intelligent vacuum switch with the phase-selecting function, comprising an intelligent phase-selecting controller low-potential unit, a high-potential unit, a power driving unit, a multi-way energy-acquiring operating power system, a permanent magnet actuating mechanism, a vacuum arc extinguishing chamber, an outer insulating system, and the like. A DSP signal processor with high performance and flexible control technique are adopted to rapidly and accurately judge the optimum switching phase of the switch for reliable operation; an optical control interface is adopted to realize high-pressure and low-pressure isolation, simplify the insulating structure and ensure strong anti-jamming ability; a novel permanent magnet actuating mechanism is adopted to ensure simple structure, flexible control and high reliability; and a novel reliable power source scheme with a multi-way energy-acquiring operating power system for acquiring energy by current, voltage and low potential is adopted. According to the requirement, series-connected and parallel-connected building block combination can be carried out on the light-operated modularization intelligent vacuum switch with the phase-selecting switch so as to realize the intelligent vacuum switch with higher voltage grade.

Owner:STATE GRID ELECTRIC POWER RES INST

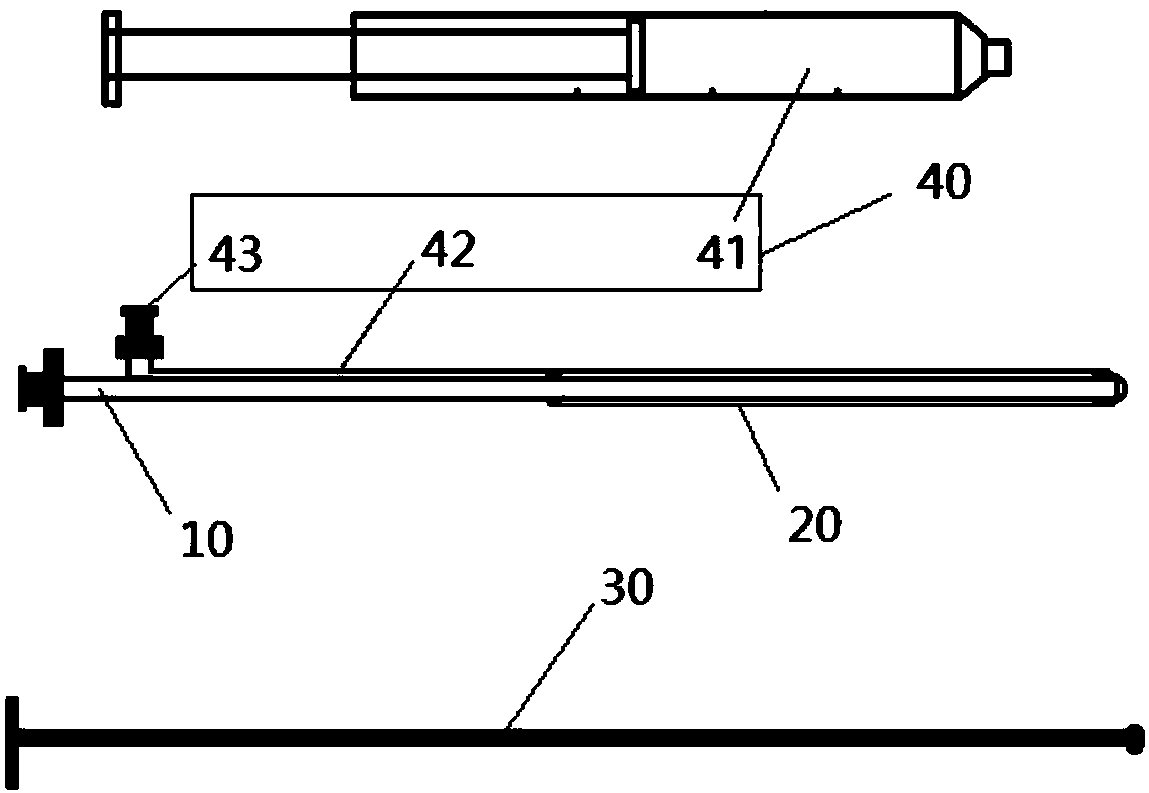

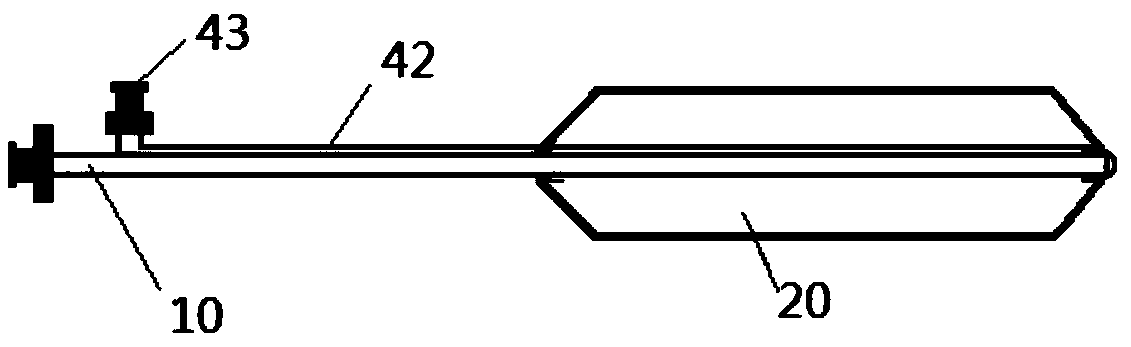

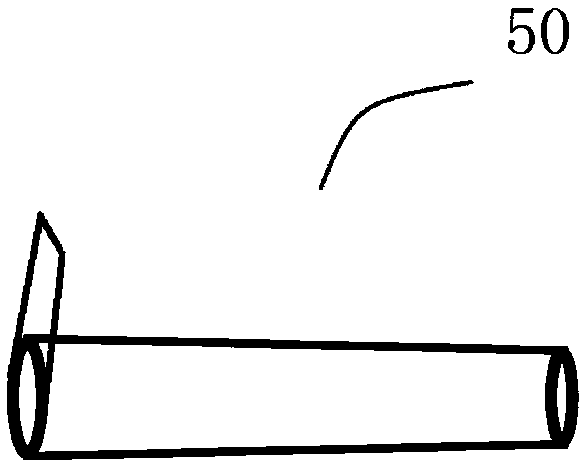

Brain operation expander and brain channel establishing method using same

The invention relates to a brain operation expander and a brain channel establishing method for brain operation under neuroendoscopy using the brain operation expander, and relates to the technical field of medical treatment. A technical scheme includes through matching length of a sacculus with length of a brain spatula, the length of the brain spatula being required length of a brain channel, the sacculus can be sent to proper depth in one time to make the sacculus expand. The length of the sacculus satisfies length requirement of the whole brain spatula, that is, establishment of the brainchannel can be completed in one time. Compared with a method in the prior art that a sacculus gradually drives the brain spatula to go forward step by step through repeated expansion and contraction,operation time is shortened, and meanwhile brain tissue protection is realized to the maximum extent, so as to provide guarantee for optimal rehabilitation.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

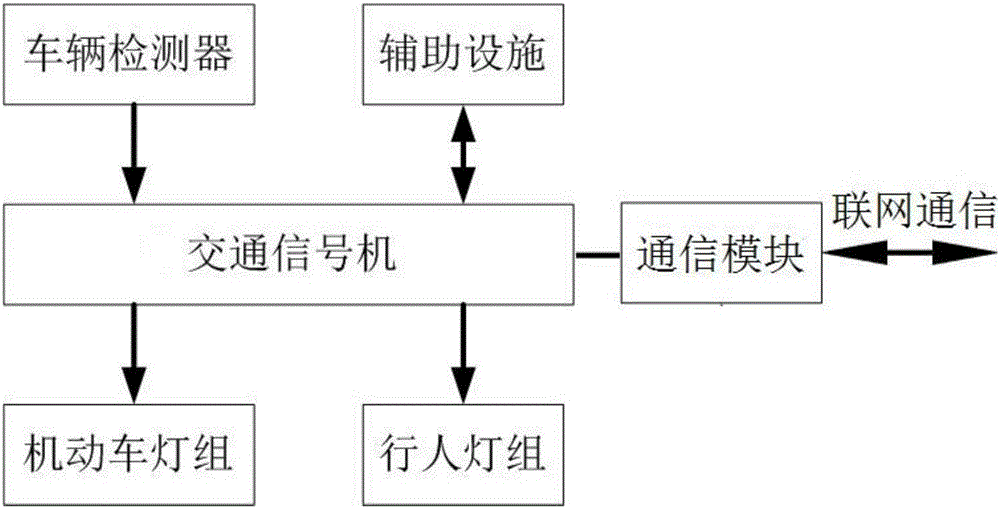

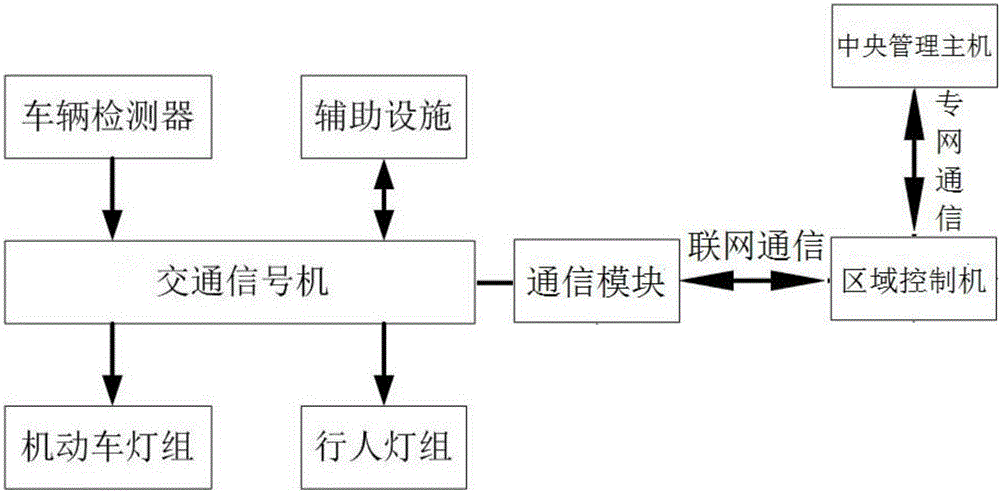

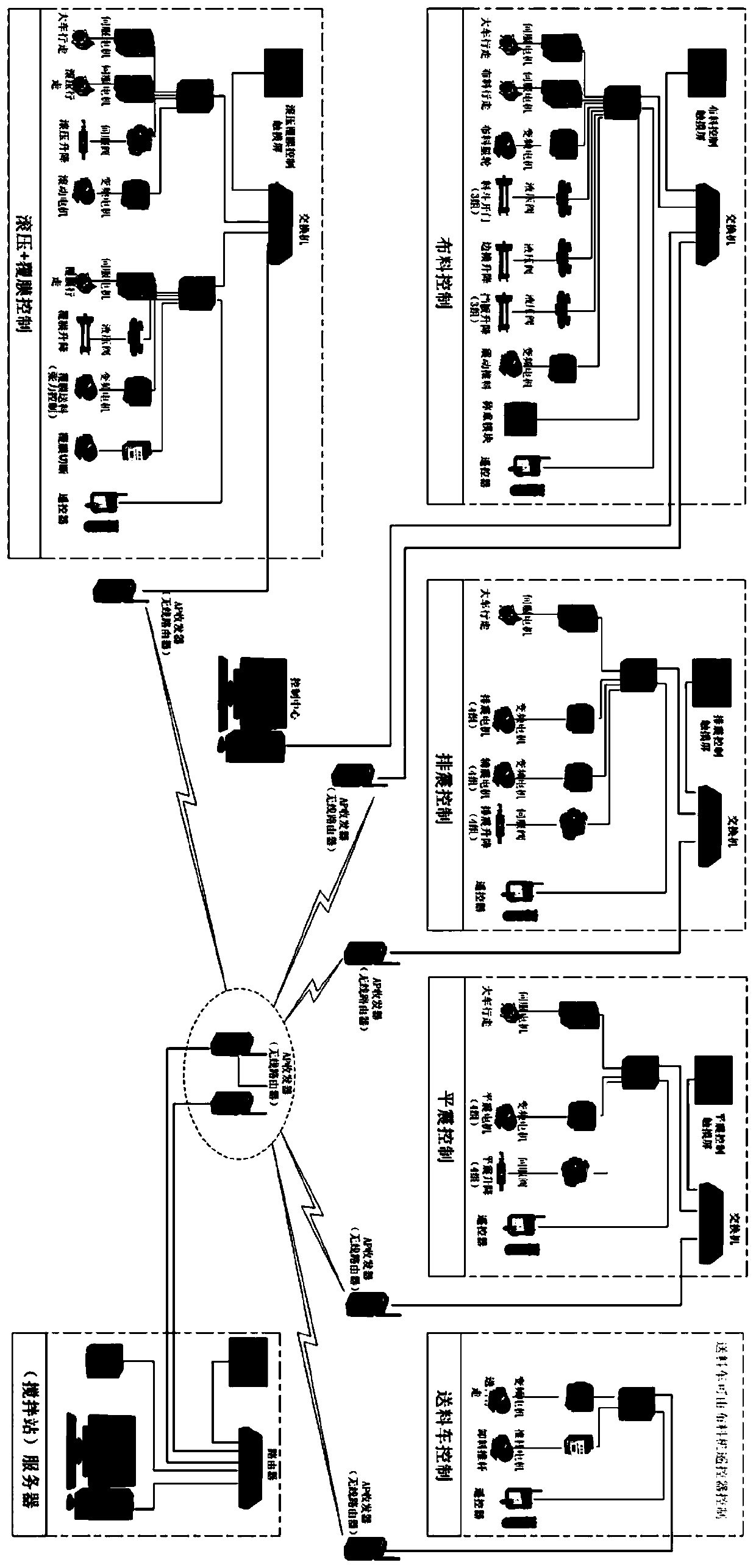

Single-point traffic signal control system and area control system thereof

PendingCN106781548ARealize partition integration controlReasonable regulation of traffic signalsControlling traffic signalsControl systemVehicle detector

The invention provides a single-point traffic signal control system and an area control system thereof. The single-point traffic signal control system comprises a traffic signal controller, a signal lamp, a vehicle detector and a communication module; the signal lamp and the vehicle detector are respectively in wire connection with the traffic signal controller through a signal line, the signal lamp and the vehicle detector are respectively arranged in an out-field traffic intersection, and the traffic signal controller is arranged in a lateral sidewalk idle area of the out-field traffic intersection; the communication module is connected with the traffic signal controller through a cable; the traffic signal controller can be communicated with outside equipment through the communication module. By the arrangement, modern control of traffic signals at various intersections is realized.

Owner:广州市交通设计研究院有限公司

Method for automatically generating 3D face according to photo

InactiveCN104680574AEasy to operate independentlyEffective interactionCharacter and pattern recognition3D modellingGeneration processAnimation

The invention relates to a method for automatically generating a 3D face according to a photo. The method is characterized by comprising the following steps: a face material needing to be processed is chosen by a user to generate a 3D face image; then, adjustment, matching and detail modification are performed on the 3D face image; and finally, animated facial expressions are imported into the 3D face image and stored. Thus, a 3D face image can be generated for a user step by step by use of a photo, and the details of each part can be adjusted after generation. The method can cooperate with subsequent procedures, a generated face has a variety of preset facial expressions, and effective 3D face image interaction can be performed. Moreover, the whole generation process is simple and easy to process, the data burden on processing equipment is not increased, and the method is easy for users to operate independently.

Owner:SNAIL GAMES

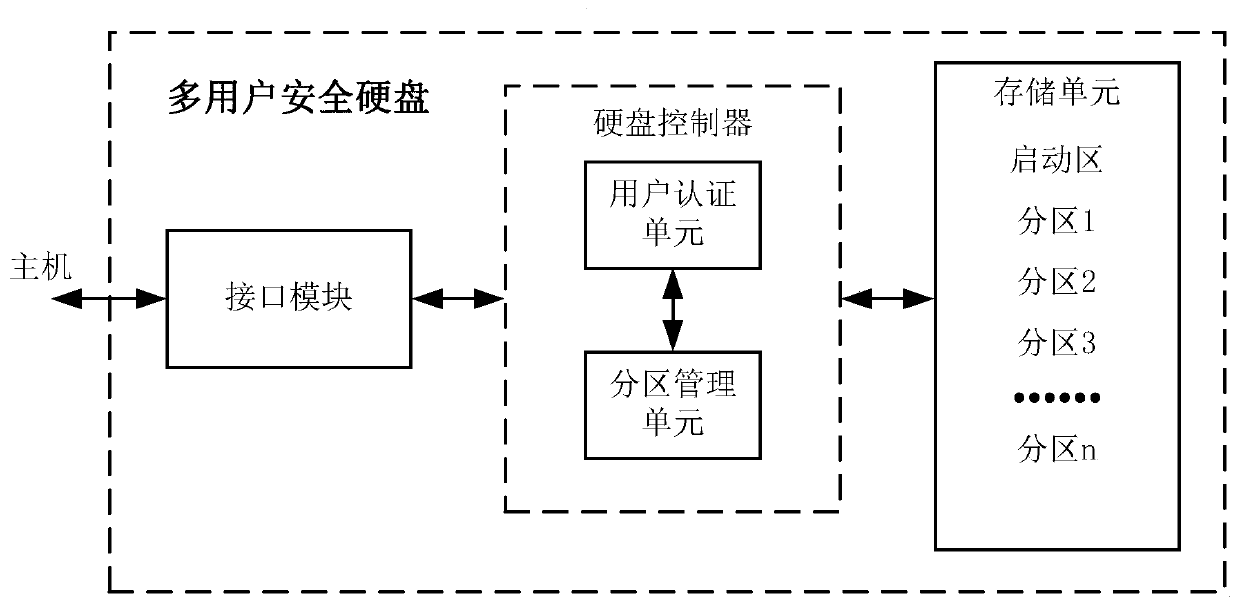

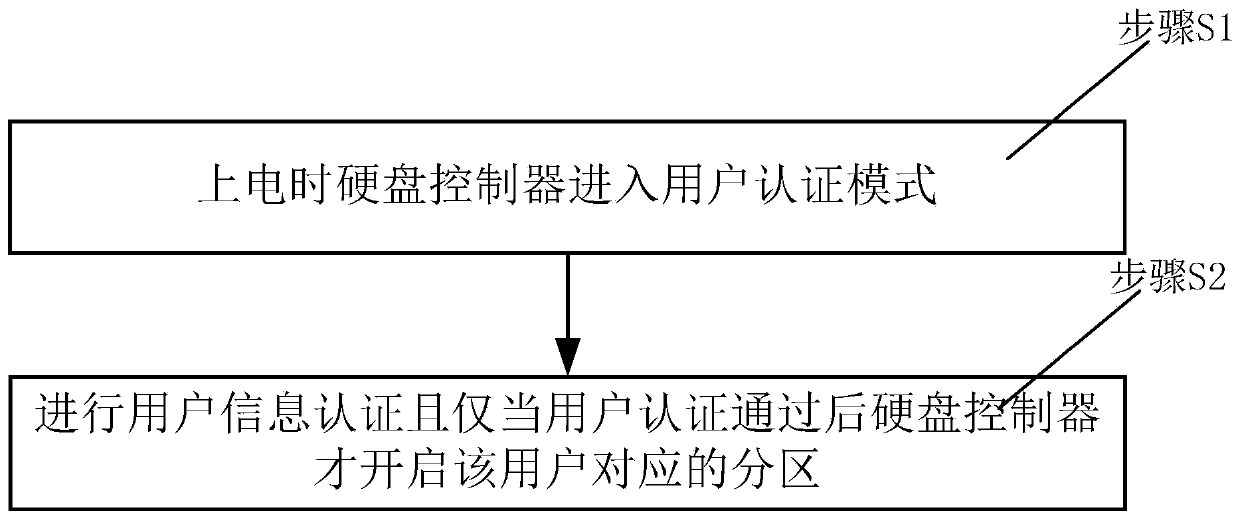

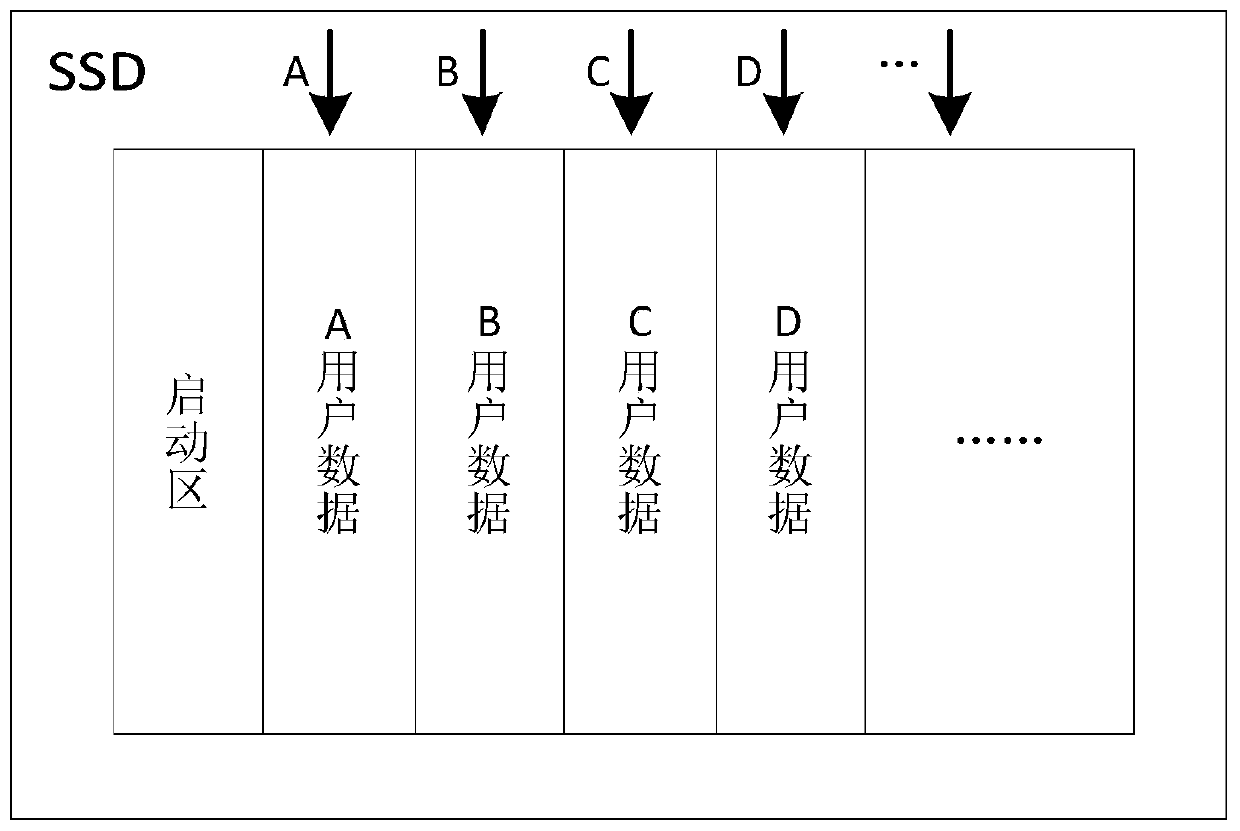

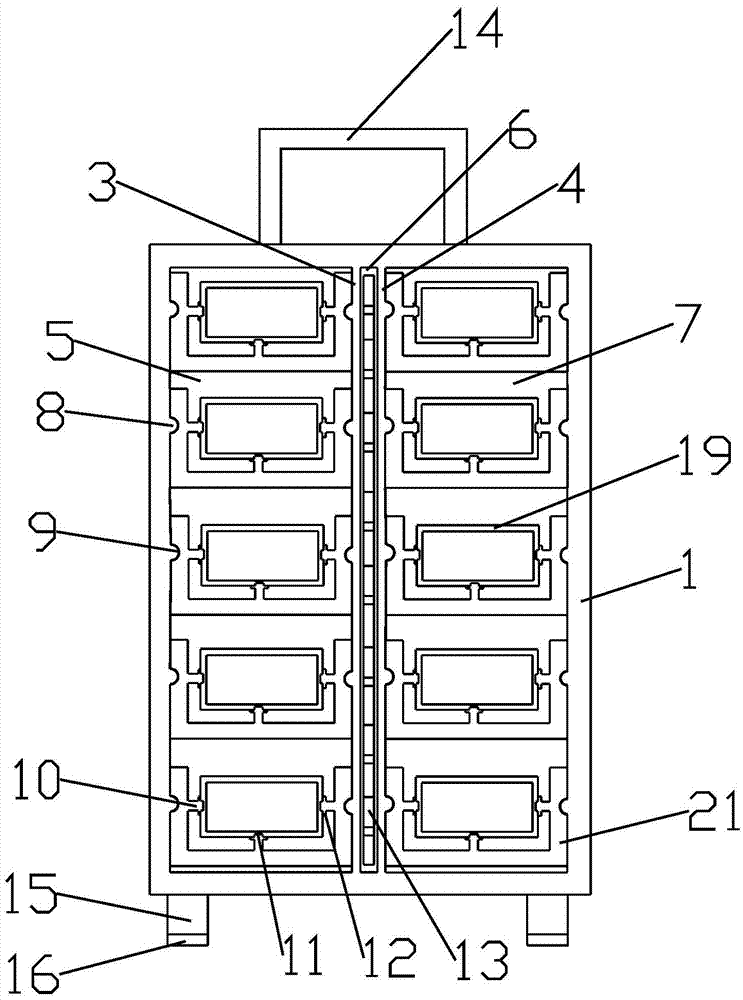

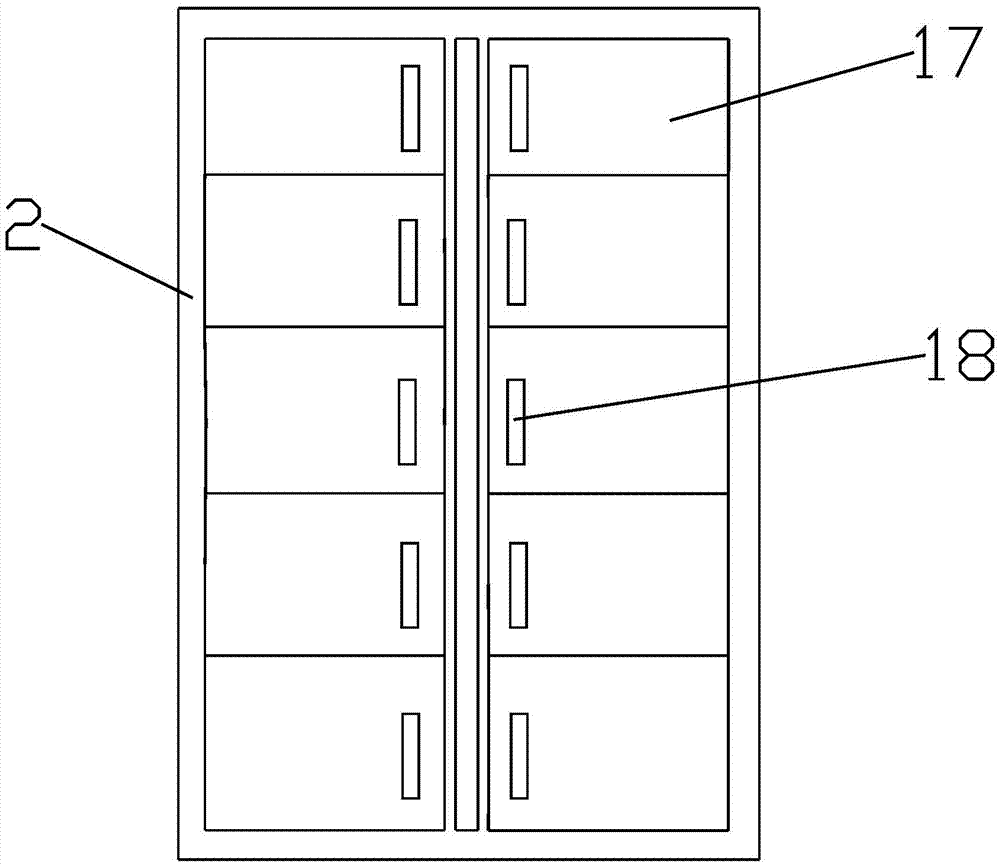

A multi-user security hard disk and a control method thereof

InactiveCN109711206AReduce the risk of attackEasy to operate independentlyInternal/peripheral component protectionManagement unitDisk controller

The invention discloses a multi-user security hard disk and a control method thereof, the multi-user security hard disk at least comprises an interface module, a hard disk controller and a storage unit, and the interface module is used for carrying out data communication with a host; the storage unit opens up a plurality of independent partitions for multi-user data storage; the hard disk controller is connected with the interface module and the storage unit, is used for controlling the work of the storage unit according to an instruction of the host, and at least comprises a user authentication unit and a partition management unit, and the user authentication unit is used for carrying out user information authentication and sending authentication result information to the partition management unit; and the partition management unit is used for managing the corresponding partition of the storage unit according to the authenticated user information, so that the hard disk controller canonly perform read-write operation on the partition. Compared with the prior art, the physical isolation of each user data storage area is realized through the bottom chip of the storage equipment, sothat the data security performance is greatly improved.

Owner:SAGE MICROELECTRONICS CORP

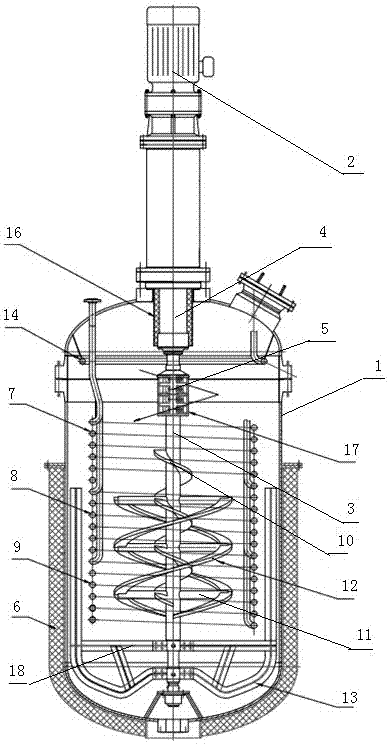

Polymeric reactor for polyphenylene sulfide

PendingCN107570086AGuaranteed tightness and stabilityReduce exchangePressurized chemical processChemical/physical/physico-chemical stationary reactorsTemperature controlManufacturing technology

The invention relates to the technical field of chemical mechanical stirring reactor manufacturing and specifically relates to a polymeric reactor for polyphenylene sulfide. The polymeric reactor comprises a kettle body, a stirring motor, a stirring shaft, a stirrer and a magnetic coupling sensor, wherein the stirring motor is arranged above the kettle body; an output shaft of the stirring motor is connected with a magnetic coupling driver inserted into the kettle body; the upper end of the magnetic coupling driver is connected with the stirring motor; the lower end of the magnetic coupling driver is connected with the stirring shaft through a coupler; the stirrer is arranged on the stirring shaft; the polymeric reactor is characterized in that an external quick temperature control mechanism, an internal auxiliary temperature control mechanism and an anti-adhesion stirring mechanism are arranged on the kettle body. The polymeric reactor has the advantages of simple structure, convenience in cleaning, stable and easy controllable reaction temperature, benefit in continuous operation high efficiency, high yield, and the like.

Owner:WEIHAI CHEM MACHINERY

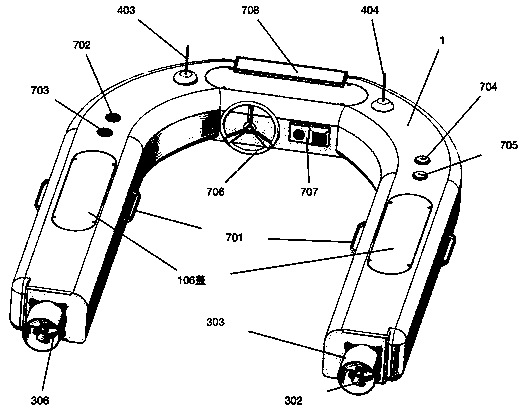

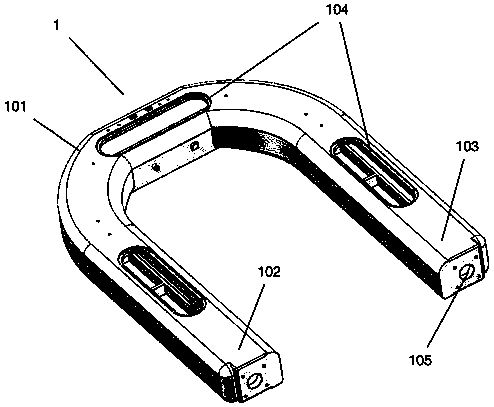

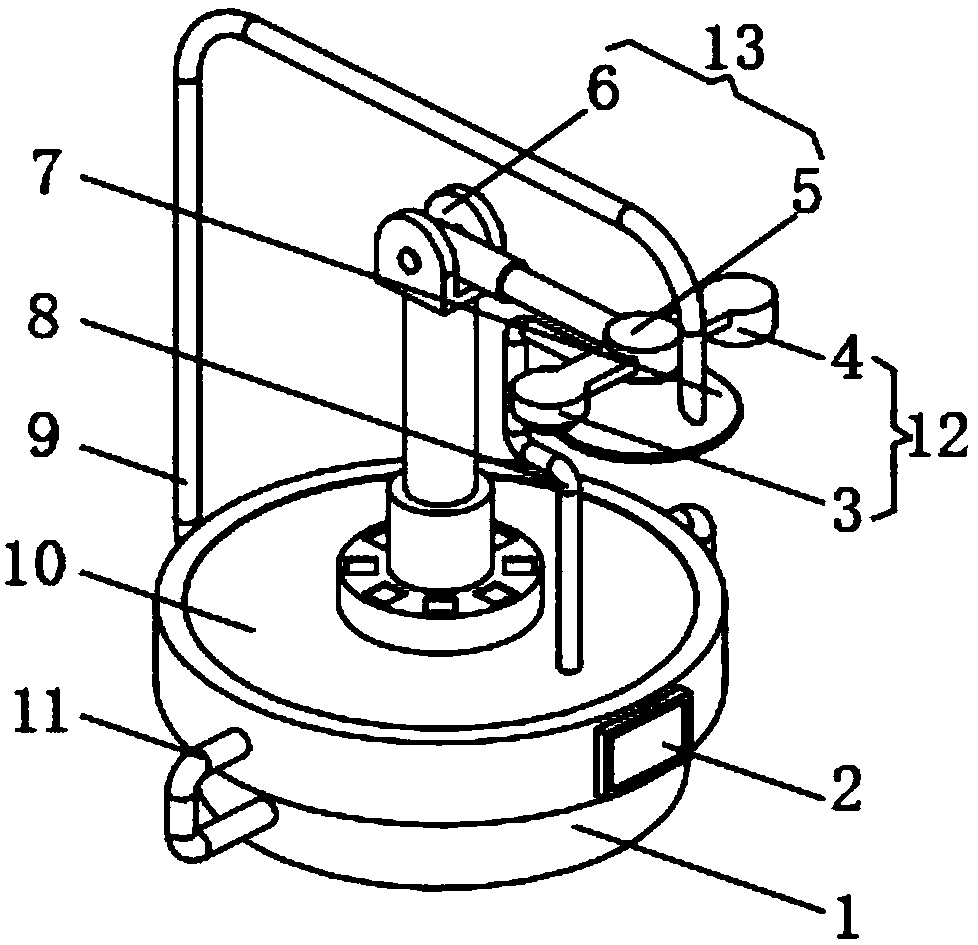

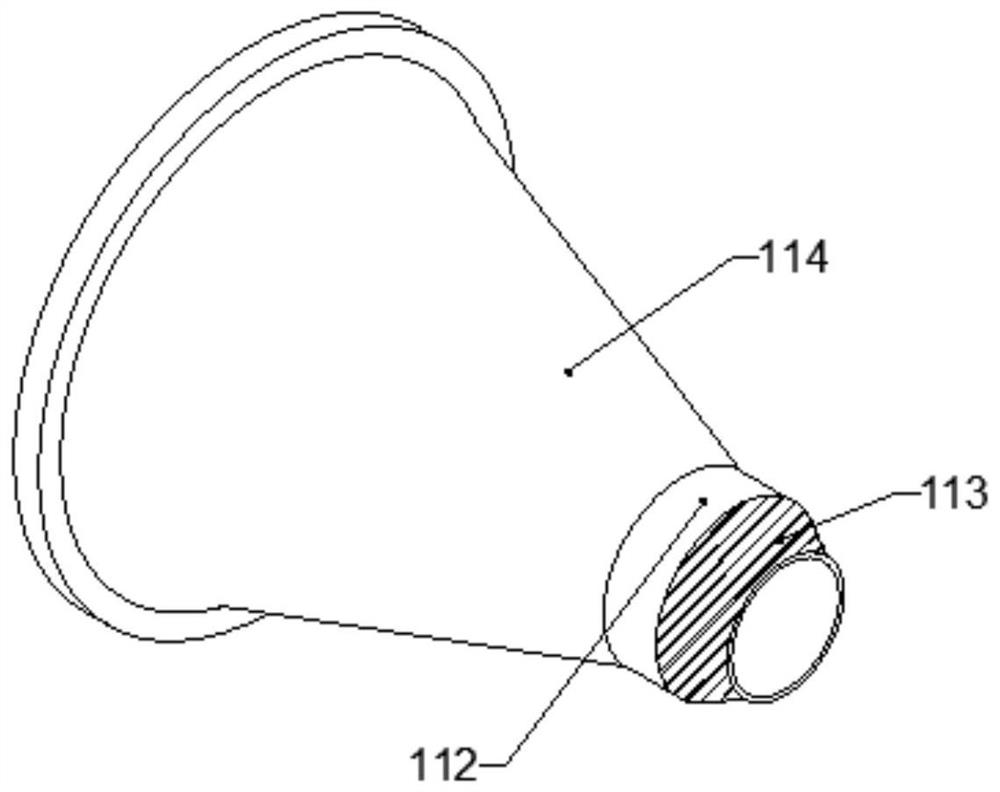

Interactive intelligent life buoy

PendingCN109760800ASpeed up searchEasy to operate independentlyLife-savingCommunications systemControl system

The invention relates to an interactive intelligent life buoy which comprises a life buoy body, a control system, power systems, a communication system, a detection system, an accumulator and an interaction device, wherein the life buoy body is a U-shaped hollow shell, multiple slotted holes are formed in the upper end face of the life buoy body, and a sealing cover is arranged in each slotted hole; the control system serving as a control core is arranged inside the life buoy body; the power systems are symmetrically arranged in supporting legs of the life buoy body; host components of the communication system are arranged inside the life buoy body; a detection component is arranged on the top of the life buoy body; the accumulator is arranged inside the life buoy body and provides a powersupply for electric equipment of the intelligent life buoy; and the interaction device comprises a button, a display screen and voice equipment, is arranged outside the life buoy body, and provides an interactive interface for a drowning person. The interactive intelligent life buoy disclosed by the invention is simple in structure, can automatically detect a water area target and generate a traffic channel and is conveniently operated by the drowning person, and other drowning persons can be rescued by virtue of the first drowning person.

Owner:青岛无疆技术有限公司

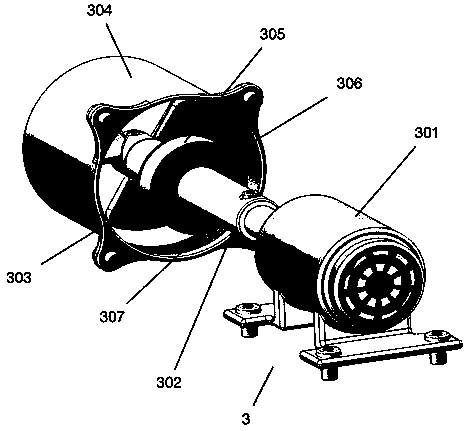

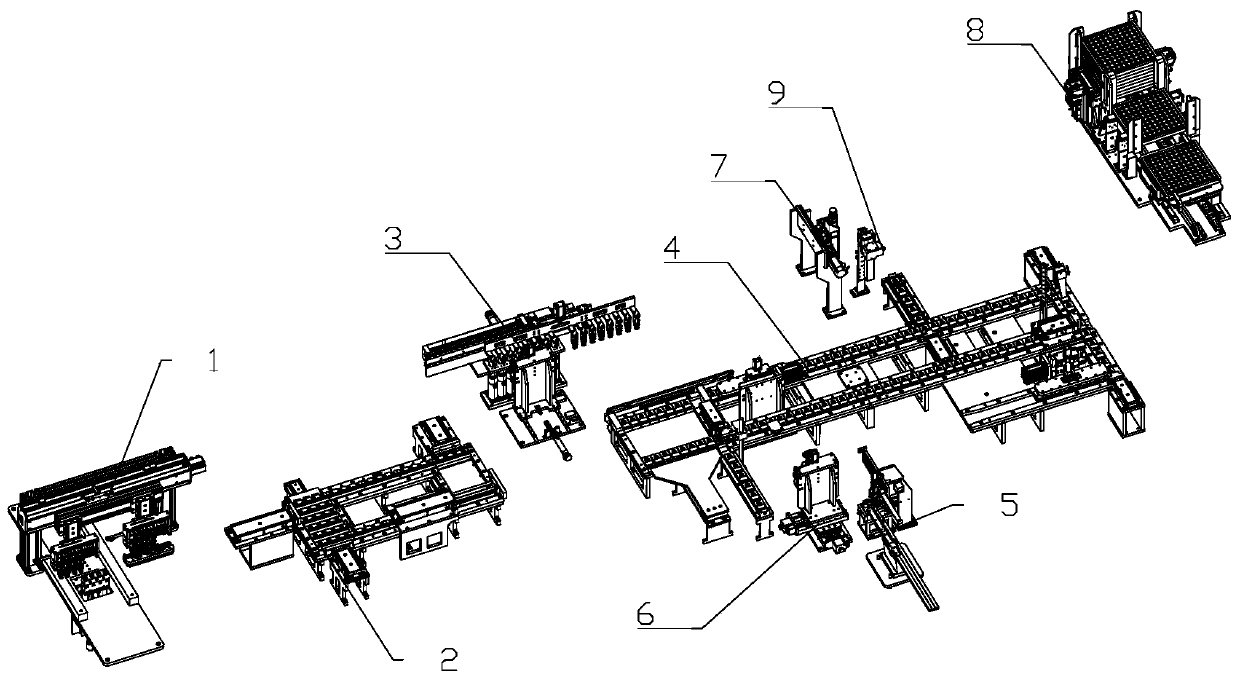

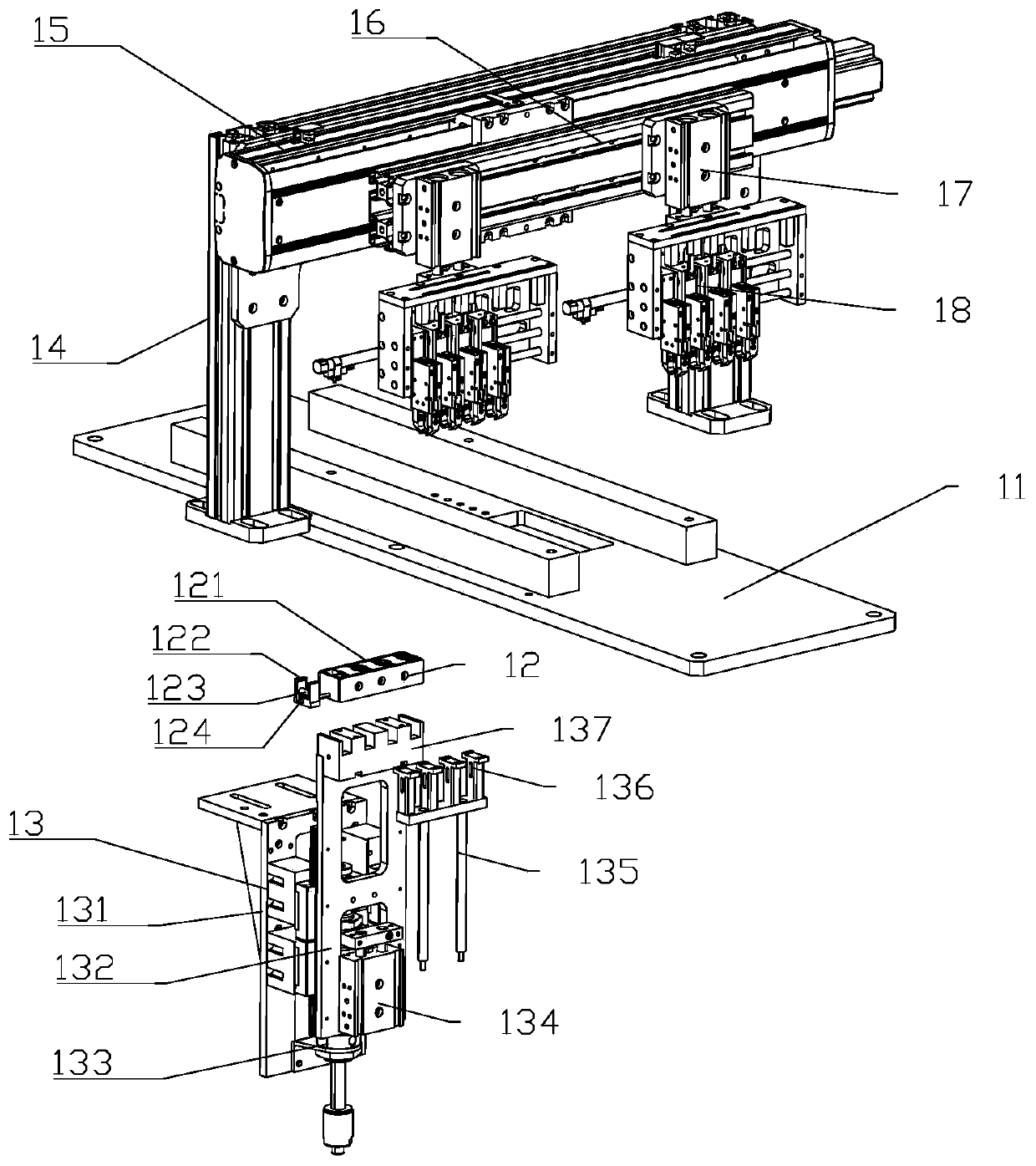

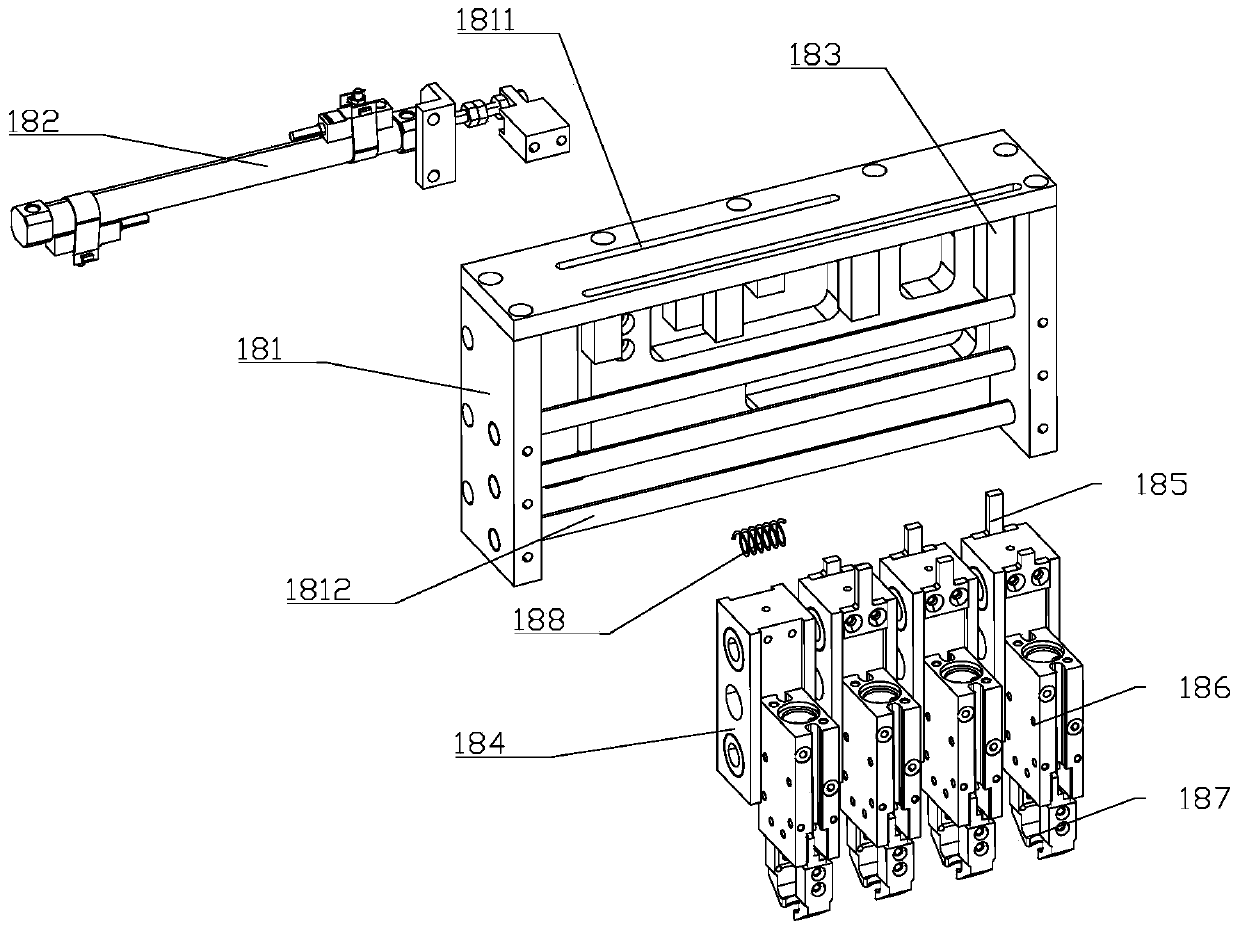

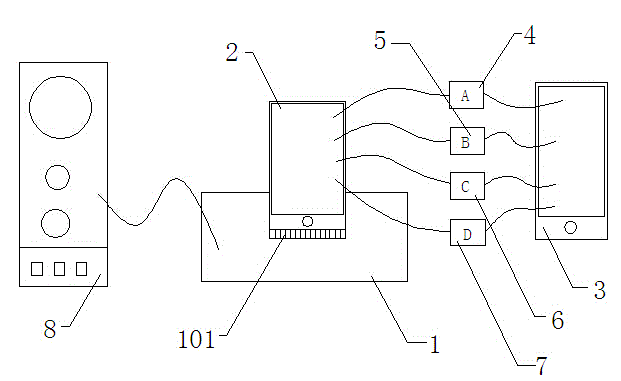

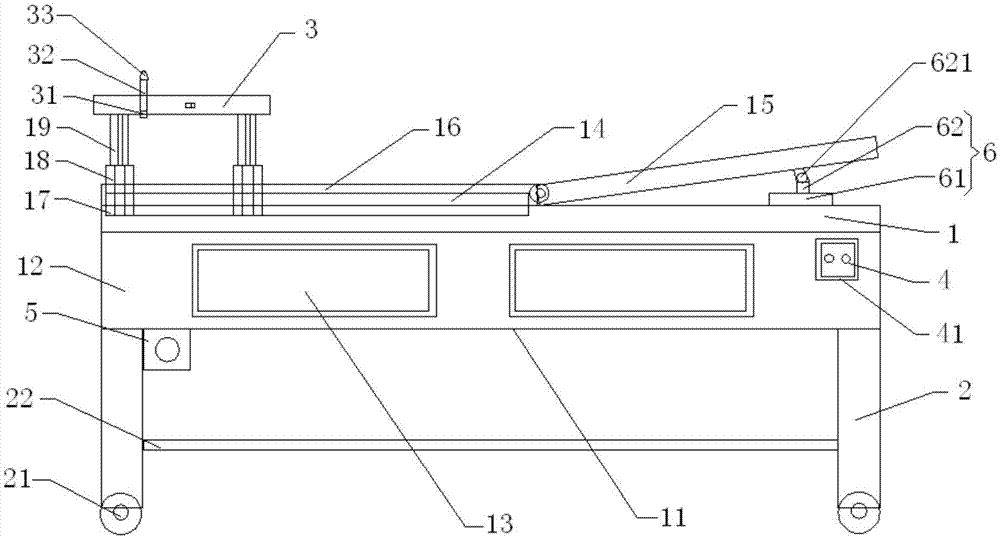

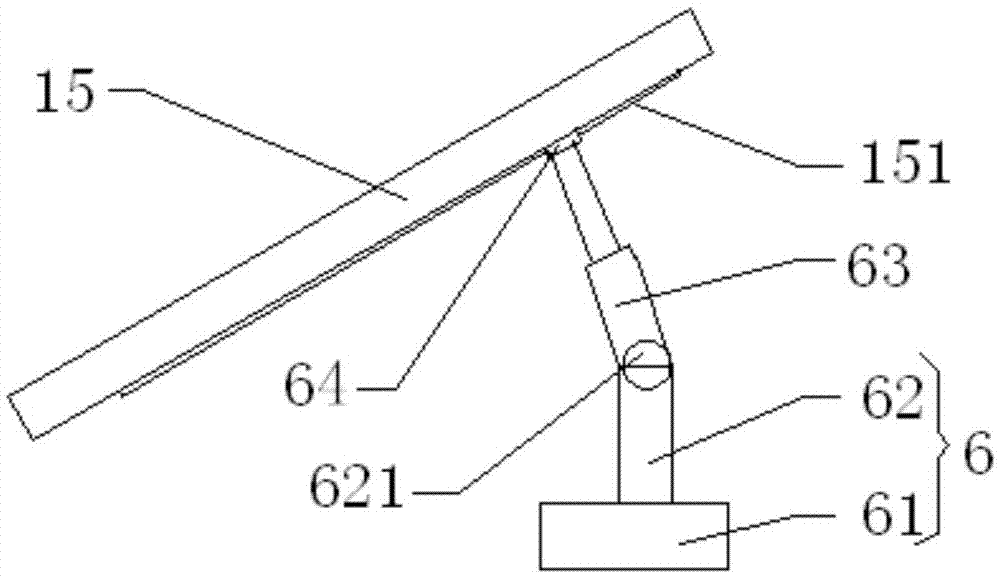

Earphone and coil body assembling device and method thereof

ActiveCN111556412AHigh positioning accuracyChange distanceEarpiece/earphone manufacture/assemblyEngineeringHeadphones

The invention relates to the technical field of earphone production. The earphone coil body assembling device comprises a rack, and a coil body feeding device, a conveying device, a carrying device, ajig circulating device, a basin stand feeding device, a dispensing device, a pressing device, a collecting device, a detecting device and a discharging manipulator which are mounted on the rack, wherein the coil body feeding device corresponds to the feeding end of the conveying device, and the carrying device corresponds to the discharging end of the conveying device. The basin frame feeding device, the dispensing device, the pressing device and the detecting device correspond to the jig circulating device. The coil body assembling device has the advantages that the mutual spacing can be adjusted during coil body feeding, and the spacing can be adjusted; the two sides of the jig loaded with the product are separated, and the jig is automatically supplemented; tray taking and stacking ofthe trays are efficient, the trays are clamped from the side, and the space is compact.

Owner:湖南和普新能源科技有限公司

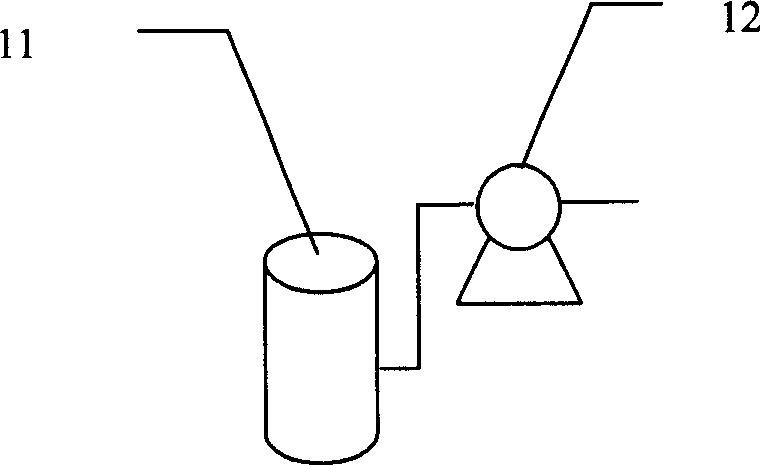

Culturing system of external light biological reactor for plant tissue cutter

InactiveCN1680535AReduce pollutionSolve practical problems caused by experimentsBioreactor/fermenter combinationsBiological substance pretreatmentsPlant tissueAir filter

An outlay plant tissue cutter optical bioreactor culture system which contains transfusion system, air transportation system, illumination system and bioreactor culture system, data processor, light-sensitive monitor, tee valve, incision system, air filter, vacuum / pressure pump. The silicone tube is the connection of the transfusion system and air transportation system to the bioreactor culture system; the outside of it is illumination system; and the other side is light-sensitive monitor. The invention can decrease the pollution of the incision greatly.

Owner:SHANGHAI JIAO TONG UNIV

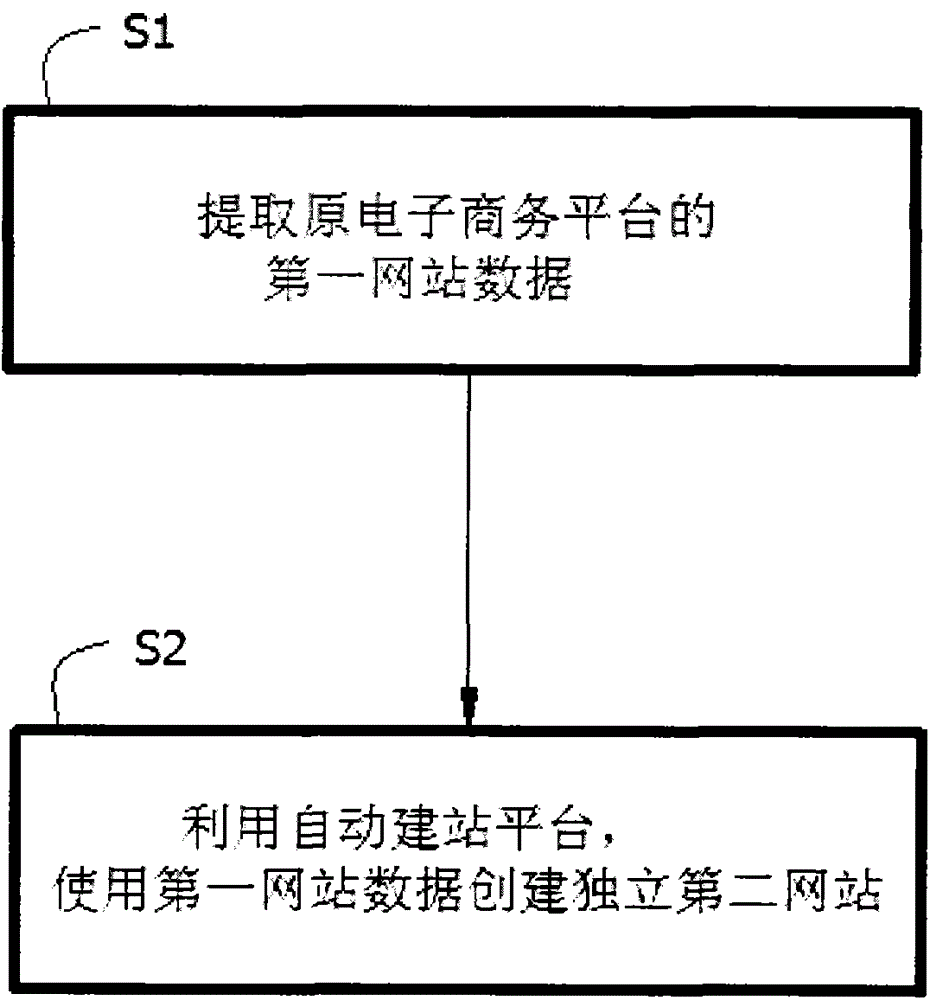

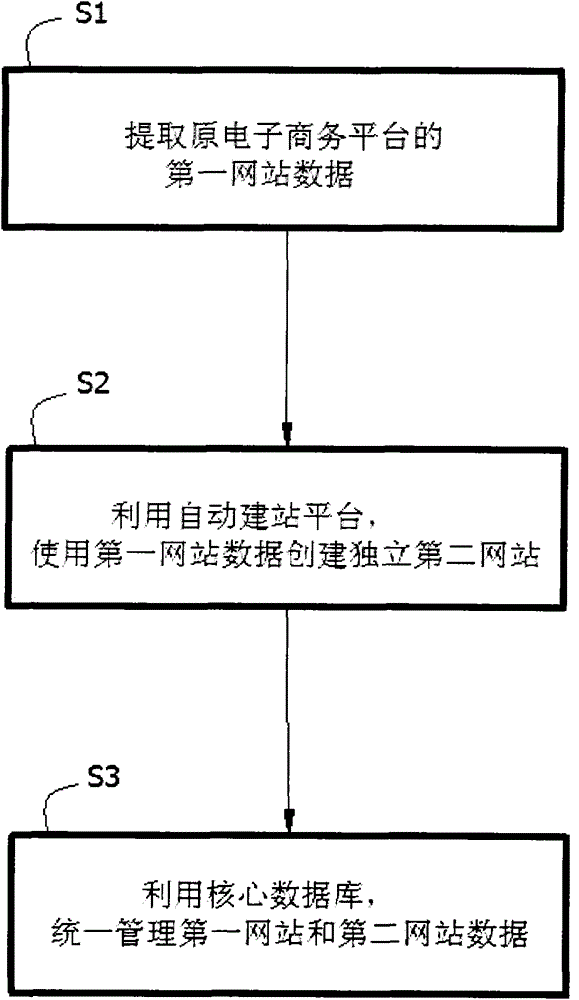

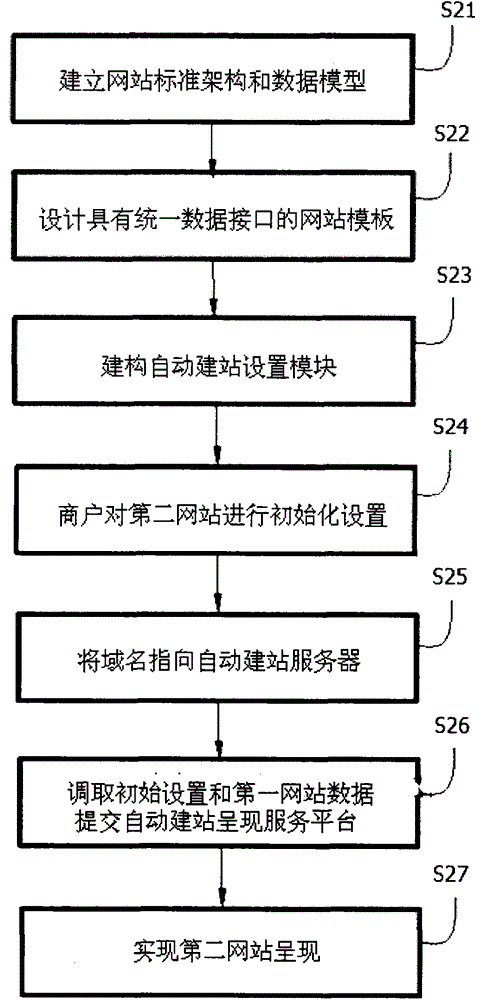

Method for creating independent website based on electronic commerce platform

The invention relates to a method for creating an independent website based on an electronic commerce platform and belongs to the Internet website creation technical field. The method of the invention includes the following steps that: S1, the data of a first website which is registered in the electronic commerce platform by a commercial tenant are extracted; S2, a second website which is presented independently is creased through utilizing the data extracted in the S1 and based on a scalable and multi-scheme automatic website establishment platform; the second website can be visited independently, and can share the data of the first website; and S3, a core database is established, and the data of the first website and the second website can be managed in a unified manner, so that the data of the first website and the second website can be shared and can be presented synchronously. According to the method of the invention, an independent enterprise website can be created conveniently through utilizing original data, and unified management and sharing of the data of the two websites can be realized, and the website establishment cost and website operation cost of the commercial tenant can be greatly decreased.

Owner:北京七品科技有限公司

Intelligent vote counting all-in-one machine

ActiveCN106952384AIntuitive feelingEasy to operate independentlyVoting apparatusPulp and paper industryComputer terminal

The invention belongs to the technical field of vote counting machines, and discloses an intelligent vote counting all-in-one (AIO) machine. The AIO machine comprises a high speed reader, a data processing terminal, which is arranged above the high speed reader, and a paper out chamber arranged in the paper outlet of the high speed reader; wherein the paper out chamber has a telescoping structure and comprises lateral plates. Compared with the prior art, the AIO machine has the advantages that the data processing terminal and the high speed reader are integrated, the integration degree is high, the stability is strong, and more direct sense and better operation experience are provided for the users. Furthermore, the paper out chamber is provided with a telescoping plate and a baffle plate, the length of the telescoping plate can be adjusted according to the size of a vote, and thus the AIO machine is suitable for various votes. Moreover, the paper out chamber can be folded and stored in a groove, the occupied space is small, and the storage is convenient. Two sides of the paper out chamber are provided with a lateral plate along the paper out direction, the votes can be guided, and the disorder of votes can be avoided. The lateral plates are positioned by an L shaped plate, the structure is simple, the cost is low, and the folding and unfolding are simple and labor-saving.

Owner:CHENGDU CAS INFORMATION TECH CO LTD

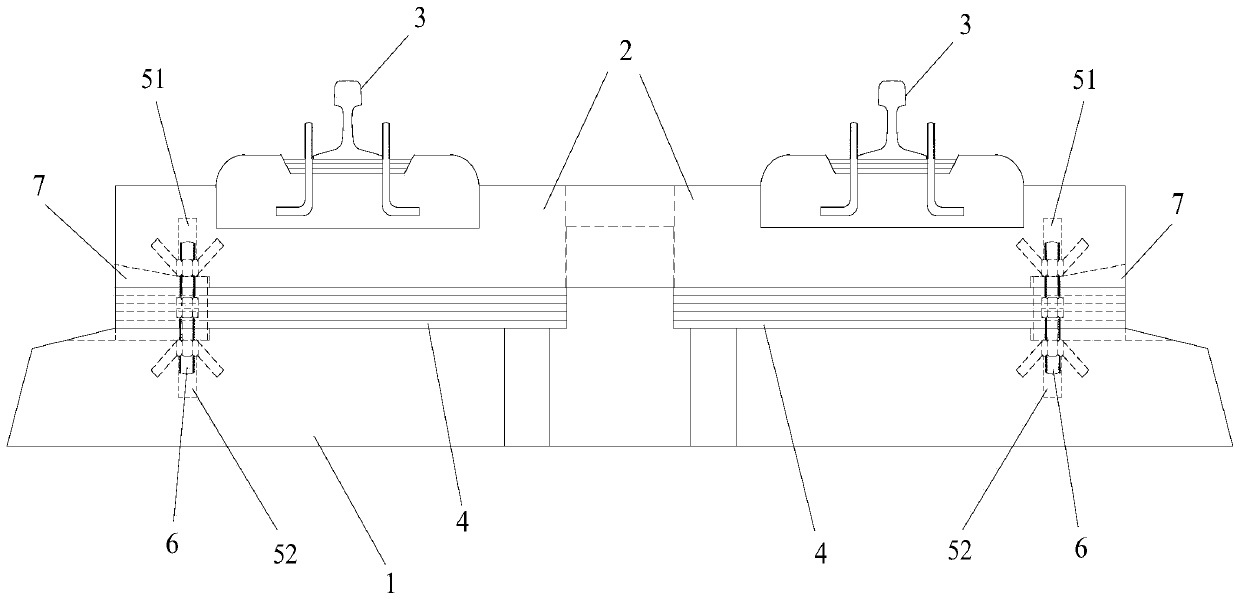

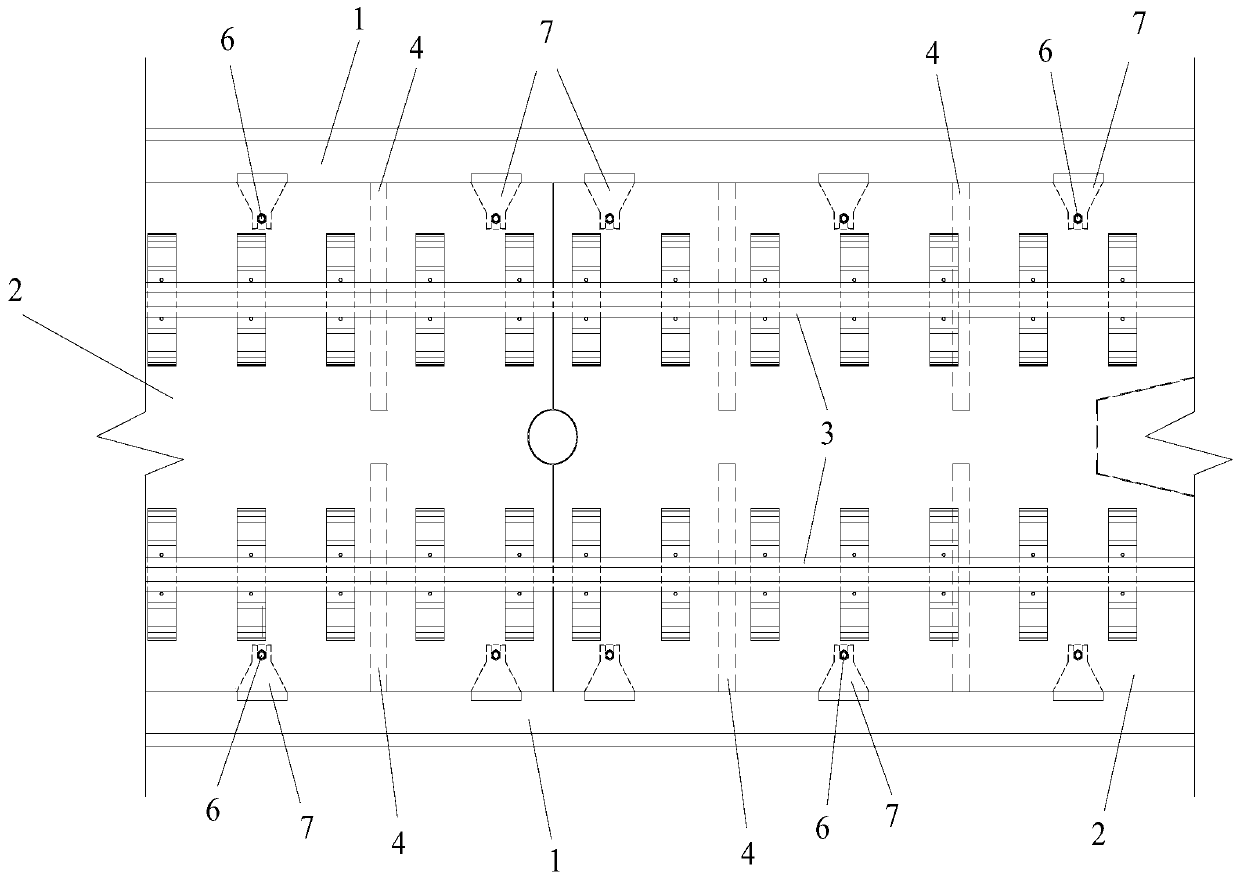

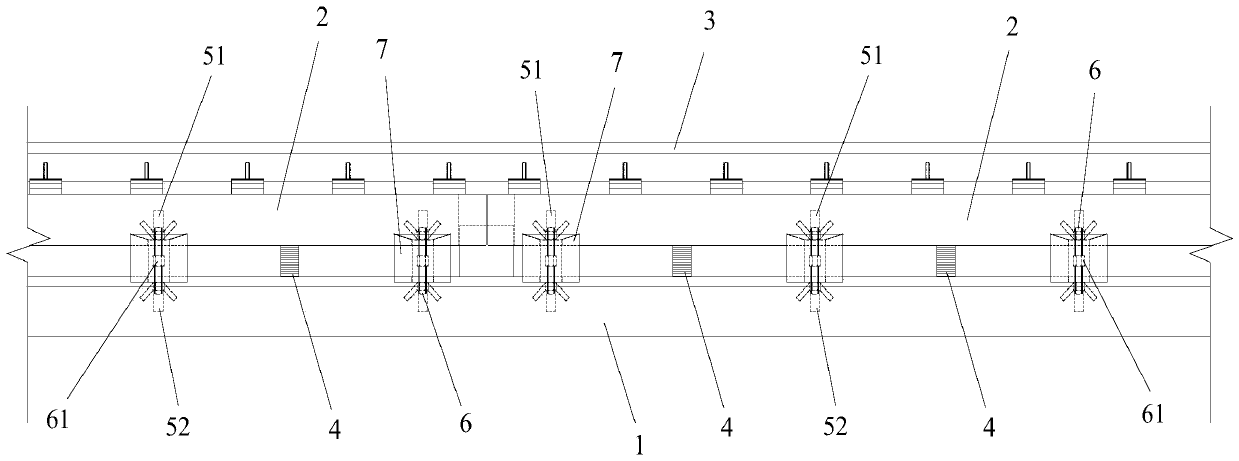

Liftable ballastless track structure and adjustment method thereof

PendingCN110565448AGuaranteed running speedImprove securityBallastwayStructural engineeringLimit value

The invention discloses a liftable ballastless track structure and an adjustment method thereof. According to the liftable ballastless track structure, a left-handed nut and a right-handed nut on eachtransfer bar are relatively close to each other or relatively far away from each other by driving an adjusting nut, and thus, the distances between a track plate connected to the left-handed nut anda base and between a track plate connected the right-handed nut and the base are increased or decreased; and a gap between each track plate and the base is supported by arranging a cushion block. Theliftable ballastless track structure can break through the adjustable range limiting value of the prior art, effectively adapts to a large number of continuous arching or settlement deformation in special areas such as road cutting in expansive rock and soil areas, has high adjustment accuracy, is especially suitable for the accuracy control of uphill and downhill lines and curved lines, effectively reduces the speed-limiting operation sites of railways, ensures the speed of railway operation, increases the safety factors of railway operation, reduces the frequency of outage for overhauling, saves operation and maintenance costs, is convenient for initial installation operation and elevation adjustment operation, and has good application prospect.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

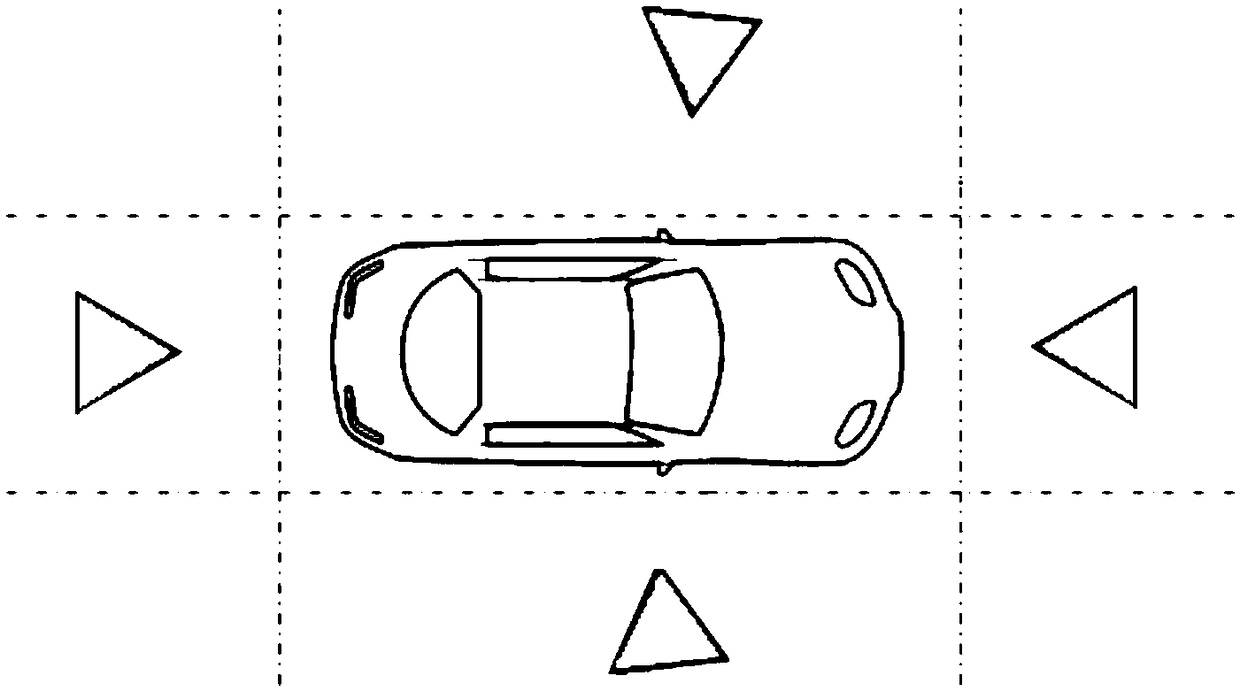

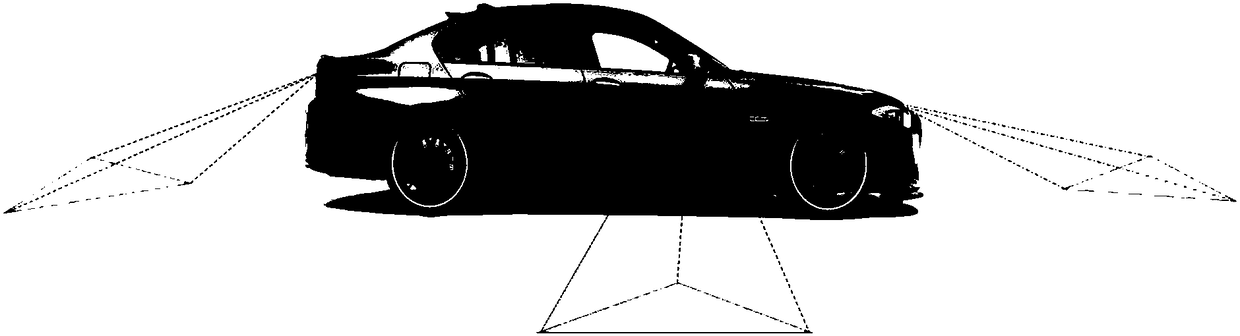

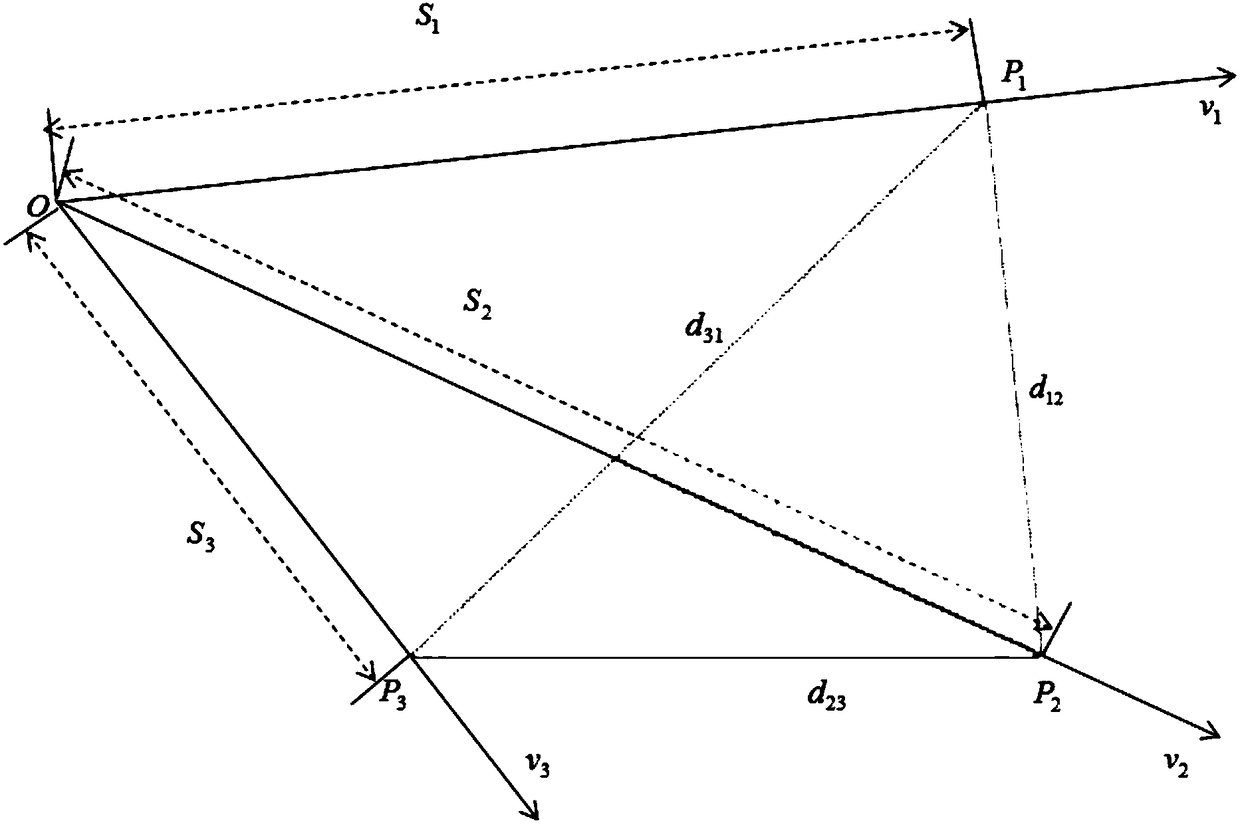

A processor for calibrating an automotive look-around system

ActiveCN109427077AEasy to collectOptimize layoutImage enhancementImage analysisPrior informationIsoetes triquetra

The present invention relates to a processor for calibrating an automotive look-around system, the automobile look-around system comprises a plurality of fish-eye cameras, the processor is configuredto execute the computer program steps of obtaining the rotation matrix Rt of the cameras, when the automobile stops, obtaining the observation vectors v1, v2 and v3 of the camera to three vertices ofa known marker under a camera coordinate system, and calculating a normal vector z of an equilateral triangle under the camera coordinate system according to a triangle side length and a spatial geometric relationship; when the vehicle moves along the X axis of the vehicle coordinate system, calculating the x axis unit vector of the camera coordinate system; calculating the rotation matrix of thecamera. Compared with the prior art, the process adopted by the processor of the invention makes full use of the potential prior information, the calibration scheme is simple, the calibration space required is small, the calibration precision is high, the anti-interference is stronger, and the requirement on the skill of the operator is greatly reduced to the extent that the driver can do it by himself.

Owner:DELPHI ELECTRONICS SUZHOU

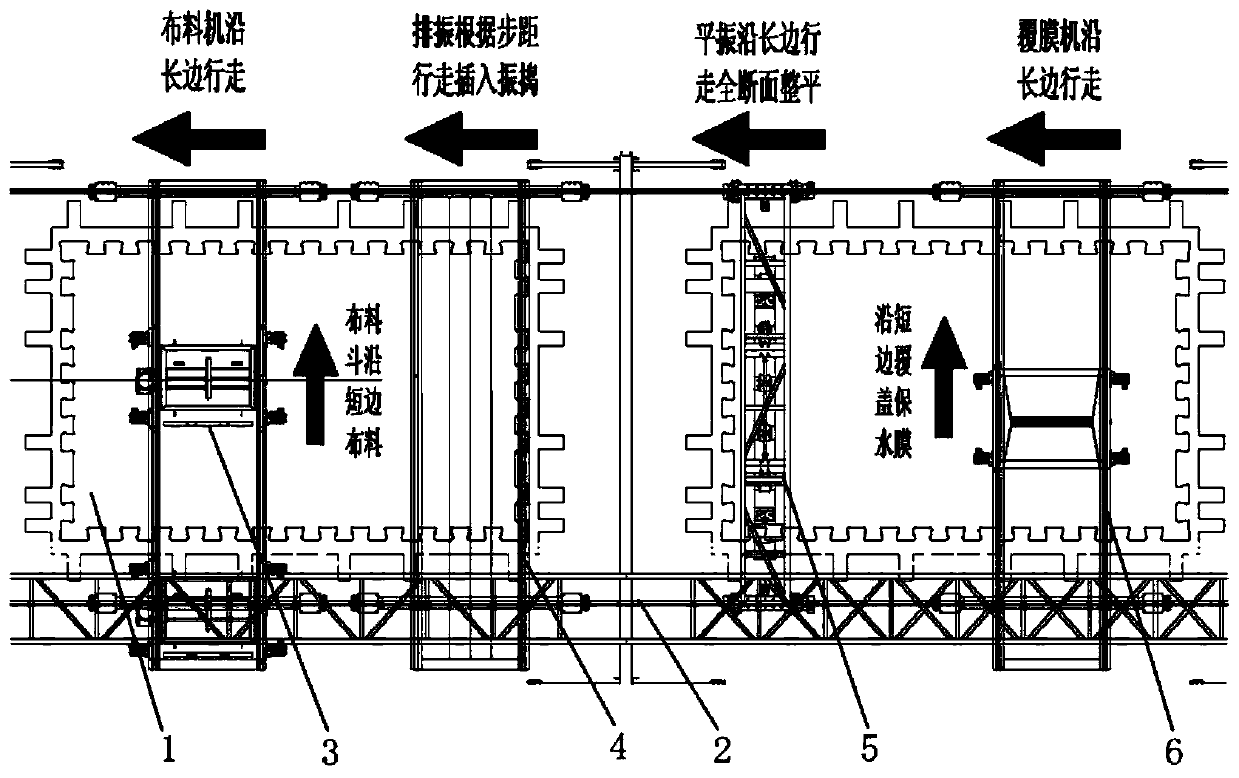

Control system and method of concrete bridge deck slab prefabricated slab production line

ActiveCN110757612AAvoid shortageAvoid problems with spacingFeeding arrangmentsAuxillary shaping apparatusBLENDER/MIXERProduction line

The invention discloses a control system and method of a concrete bridge deck slab prefabricated slab production line. The control system comprises a control center, a material distribution vibratingsystem, a concrete conveying system and a blender communication system. The material distribution vibrating system comprises a material distribution machine control subsystem, an insertion type vibrating control subsystem, a flat slab vibrating control subsystem and a rolling and film covering control subsystem. The material distribution vibrating system adopts event triggering. The concrete conveying system controls a mixture conveyer to convey concrete between the material distribution vibrating system and a blender. The blender communication system controls the blender to produce a corresponding amount of concrete according to feedback information of the material distribution vibrating system and sends a signal to the concrete conveying system after production. The control system and method of the concrete bridge deck slab prefabricated slab production line overcomes the technical problems that since the performance interval is long during pouring in the prior art, the pouring effect is influenced by environment change in the pouring interval process, and then the pouring effect is instable.

Owner:CCCC SHEC FOURTH ENG

Control method for smart homes

InactiveCN104460327AFulfill control requirementsEasy to carryComputer controlComputer hardwareMobile phone

The invention provides a control method for smart homes. The control method includes the six steps that a smart host, a terminal mobile phone and a control end mobile phone are arranged; a WeChat APP is installed on the terminal mobile phone; a WeChat APP is installed on the control end mobile phone; an instruction receiving account and a control account are added to each other as friends, and then an instruction is issued to the smart host through WeChat. Through the mobile phone WeChat, controlled electric appliances at home are controlled, carrying, learning and using are convenient, and the control method facilitates independent control operation of multiple persons.

Owner:湖州高鼎智能科技有限公司

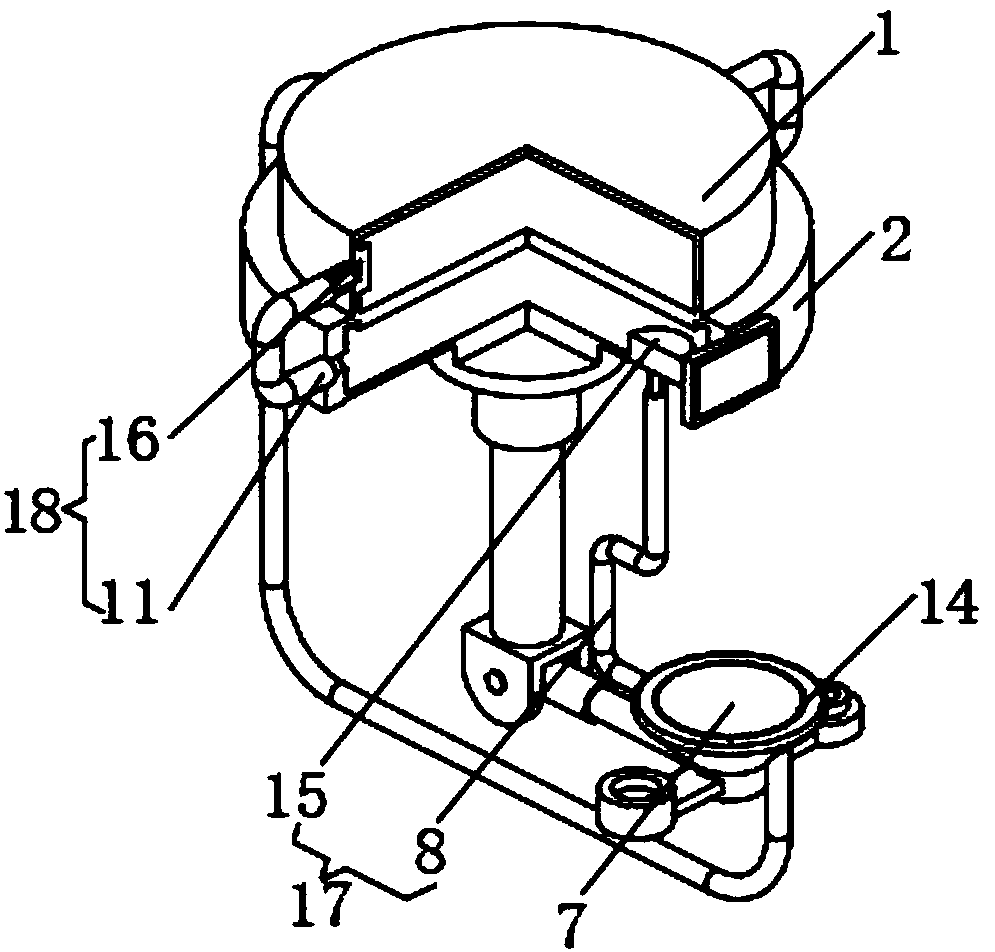

Circulating cold compress device for orthopedic care

InactiveCN108294858AHigh degree of intelligenceEasy to controlTherapeutic coolingTherapeutic heatingCold compressesOpen source

The invention discloses a circulating cold compress device for orthopedic care. The circulating cold compress device comprises a water tank, a condenser is installed on the top of the water tank, thecondenser is communicated with the water tank through a first delivering device, an adjusting mechanism is installed on the top of the condenser, a positioning device and a cold compress belt are installed at the ends of the adjusting mechanism respectively, a temperature sensor is installed on the cold compress belt, the cold compress belt is communicated with the condenser through a second delivering device, the cold compress belt is communicated with the water tank through a first spiral telescopic pipe, and an open source single-chip computer is installed on the side face of the condenser.According to the circulating cold compress device, positioning is conducted on the working position of the cold compress belt through a positioning device, the circulating cold compress device is high in intelligent degree and convenient to control and to be popularized, which is beneficial to the independent operation of a user, by conducting adjusting on the working position of the cold compress belt through the adjusting mechanism, the circulating cold compress device is good in flexibility and high in automation degree, and the workload of the user is greatly reduced to save time and labor.

Owner:杜志云

Feeding and discharging automatic hydraulic vulcanizing machine

The invention discloses a feeding and discharging automatic hydraulic vulcanizing machine. The machine comprises a vulcanizing machine body, a tire feeding device and a tire discharging device, wherein the tire feeding device and the tire discharging device are oppositely arranged on the two sides of the vulcanizing machine body; the vulcanizing machine body comprises a machine frame, an upper platform, a lower platform, a longitudinally-arranged guide column, a driving oil cylinder and a die activating oil cylinder, wherein an upper hot plate is arranged below the upper platform, a lower hotplate is arranged above the lower platform, and die opening and die closing control between the upper platform and the lower platform is achieved through the driving provided by the die activating oilcylinder and the driving oil cylinder; the tire feeding device comprises a tire feeding mechanical arm connected with the machine frame and a tire feeding conveying belt, and a limiting sensor is arranged at the side wall of the tire feeding conveying belt; and the tire discharging device comprises a tire discharging mechanical arm connected with the machine frame and a tire discharging conveyingbelt, and displacement sensors are arranged on drive oil cylinders of the tire feeding mechanical arm and the tire discharging mechanical arm correspondingly. The machine is simple in structure, highin automation degree, convenient to operate and capable of realizing the automatic control of a series of processes including tire feeding, shaping, vulcanizing, tire discharging and the like, so that the vulcanizing efficiency is greatly improved.

Owner:南京龙贞自控科技发展有限公司

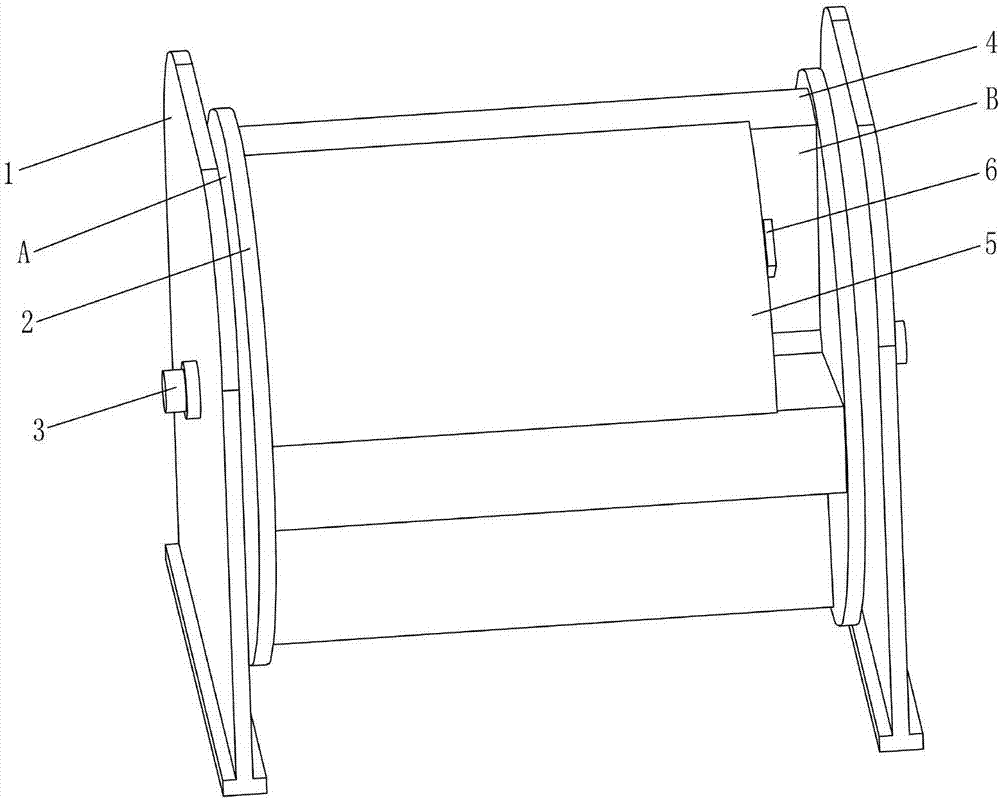

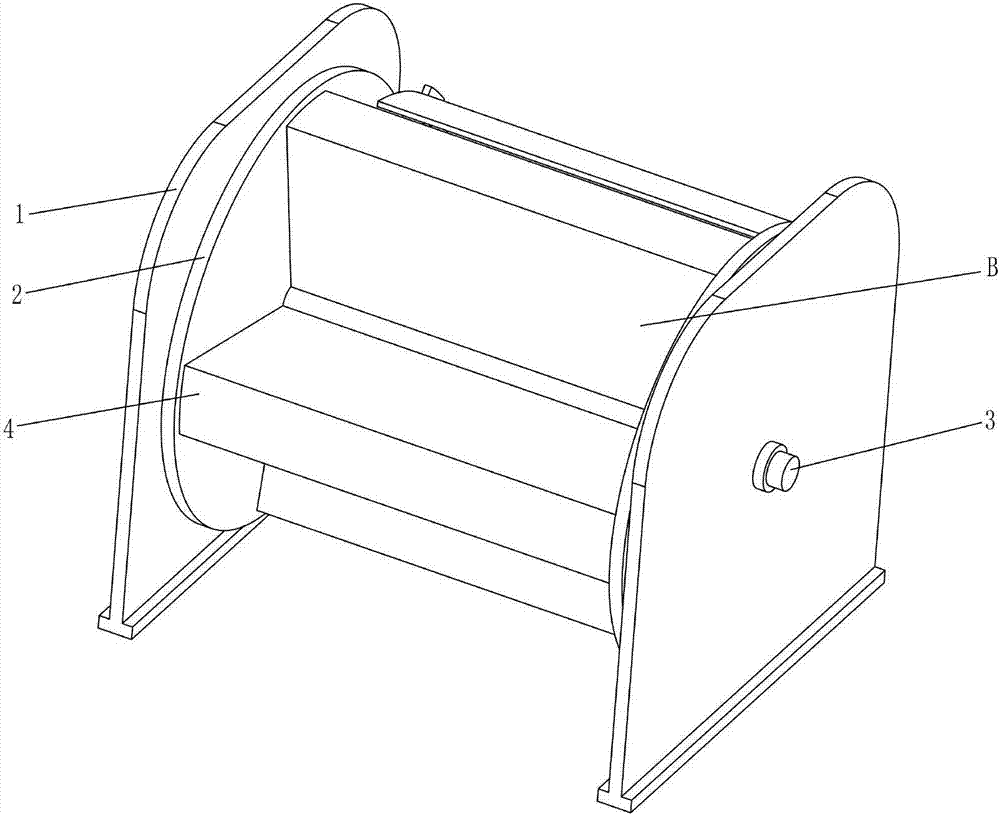

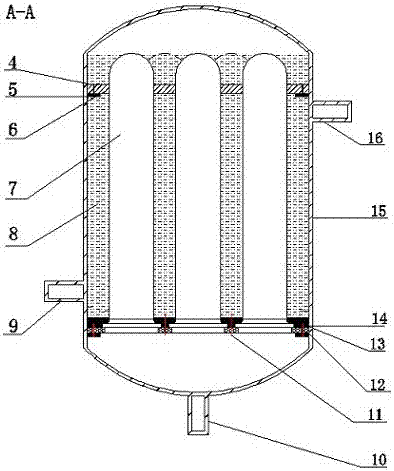

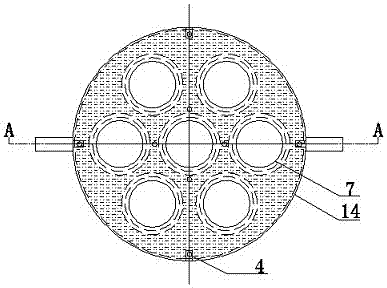

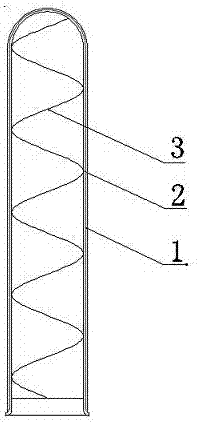

Test-tube membrane component and membrane accumulator with same

PendingCN107362689ASimple structureAvoid deformationMembranesSemi-permeable membranesTest tubeOrifice plate

The invention relates to a test-tube membrane component and a membrane accumulator with the same, belongs to the technical field of energy storage, and is intended to effectively solve the problem that an existing accumulator has low energy accumulation density and low practicality and economy. The membrane accumulator comprises fixing bolts, positioning plates, support orifice plates, test-tube membrane components, porous supports, a support framework, a solution, a solution outlet connection tube, a solution inlet connection tube, a steam connection tube, fastening bolts, a lower sealing orifice plate, sealing filler, an upper sealing orifice plate, and a housing. When the membrane accumulator experiences inside crystal, water vapor may enter the solution via a semipermeable membrane of the membrane component, the crystal absorbs the water vapor so as to be diluted, and heat released increases the crystal dissolving speed. When enhancing heat transfer and mass transfer efficiency is required, more test-tube membrane components can be added in the accumulator via simple operations so as to arrive at enhancement. The test-tube membrane component and the membrane accumulator are simple in structure, good in operational reliability, good in crystallization resistance, and high in energy accumulation density, and mass transfer efficiency can be enhanced via simple operations.

Owner:QINGDAO UNIV +1

Medical hydraulic elevating nursing bed

InactiveCN106913429AIncrease storage spaceEasy to operate independentlyNursing bedsEngineeringBed boards

The invention discloses a medical hydraulic elevating nursing bed, comprising a bed body, supports, a dining table, and a controller. The position of each two adjacent supports, close to ground, is connected with a storage plate. A cavity is provided with drawers through a plate. Two side edges of a first bed board are provided with first sliding rails. Each group of the first sliding rail is provided with two first sliding blocks. Each first sliding block is connected with a sleeve, and is connected with a brace. Each brace is slidably connected with the sleeve. A lamp support on the side edge of the dining table is connected with an illuminating lamp. A base is fixedly connected with a connecting rod. The other end of the connecting rod is connected with an elevating rod through a second rotating shaft. The other end of the elevating rod is slidably connected with a sliding rail on the back surface of a second bed board through a second sliding block. The medical nursing bed is large in storage space and convenient in autonomous operation by a patient, and provides a comfortable and tidy ward for a patient.

Owner:CHONGQING TONGHEZHI AGRI INTEGRATION DEV CO LTD

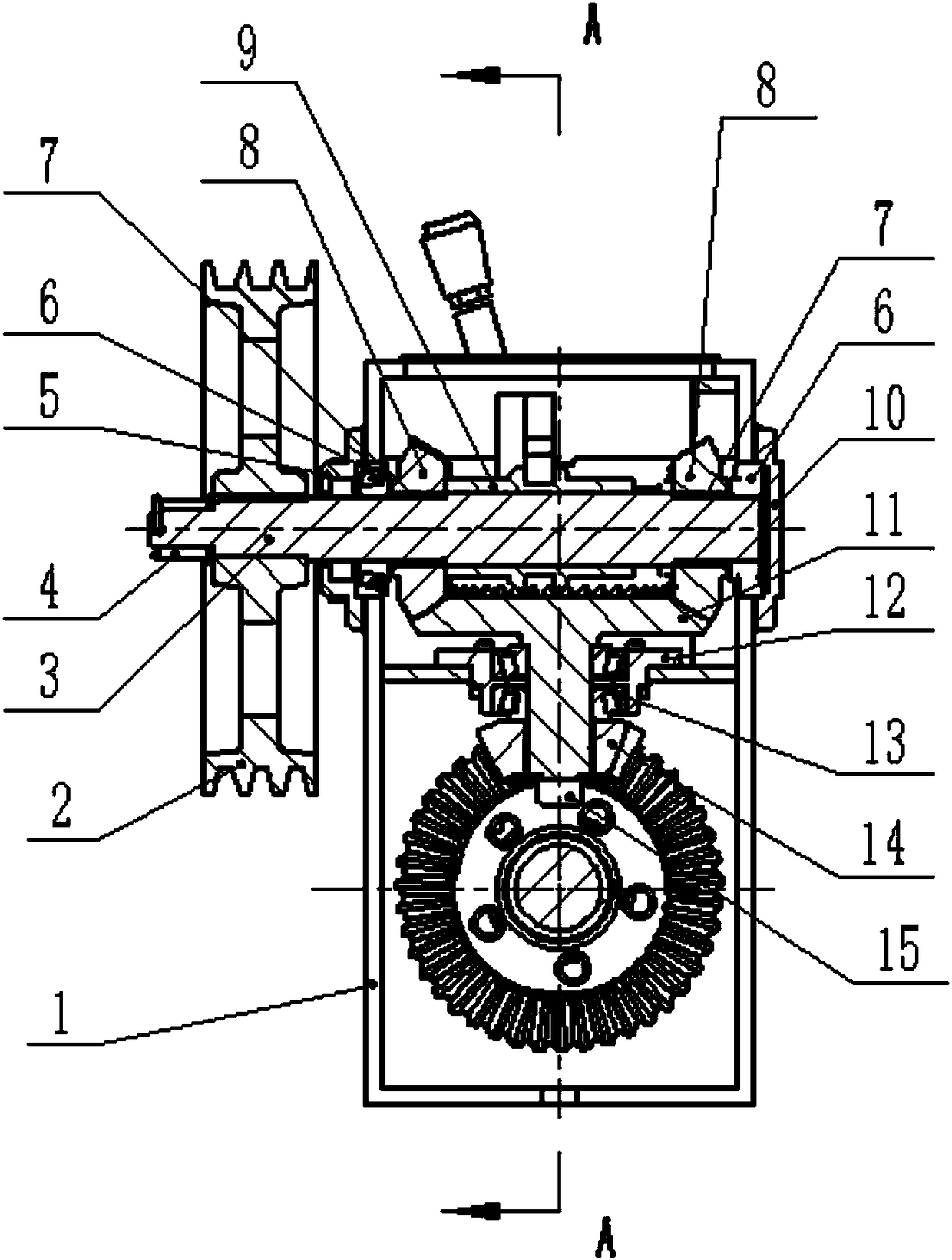

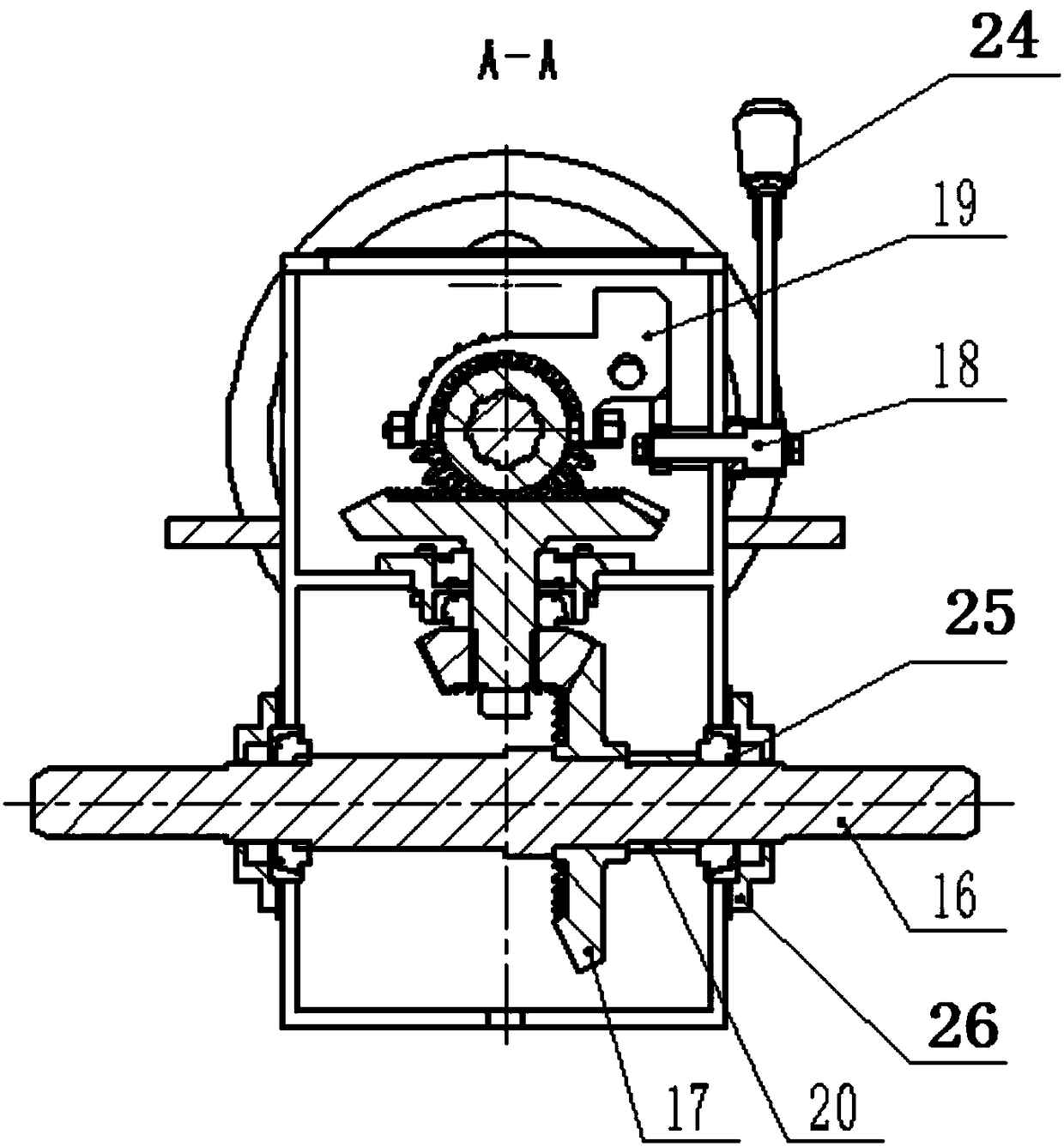

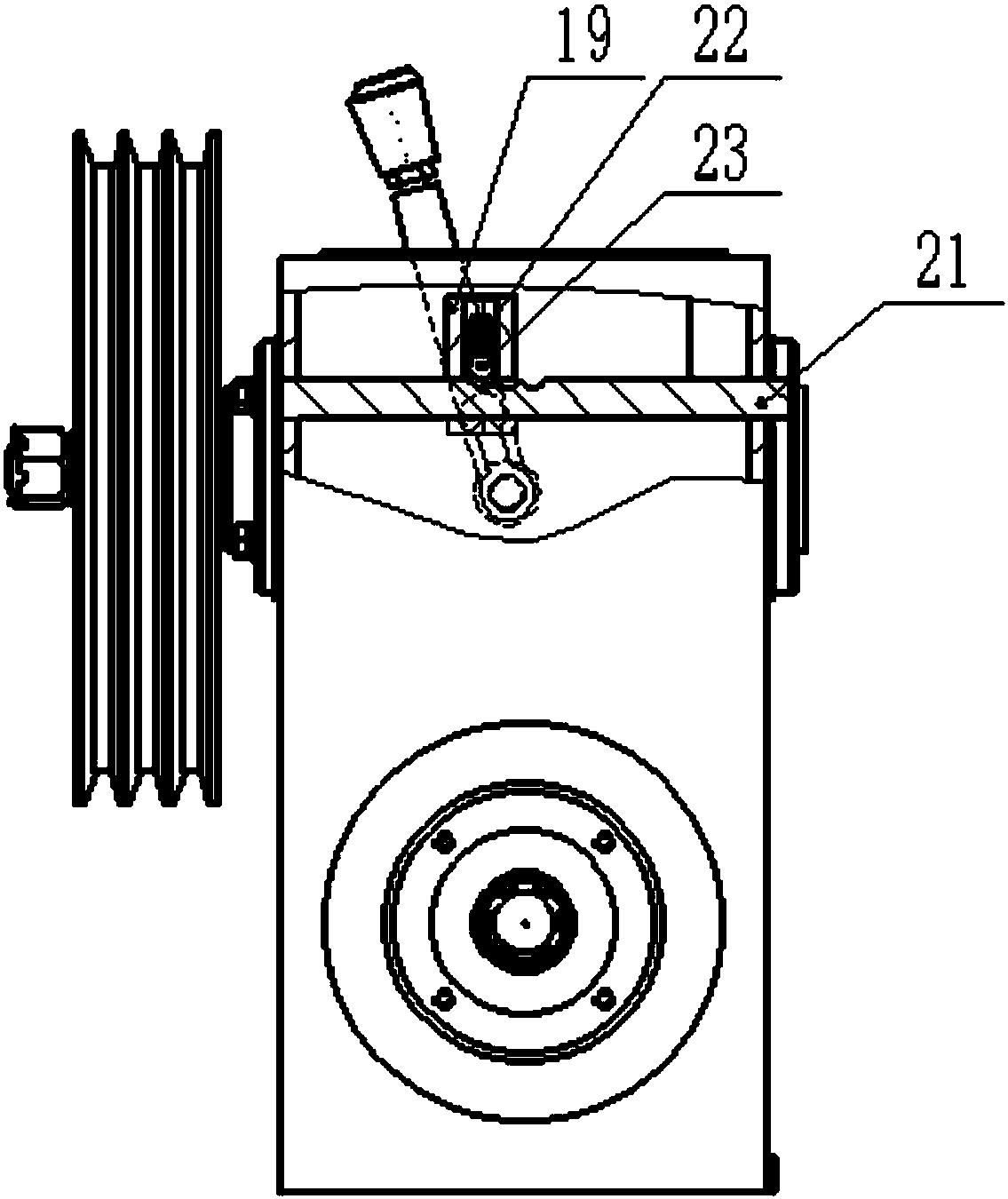

Power rotation-angle output case capable of achieving positive and negative rotation

PendingCN108105345AGuaranteed uptimeMeet multi-purpose needsToothed gearingsTransmission elementsTurn angleControl theory

The invention discloses a power rotation-angle output case capable of achieving positive and negative rotation. The power rotation-angle output case comprises an input shaft and an output shaft, wherein the input shaft and the output shaft are arranged in a crossed manner. A gear-shifting sliding sleeve is mounted on the input shaft. Input shaft bevel gears are mounted at the two sides of the gear-shifting sliding sleeve through copper sleeves. A middle shaft large bevel gear and a middle shaft small bevel gear are mounted between the input shaft and the output shaft, wherein the middle shaftlarge bevel gear is coaxial with the middle shaft small bevel gear. The middle shaft large bevel gear is engaged with the input shaft bevel gears. The middle shaft small bevel gear is engaged with anoutput shaft bevel gear mounted on the output shaft. A gear shifting fork is arranged at the outer side of the gear-shifting sliding sleeve and mounted on a shifting fork connecting rod in a sleevingmanner. The shifting fork connecting rod is provided with three grooves. The gear shifting fork is provided with a clamping pin and a compression spring, wherein the clamping pin can be clamped into the grooves, and the compression spring jacks the clamping pin in a pressing manner. The gear shifting fork is shifted by a gear-shifting mandrel assembly to move leftwards and rightwards. The gear-shifting mandrel assembly is connected with a gear-shifting handle. By means of the power rotation-angle output case, 90-degree power reversing, positive and negative rotation power steady output and forward and backward double-power output can be achieved; the power rotation-angle output case runs reliably; and the multi-purpose requirement can be met.

Owner:GUANGXI LANGUANG TECH

New energy automobile charging pile

InactiveCN113335112AInhibit sheddingImprove adsorption capacityCharging stationsElectric vehicle charging technologyNew energyStructural engineering

The invention discloses a new energy automobile charging pile which comprises a fixing mechanism, a contraction mechanism, an auxiliary mechanism and a protection mechanism. One end of the fixing mechanism is fixedly connected with one end of the contraction mechanism, the auxiliary mechanism is located in the contraction mechanism, and the contraction mechanism is located in the protection mechanism; the new energy automobile charging pile can effectively prevent a charging head from falling off during charging, a fixing plate makes contact with the inner wall of an automobile charging cavity, plugging and pulling are facilitated, under the action of a telescopic spring and a clamping plate, the device is suitable for fixing the automobile charging cavities with different depths, vibration driven by the outside of the device is reduced and the phenomenon that the connector falls off is prevented. Through sealing of the rainproof cover, charging interruption caused by the fact that the connector is stained with water is prevented, meanwhile, under the action of the rubber suction cup, the rainproof cover and the shell of the automobile can be firmly adsorbed, the interior of the rainproof cover is in a sealed state through the sealing ring, and the water suction ring and the drying ring can prevent the water inflow phenomenon.

Owner:LUOHE VOCATIONAL TECH COLLEGE

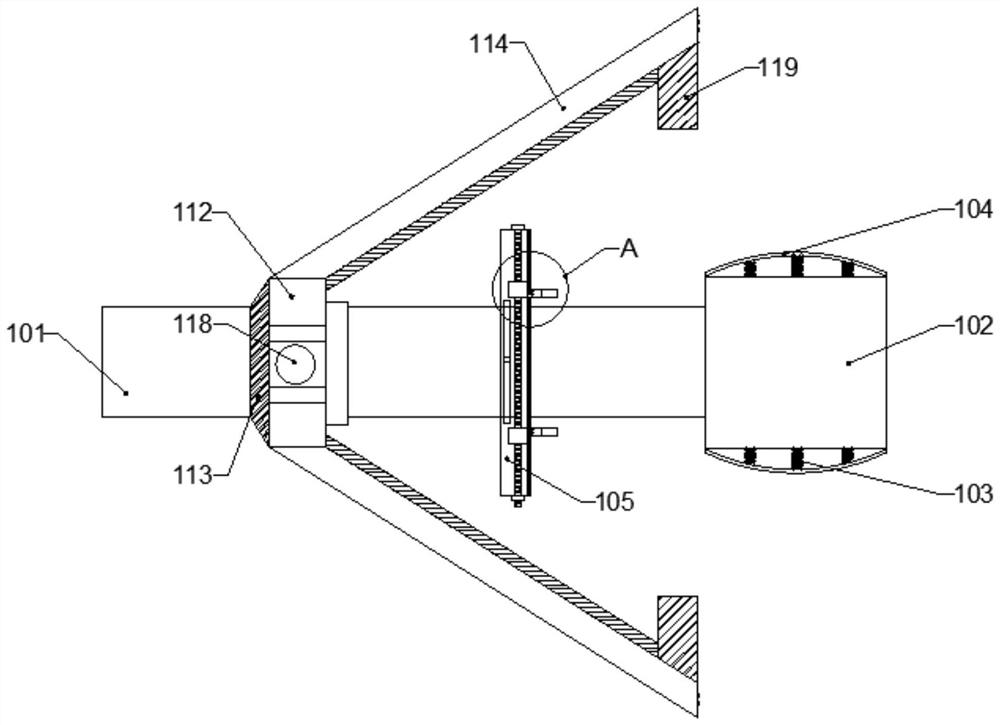

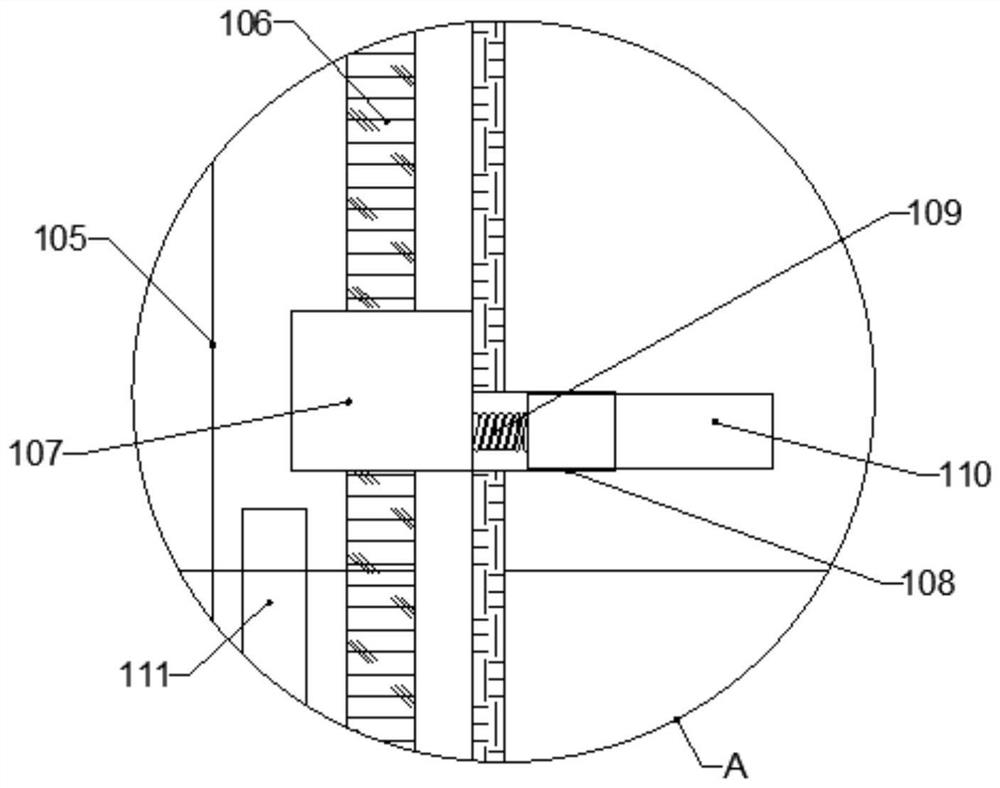

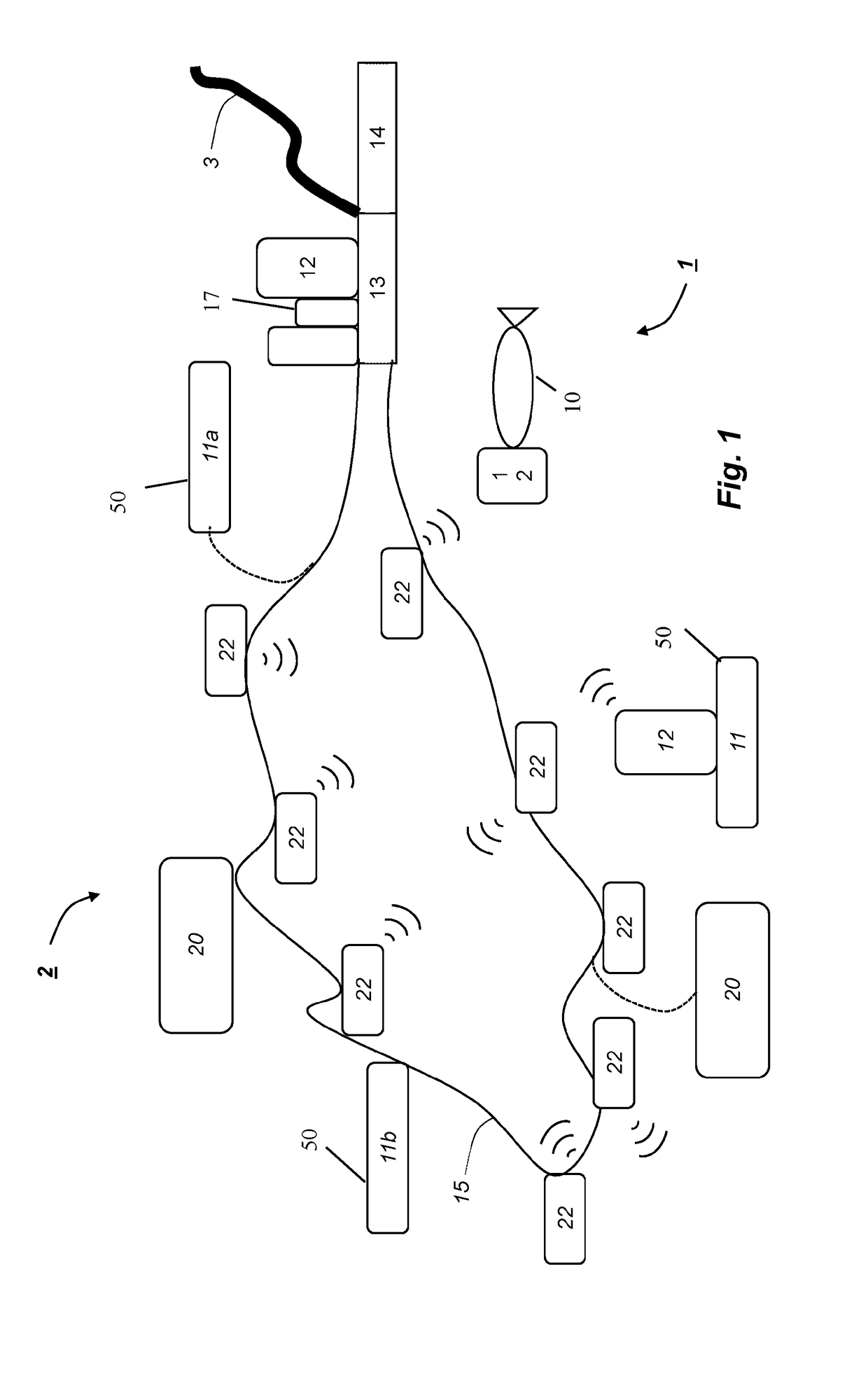

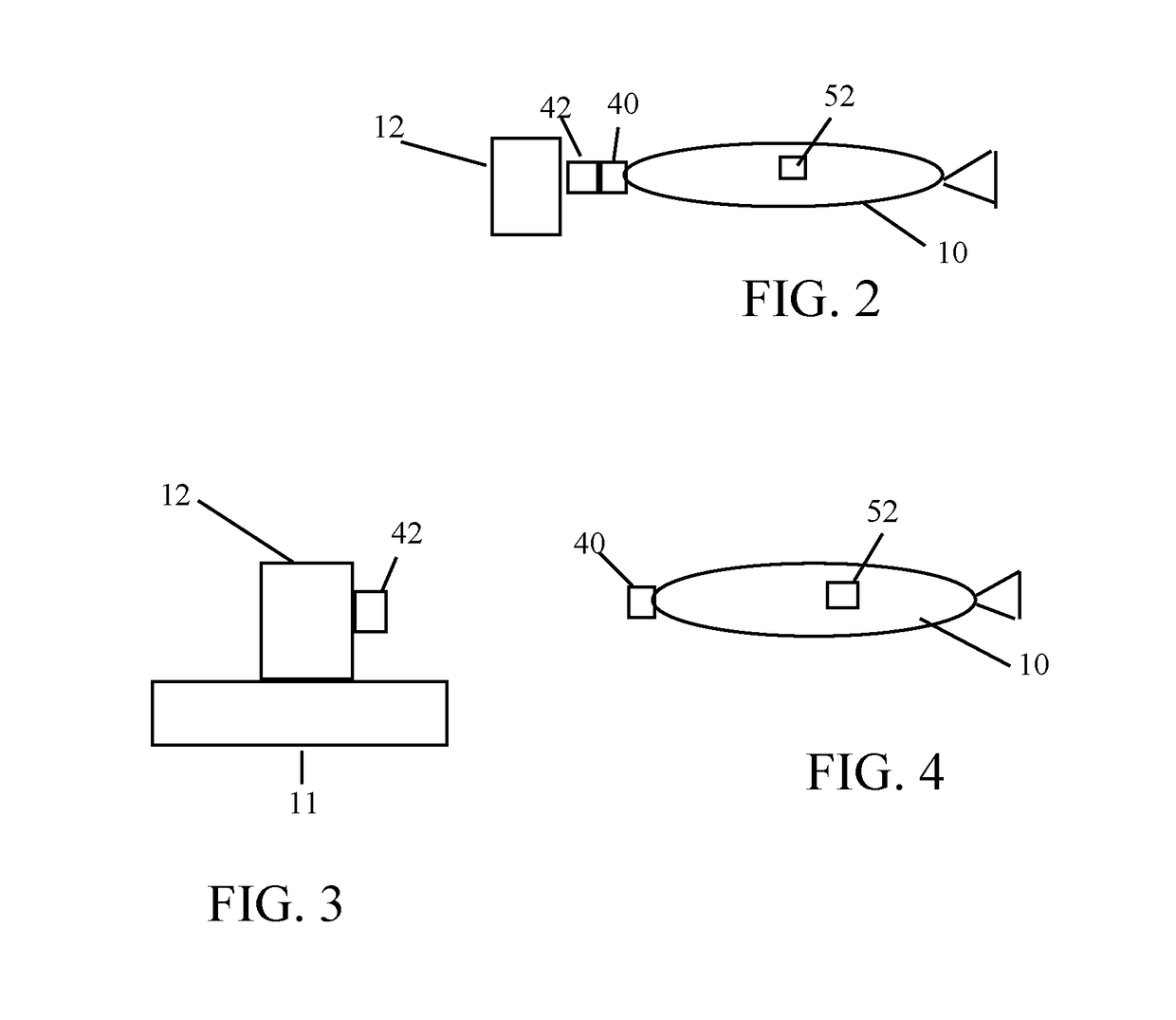

System and method for operating a subsea sensor field

ActiveUS10191172B2Accuracy is lostReduce stepsSeismic signal receiversSeismology for water-covered areasMarine engineeringInstalled base

A system (1) for operating a subsea sensor field (2), comprises an automated underwater vehicle—AUV (10) and a subsea service station (13). A sensor (11, 12) in the sensor field (2) comprises a permanently installed base unit (11) and a removable control unit (12). The AUV (10) moves control units (12) to the service station (13) for charging and updating, and then back to the base units.

Owner:OCTIO

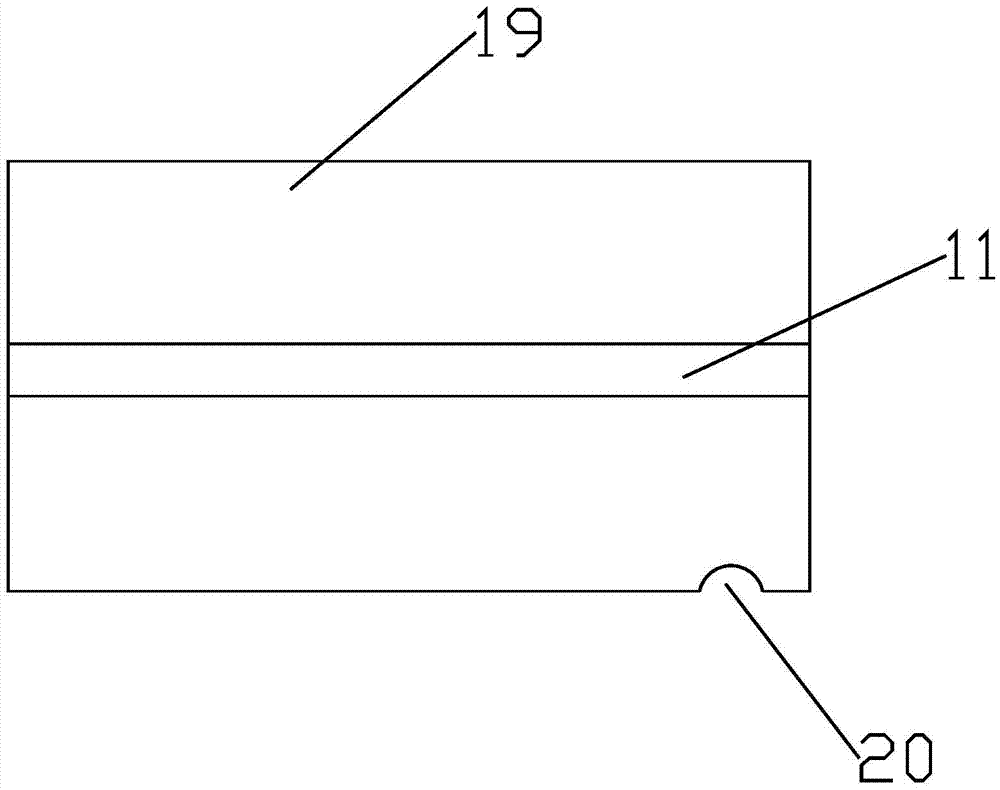

Portable network hard disk memory

InactiveCN106920565ASo as not to damageImprove cooling effectCarrier casesRecord information storagePush pullEngineering

The invention belongs to the technical field of computers and particularly relates to a portable network hard disk memory. The interior of a shell is divided into a cavity A, a cavity B and a cavity C; the cavity B is located between the cavity A and the cavity C; a push-pull box is arranged in the cavity A; sliding ways are arranged on two sides of the push-pull box; convex ribs matched with the sliding ways are arranged on the inner wall of the cavity A; a circuit board is arranged in the push-pull box; long slots are formed in the left and right sides and the lower bottom surface of the circuit board; support columns matched with the long slots are arranged on the inner wall of the push-pull box; support plates are arranged on two sides of each support column; a groove is further formed in the lower bottom surface of the circuit board; a fan is vertically arranged in the cavity B; the internal structure of the cavity C is the same as that of the cavity A; a carrying handle is arranged at the top of the shell; an independent switch door is arranged on a door plate and matched with the push-pull box; and a switch handle is arranged on the independent switch door.

Owner:天津东恩餐饮管理有限公司

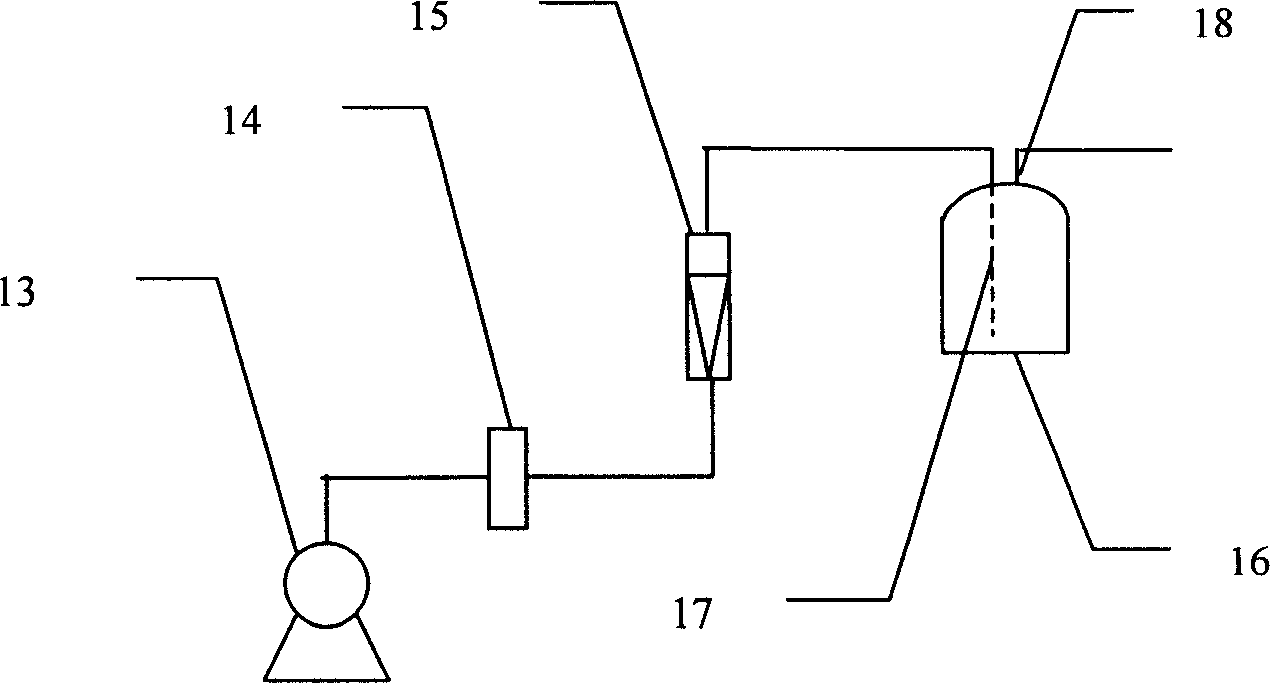

Energy-saving environment-friendly liquid slag removal type coal-fired heating system

ActiveCN101825276AEmission reductionImprove combustion efficiencyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelAir preheaterCombustion chamber

The invention discloses an energy-saving environment-friendly liquid slag removal type coal-fired heating system, which comprises a pulverized coal feeding device, an air distribution device, an ignition device, a liquid and slag collection device, a burning-out chamber, a high-temperature air preheater, a plurality of air and smoke pipes and a vertical liquid slag removal type pulverized coal combustor, wherein the vertical liquid slag removal type pulverized coal combustor is communicated with the burning-out chamber. The pulverized coal inlet, the oil inlet and the air inlet of the combustor are respectively connected with the pulverized coal feeding device, the ignition device and the air distribution device through pipes. A secondary prewhirling chamber, a combustion chamber and a slag removal chamber are sequentially and vertically communicated in the combustor. The slag removal chamber is connected with a liquid collection device. The side wall of the lower part of the combustion chamber is horizontally and axially communicated with a combustor flame outlet which is arranged in a direction consistent with secondary air whirling direction and is tangent with the inner wall surface of the combustor. The outlet of the combustor flame outlet is connected with a high-temperature smoke inlet. A high-temperature smoke outlet is arranged at the top end of the burning-out chamber and the bottom end of the burning-out chamber is connected with a solid slag collection section. The high-temperature air preheater is arranged on the high-temperature smoke outlet. Moreover, the system additionally comprises a heat supply pipe communicated with the high-temperature air preheater. The entire coal-fired heating system is connected with a heating device through the heat supply pipe arranged above the high-temperature air preheater.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

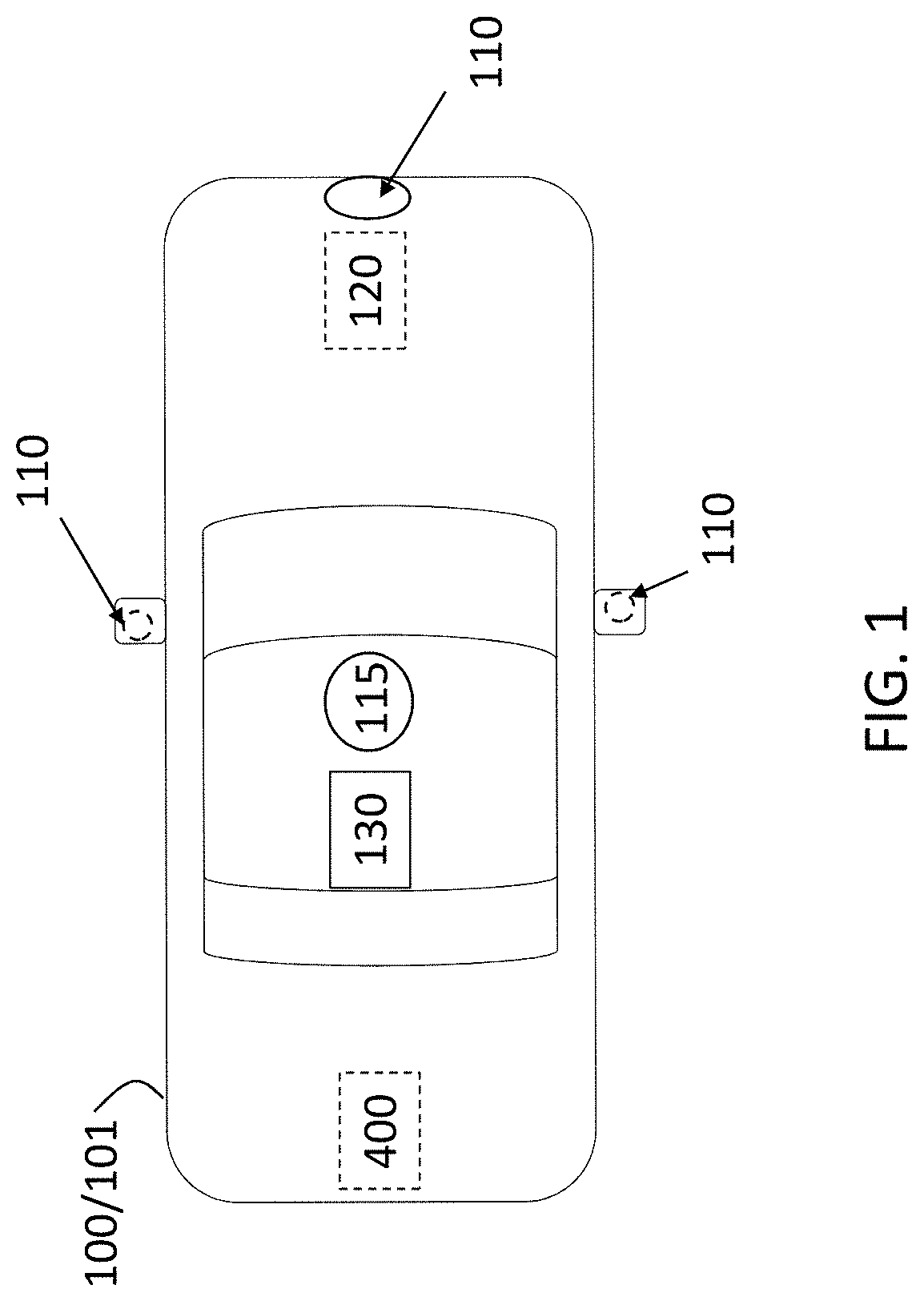

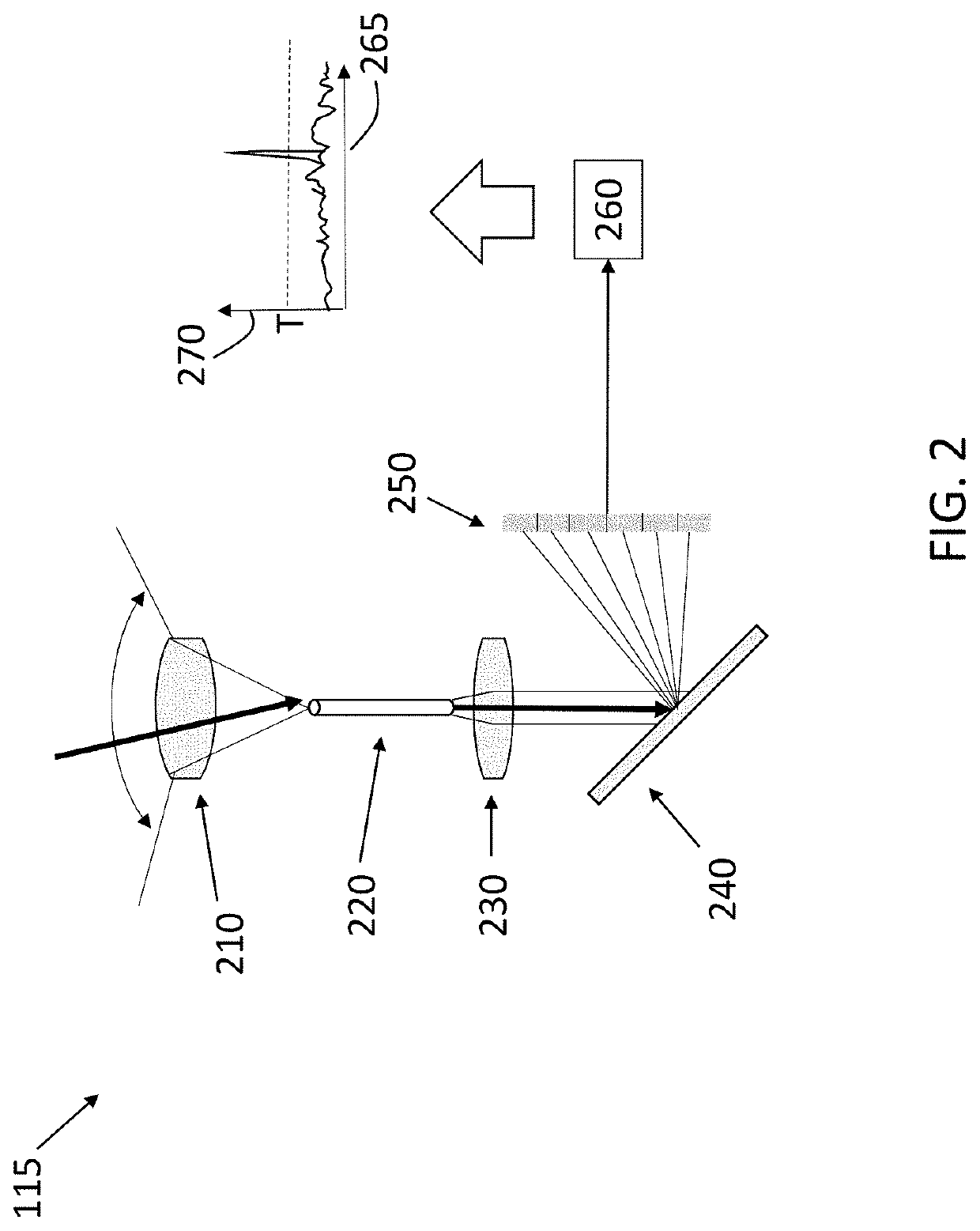

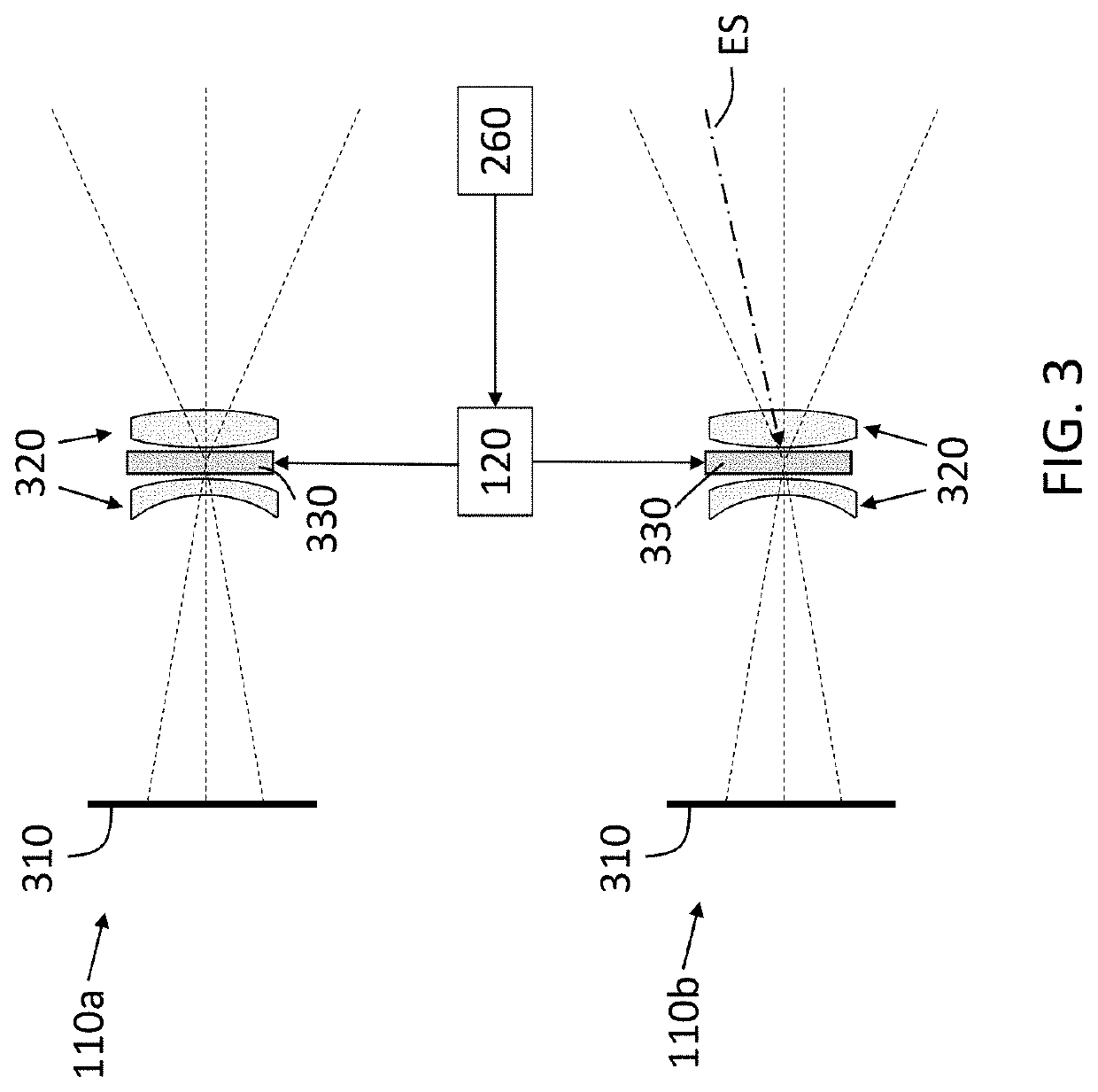

Mitigation of errant signal effects on an image sensor of a vehicle

ActiveUS10814799B1Reduce the impactReduce signalingSpectrum investigationPhotometrySignal onEngineering

Systems and methods to mitigate an effect of an errant signal on an image sensor of a vehicle involve collecting light and separating the light to obtain signals at different wavelengths. A method includes determining an intensity of the light at each of the different wavelengths, and identifying the errant signal based on the intensity of the light exceeding a threshold value at an errant signal wavelength among the different wavelengths. The errant signal is mitigated using the controller.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com