Energy-saving environment-friendly liquid slag removal type coal-fired heating system

A heating system, energy saving and environmental protection technology, which is applied in the combustion of various fuels, the combustion of block fuel and liquid fuel, the combustion of liquid fuel and gaseous fuel, etc., can solve the problem of long ignition time and distance, energy consumption, etc. , increase investment costs and other issues, to achieve the effects of high combustion efficiency and thermal efficiency, convenient system operation and maintenance, and adjustable heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

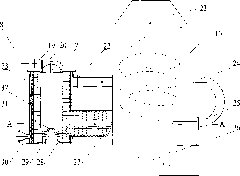

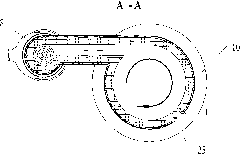

[0026] see Figure 1 to Figure 3 As shown, an energy-saving and environment-friendly liquid slag discharge type coal-fired heating system includes a powder feeding device, an air distribution device, an ignition device, a liquid slag collecting device 7, a burnout chamber 10, a high-temperature air preheater 15 and a plurality of The wind and smoke pipeline also includes a vertical liquid slag discharge pulverized coal burner 8 communicated with the burnout chamber 10, and the inlets of the pulverized coal, oil, and air of the burner 8 are respectively connected with the powder feeding device, the ignition device, and the air distribution device through the pipeline. Connection; the powder feeding device includes a coal mill 1, a pulverized coal bin 18, a fluidizer, a feeder, an air compressor 2, a pneumatic conveying injector and a supporting pulverized coal conveying pipeline 16; the air distribution device includes blowers connected to each other 3. Air distribution chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com