Culturing system of external light biological reactor for plant tissue cutter

A photobioreactor and bioreactor technology, applied in the field of culture systems, can solve the problems of inability to realize continuous long-term photobioreactor cultivation, increase the microbial contamination rate, cutting work, and affect the smooth progress of experiments, and achieve easy independent operation, Improve the effect of scientificity and easy disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

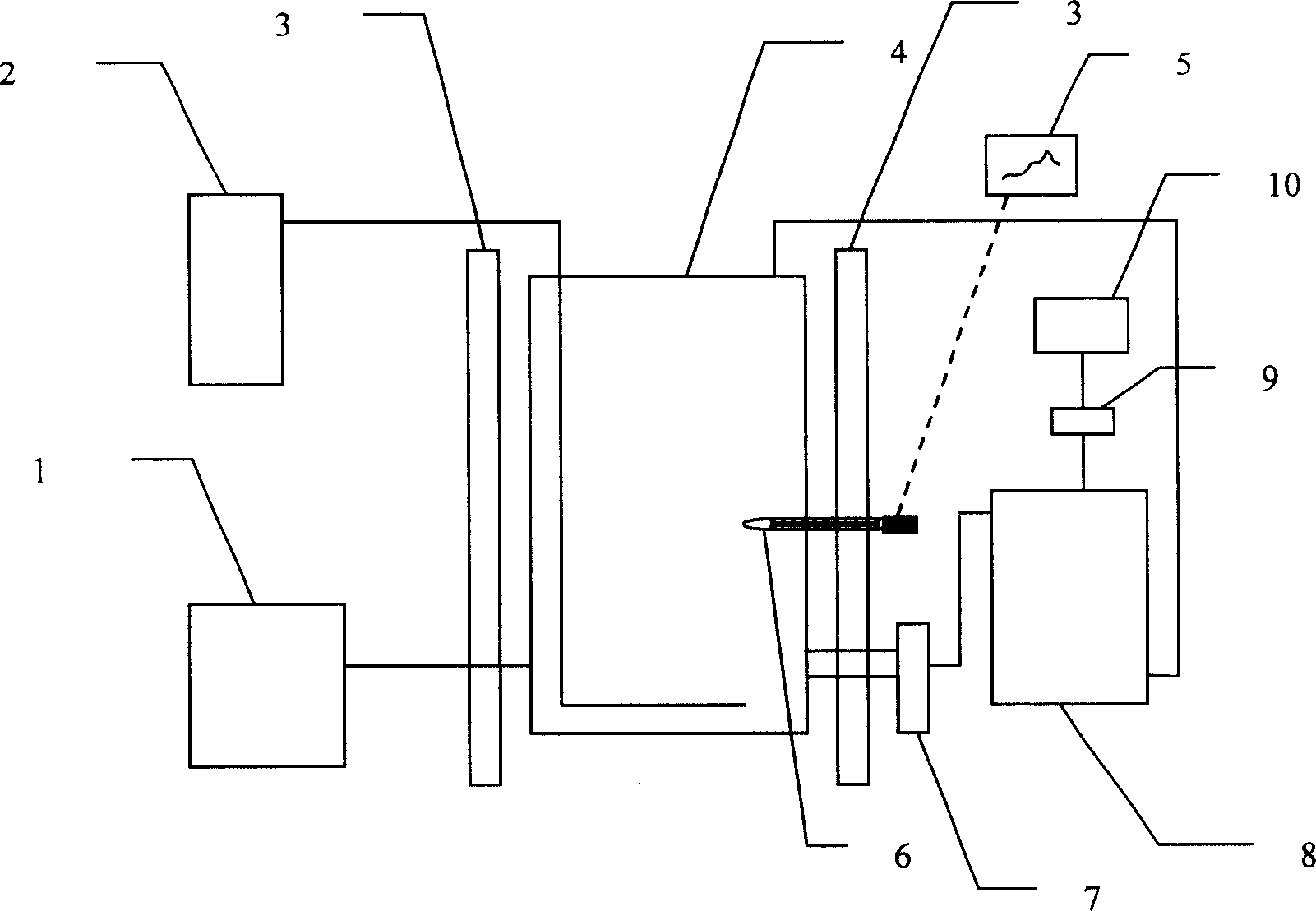

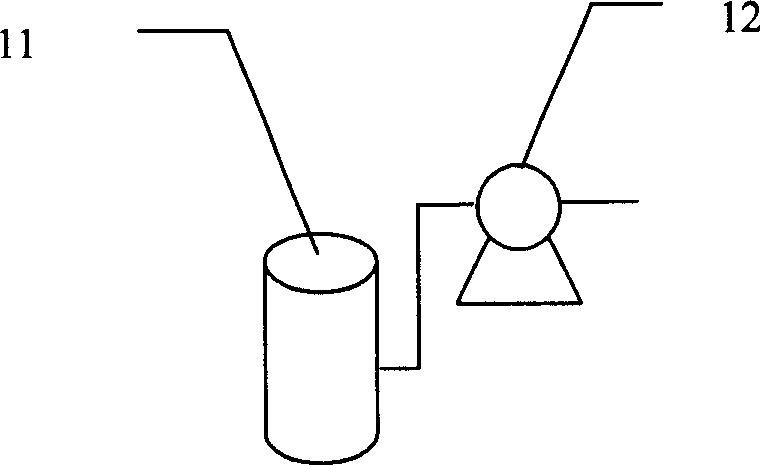

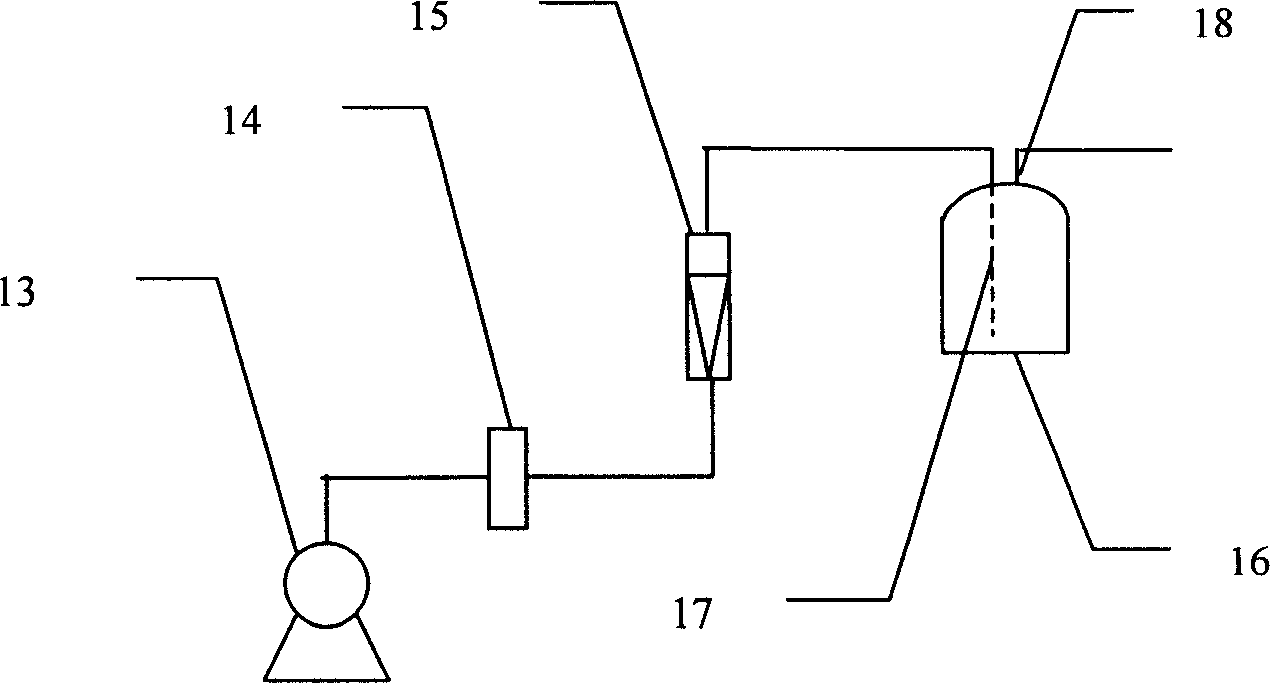

[0025] Such as Figure 1-8 As shown, the present invention includes: an infusion system 1, a gas delivery system 2, an illumination system 3, a bioreactor cultivation system 4, a data receiving processor 5, an online photosensitive monitor 6, a three-way device 7, a cutting system 8, a first Air filter 9, vacuum / pressure dual-purpose pump 10. The connection method is as follows: the infusion system 1 is connected to the bioreactor cultivation system 4 through a silicone tube; the gas delivery system 2 is connected to the bioreactor cultivation system 4 through a silicone tube; the lighting system 3 is fixed on the periphery of the bioreactor cultivation system 4; The photosensitive monitor 6 is installed on one side of the photobioreactor cultivation system 4, and transmits the signal to the data receiving processor 5; the three ends of the three-way device 7 are respectively connected to the two interfaces and the cutout of the bioreactor cultivation system 4 through silicone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com